Protection platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

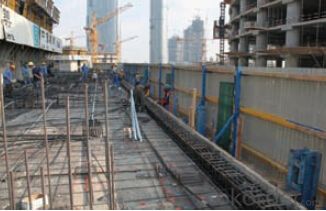

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: How does steel formwork contribute to the sustainability of a project?

- There are several ways in which steel formwork supports the sustainability of a project. Firstly, steel is an incredibly durable material that can withstand the challenges of construction and repeated use. This means that steel formwork can be reused multiple times, reducing the need for new formwork to be manufactured for each project. By minimizing the demand for new materials, steel formwork contributes to the conservation of natural resources and the reduction of the environmental impact associated with extracting, producing, and transporting construction materials. Furthermore, steel formwork offers exceptional dimensional stability, ensuring precision and accuracy during construction. This reduces the chances of errors and rework, leading to a more efficient use of resources such as time, labor, and materials. Additionally, the use of steel formwork results in smooth and high-quality finishes, minimizing the need for additional surface treatments or finishes that can be resource-intensive and contribute to waste generation. Moreover, steel formwork can be easily dismantled and recycled at the end of its lifespan. The steel can be melted down and repurposed for other construction projects, diverting waste from landfills and reducing the demand for newly produced steel. This approach aligns with the principles of a circular economy and helps to decrease the carbon footprint of the construction industry. Lastly, steel formwork enhances safety on construction sites. Its strength and stability minimize the risk of accidents and structural failures, providing protection to workers and the surrounding environment. By promoting a safe working environment, steel formwork contributes to the overall sustainability of a project by preventing injuries, reducing medical costs, and minimizing the negative social and economic impacts associated with accidents. In conclusion, steel formwork supports project sustainability through its durability, reusability, dimensional stability, recyclability, and safety advantages. By reducing the need for new materials, minimizing waste generation, and enhancing construction efficiency, steel formwork helps to conserve resources, mitigate environmental impacts, and foster a more sustainable construction industry.

- Q: What are the different types of safety systems used with steel formwork?

- Steel formwork commonly utilizes various safety systems to ensure worker safety and prevent accidents on construction sites. Some frequently employed safety systems for steel formwork comprise: 1. Guardrails: These are often positioned along the edges of the formwork to avert workers from slipping or falling. Constructed from steel or aluminum, they possess the capacity to withstand a specific amount of force. 2. Safety harnesses: Workers wear safety harnesses, which are fastened to a secure anchor point to prevent falls. These harnesses are typically adjustable to accommodate different body sizes and are crafted from robust, enduring materials. 3. Toe boards: Positioned at the bottom of the formwork, toe boards prevent the dislodgement of tools, materials, or debris from the structure. Usually made of plywood or steel, these boards are firmly affixed to the formwork. 4. Safety nets: Installed beneath the formwork, safety nets are capable of catching falling objects or workers in the event of an accident. Comprised of sturdy, flexible materials, they possess the ability to absorb the impact of a fall. 5. Ladders and stairs: Employed to facilitate secure access to and from the formwork, ladders and stairs are typically constructed from steel or aluminum, ensuring stability and durability. 6. Warning signs and barricades: Warning signs and barricades operate as cautionary measures, alerting workers and visitors to potential hazards and restricted areas. These items are usually manufactured using durable materials and are brightly colored for enhanced visibility. 7. Personal protective equipment (PPE): PPE, including hard hats, safety glasses, and steel-toed boots, is a vital safety system employed in conjunction with steel formwork. These protective measures are designed to safeguard workers against head injuries, eye injuries, and foot injuries. It is important to acknowledge that the selection of specific safety systems for steel formwork may vary depending on project requirements and regulations. Construction companies and workers must meticulously adhere to all safety guidelines and regulations to establish a secure working environment.

- Q: How does steel formwork affect the quality of the concrete finish?

- The quality of the concrete finish can be significantly influenced by steel formwork. To start with, steel formwork offers a rigid and stable structure that guarantees accurate and uniform pouring and curing of the concrete. This helps maintain the desired shape, dimensions, and alignment of the concrete structure, resulting in a polished and consistent finish. Moreover, steel formwork provides a superior surface finish when compared to other types of formwork, such as wood or plastic. The smooth and non-absorbent properties of steel reduce the chances of surface imperfections like air bubbles, honeycombing, or formwork marks, which can negatively impact the appearance and durability of the concrete finish. Additionally, steel formwork displays exceptional resistance to moisture and chemical reactions that may occur during the concrete setting and curing process. This minimizes the risk of efflorescence, staining, or discoloration, ensuring a visually appealing and attractive concrete finish. Furthermore, the use of steel formwork enables better precision and control over the concrete pouring procedure. The tight joints and accurate alignment of steel formwork prevent the leakage of excess water or cement paste, resulting in a denser and more long-lasting concrete surface. Consequently, this enhances the strength, durability, and lifespan of the final concrete structure. In summary, steel formwork plays a vital role in guaranteeing the quality of the concrete finish by offering stability, precision, and a smooth surface. Its ability to minimize surface imperfections, resist moisture and chemical reactions, and enhance the overall strength and durability of the concrete make it an optimal choice for achieving high-quality concrete finishes.

- Q: How does steel formwork affect the overall construction site noise pollution?

- The overall construction site noise pollution can be significantly reduced by steel formwork. Steel formwork offers better acoustic insulation properties compared to traditional wooden formwork. The sound waves are absorbed and dampened by the rigid and dense nature of steel materials, resulting in minimized noise propagation. This is particularly advantageous in densely populated areas or construction sites near residential or commercial areas. In addition, steel formwork is commonly prefabricated, meaning it is manufactured off-site and then assembled on-site. This process reduces construction noise by requiring fewer on-site activities and decreasing the need for cutting, drilling, and hammering, which are major sources of noise pollution. Moreover, the use of steel formwork can lead to faster construction times, resulting in shorter exposure to noise for neighboring communities. Furthermore, steel formwork is more durable and long-lasting than wooden formwork, allowing it to be reused multiple times. This reusability reduces the frequency of formwork installation and dismantling, further decreasing noise pollution generated during the construction process. Overall, the utilization of steel formwork in construction can greatly contribute to the minimization of noise pollution at the construction site. The superior acoustic insulation properties, reduced on-site activities, and longer lifespan all collaborate to create a quieter and more environmentally friendly construction environment.

- Q: Can steel formwork be used for both residential and infrastructure projects?

- Yes, steel formwork can be used for both residential and infrastructure projects. Steel formwork offers numerous advantages such as high strength, durability, and reusability, making it suitable for a wide range of construction applications. In residential projects, steel formwork can be utilized for building foundations, walls, slabs, and columns, providing a robust and efficient solution. Similarly, in infrastructure projects, steel formwork can be employed for constructing bridges, tunnels, highways, and other large-scale structures. Its versatility allows for customization to meet specific project requirements and can withstand heavy loads and adverse weather conditions. Furthermore, steel formwork's ability to be easily assembled, disassembled, and reused makes it a cost-effective option for both types of projects. Overall, steel formwork is a highly adaptable and practical choice for various construction purposes, making it suitable for both residential and infrastructure projects.

- Q: How does steel formwork contribute to improved construction site access?

- Steel formwork contributes to improved construction site access by providing a strong and durable structure that allows for easy and safe movement of workers, equipment, and materials. Its robustness ensures that it can withstand heavy loads and constant use, minimizing the risk of accidents or collapses. Additionally, steel formwork can be easily assembled and disassembled, allowing for efficient and quick access to different areas of the construction site. Its versatility also enables the creation of customized shapes and sizes, adapting to the specific needs of each project and ensuring smooth and unrestricted access throughout the construction process.

- Q: Can steel formwork be used for retaining walls?

- Retaining walls can indeed utilize steel formwork. The popularity of steel formwork for retaining walls stems from its robustness and resilience. It effectively bolsters and stabilizes the concrete throughout the construction phase. The steel formwork's ability to withstand the immense pressure exerted by both the concrete and the soil behind the retaining wall guarantees the structural integrity of the wall. Moreover, the versatility of steel formwork enables the creation of diverse retaining wall designs, as it can adapt to different shapes and sizes. Ultimately, steel formwork proves to be a dependable and efficient choice for retaining walls, ensuring durability and ease of construction.

- Q: How does steel formwork compare to wooden formwork?

- Steel formwork is generally considered to be more durable and long-lasting compared to wooden formwork. It offers greater strength, stability, and resistance to wear and tear, making it suitable for repetitive use in construction projects. Steel formwork also provides better dimensional accuracy and allows for faster assembly and disassembly, thereby increasing overall productivity. However, steel formwork can be more expensive upfront and may require specialized equipment for handling and installation. On the other hand, wooden formwork is typically cheaper, easier to handle, and better suited for small-scale projects or temporary structures. It ultimately depends on the specific requirements of the construction project and the desired balance between cost-effectiveness and longevity.

- Q: How does steel formwork affect the overall thermal performance of the building?

- Steel formwork does not directly affect the overall thermal performance of the building as it is primarily used in the construction process for shaping and supporting concrete structures. However, if steel formwork is not properly insulated or if there are gaps between the formwork and the concrete, it can contribute to thermal bridging, which can negatively impact the building's energy efficiency.

- Q: How does steel formwork affect the construction timeline?

- Steel formwork can have a significant impact on the construction timeline in both positive and negative ways. One of the main advantages of using steel formwork is its durability and strength. Unlike traditional wooden formwork, steel formwork can withstand multiple uses without losing its structural integrity. This means that it can be reused many times, reducing the time and effort required to set up formwork for subsequent construction phases. Additionally, steel formwork allows for faster assembly and disassembly, which can help to expedite construction timelines. Furthermore, steel formwork provides a high level of accuracy and consistency in shaping concrete structures. The precise dimensions and smooth finish achieved with steel formwork ensure that the construction process proceeds smoothly without any delays caused by rework or adjustments. This can lead to faster completion of construction projects. On the other hand, steel formwork can also introduce certain challenges that may affect the construction timeline. Firstly, steel formwork is generally heavier and requires more effort to transport and handle compared to other types of formwork. This may slow down the overall construction process, especially if there are limitations in terms of available equipment or labor. Additionally, steel formwork may require additional time for installation and dismantling compared to other formwork systems. The complexity of steel formwork systems and the need for skilled workers to handle them can result in a longer setup and removal time. This can impact the overall construction timeline, particularly when tight deadlines need to be met. In conclusion, steel formwork can have both positive and negative effects on the construction timeline. Its durability, reusability, and accuracy can help expedite the construction process. However, the weight and complexity of steel formwork may introduce additional challenges that can potentially slow down the construction timeline.

Send your message to us

Protection platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords