Aluminum Insulation Sheets - PVC Aluminium Foil Laminating Extruder PE Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of PVC aluminium Foil Laminating Extruder PE Coated Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the PVC aluminium Foil Laminating Extruder PE Coated:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

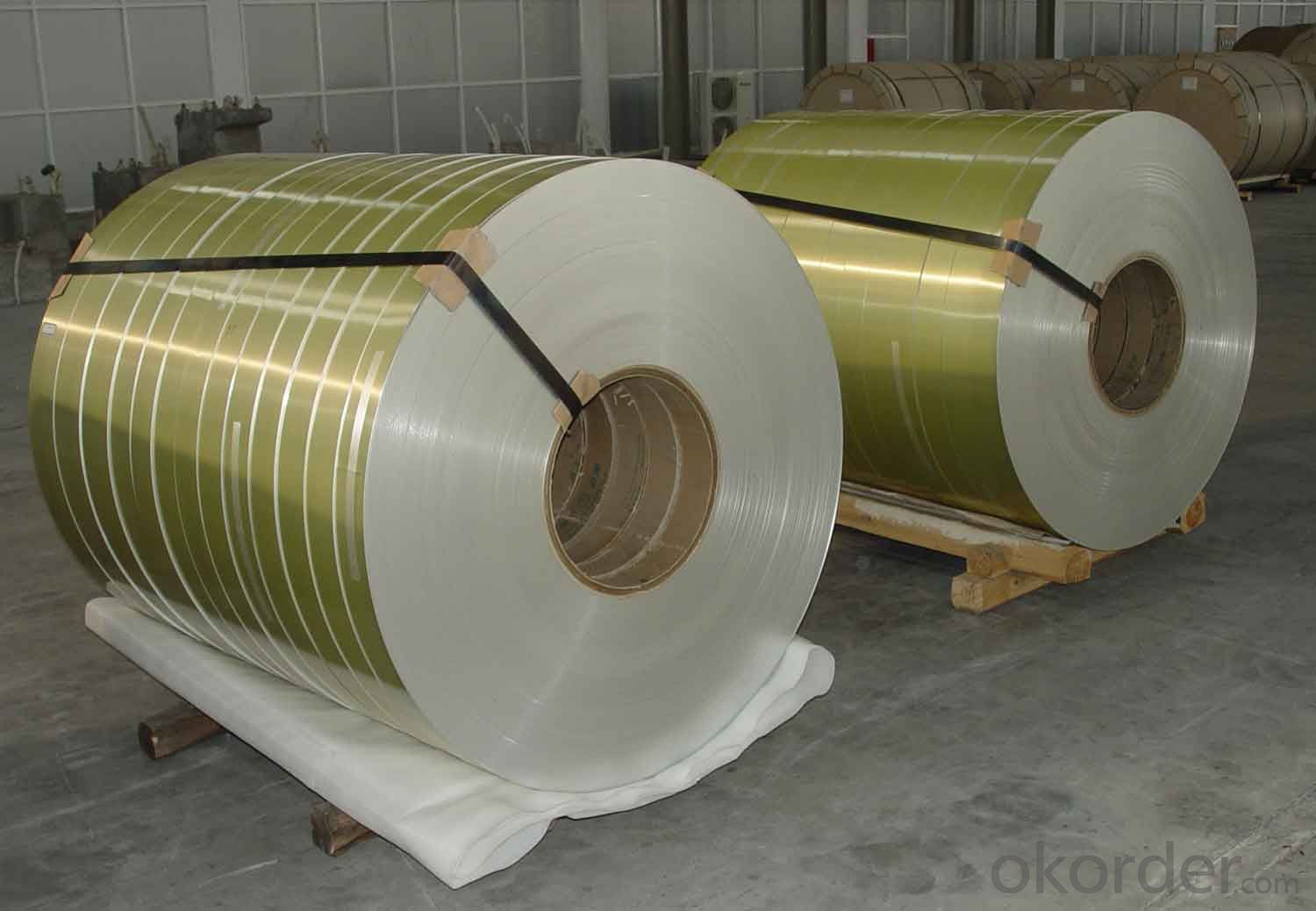

Images of PVC aluminium Foil Laminating Extruder PE Coated:

Aluminium Pre-painted Coil Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum sheets be used for industrial shelving?

- Certainly, industrial shelving can indeed make use of aluminum sheets. Aluminum, being a material that is lightweight and durable, offers numerous benefits for industrial shelving applications. It possesses resistance against corrosion, making it suitable for environments that face exposure to moisture or harsh chemicals. Moreover, the strength-to-weight ratio of aluminum proves advantageous, enabling the creation of robust shelves capable of supporting heavy loads while remaining relatively light in weight. Furthermore, aluminum is low-maintenance as it does not necessitate painting or sealing like other metals. Consequently, aluminum sheets are an incredibly practical option for industrial shelving due to their durability, resistance to corrosion, and lightweight characteristics.

- Q: I have a friend to purchase a number of aluminum, used to make computer cooling plate. He asked me to help with the supplier, can I look at the Internet, there are many kinds of aluminum, would like to ask: what kind of computer cooling plate used to do a bit better? What are the suitable suppliers in Guangdong?

- Aluminum extruded radiator:It is widely used in modern material with good heat dissipation cooling industry, most of them use 6063 T5 high quality aluminum, its purity can reach above 98%, the heat conduction ability, low density, low price so get the favor of the major manufacturers.

- Q: Are the aluminum sheets suitable for manufacturing architectural ceiling panels?

- Yes, aluminum sheets are suitable for manufacturing architectural ceiling panels. Aluminum is known for its durability, lightweight nature, and resistance to corrosion, making it an ideal material for architectural applications. It can be easily shaped and formed into various panel designs and sizes, offering flexibility in creating unique ceiling designs. Additionally, aluminum sheets are available in different finishes and colors, allowing for customization to meet specific design requirements. Overall, aluminum sheets provide a cost-effective and aesthetically pleasing solution for manufacturing architectural ceiling panels.

- Q: I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q: What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- Metal plate curtain wall deformation resistance is poor, the plate strength and steel are not high enough, waterproof sealing performance is not good enough, easy to fade, deformation, also can cause light pollution. Construction and installation technical requirements are relatively high.Stone curtain wall is now used most, but more stereotyped, and negative news constantly, stone fell, heavy stones, high-rise building exterior wall of high risk, poor fire performance.

- Q: What are the advantages of using aluminum sheets in automotive applications?

- There are several advantages of using aluminum sheets in automotive applications. Firstly, aluminum is lightweight, which helps improve fuel efficiency and overall vehicle performance. Secondly, aluminum has high strength-to-weight ratio, making it durable and resistant to corrosion. This ensures a longer lifespan for automotive components made from aluminum sheets. Additionally, aluminum is easily recyclable, making it an environmentally friendly choice. Lastly, aluminum sheets can be easily formed and molded into complex shapes, allowing for greater design flexibility in automotive manufacturing.

- Q: Are aluminum sheets suitable for food storage applications?

- Yes, aluminum sheets are suitable for food storage applications. Aluminum is a widely used material in the food industry because it is lightweight, durable, and has excellent thermal conductivity properties. Aluminum sheets are often used to make food storage containers, foil wrap, and trays. These sheets provide an effective barrier against moisture, oxygen, and light, which helps to preserve the freshness and quality of food. Additionally, aluminum is non-toxic and does not react with acidic or alkaline food, ensuring that the taste and safety of the stored food are not compromised.

- Q: Can aluminum sheets be bent or formed?

- Yes, aluminum sheets can be bent or formed. Aluminum is a highly malleable and ductile metal, which means it can easily be shaped or bent without breaking. This characteristic makes it a popular choice for various applications, such as manufacturing automotive parts, aircraft structures, and household items. Aluminum sheets can be bent or formed using various techniques, such as press braking, roll bending, and stretch forming. These methods allow the aluminum sheets to be shaped into different angles or curves to meet specific design requirements.

- Q: Are 101 aluminum sheets suitable for mold making?

- No, 101 aluminum sheets are generally not suitable for mold making. While aluminum is a commonly used material for making molds due to its durability and heat resistance, 101 aluminum is a low-strength alloy that may not meet the requirements for mold making. For such purposes, it is recommended to use aluminum alloys with higher strength and hardness, such as 6061 or 7075 alloys. These alloys offer better resistance to wear, deformation, and heat, making them more suitable for creating molds that can withstand the pressures and temperatures involved in the molding process.

- Q: Can aluminum sheets be used for electronic devices?

- Yes, aluminum sheets can be used for electronic devices. Aluminum is a widely used material in the electronics industry due to its excellent conductivity, low weight, and high durability. It is commonly used for various applications such as housing for electronic components, heat sinks, and electrical connectors. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of electronic devices. Additionally, aluminum is a cost-effective material, making it an attractive choice for manufacturers in the electronics industry.

Send your message to us

Aluminum Insulation Sheets - PVC Aluminium Foil Laminating Extruder PE Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords