Propex Polypropylene Filament Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

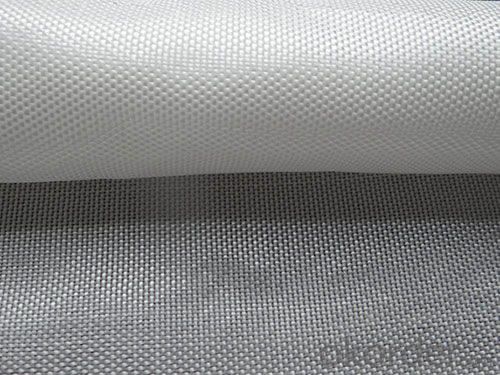

Polypropylene Woven Geotextile

Polypropylene Woven Geotextile Introduction

Woven Geotextile is made of high tenacity and high molecular weight polyester yarns. Wear-resisting, bursting resistant and high tensile strength, also provide different strength at low elongation.

Polypropylene Woven Geotextile Application

Woven geotextile can be applied in soil stabilization, embankment, reinforced wall and slope, sidewalk paver, coastal and riverbank revetments, landfill separators and capping, etc.

Polypropylene Woven Geotextile Advantage

-High tensile strength

-Wear resistant

-Burst resistant

-Easy carry and easy application

Polypropylene Woven Geotextile Specifications

Tensile strength(kN/m) | 100/50 | 200/50 | 400/50 | 600/50 | 800/50 | 1000/50 | 60/60 | 100/100 | 120/120 | 200/200 | 220/220 |

MD Values | 100 | 200 | 400 | 600 | 800 | 1000 | 60 | 100 | 120 | 200 | 220 |

CMD Values | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 100 | 120 | 200 | 220 |

Polypropylene Woven Geotextile photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Geotextile testing standards

- Staple stitch filament piercing filament woven weaving

- Q: How do geotextiles improve the performance of geocells?

- Geotextiles improve the performance of geocells by providing additional reinforcement and stability to the structure. They act as a barrier against soil erosion and help distribute loads evenly, increasing the overall strength and durability of the geocell system. Additionally, geotextiles prevent the mixing of different soil layers, enhancing filtration and drainage capabilities.

- Q: How do geotextiles help in preventing soil contamination from chemicals?

- Geotextiles help prevent soil contamination from chemicals by acting as a physical barrier between the contaminated soil and the surrounding environment. These synthetic materials are placed in soil to serve as a protective layer, preventing the migration of chemicals and pollutants. Geotextiles also aid in filtration, allowing water to flow through while trapping and retaining the harmful substances, minimizing their potential impact on the soil and groundwater.

- Q: What are the factors to consider when maintaining geotextiles?

- When maintaining geotextiles, there are several factors to consider. Firstly, it is important to regularly inspect the geotextiles for any signs of damage or wear. This includes checking for tears, holes, or fraying, as well as monitoring the overall condition of the material. Secondly, it is crucial to properly clean the geotextiles to prevent the buildup of dirt, debris, or organic matter that can compromise their effectiveness. This may involve using appropriate cleaning methods such as gentle washing or vacuuming. Additionally, considering the environmental and weather conditions in the specific location where the geotextiles are installed is essential. Extreme temperatures, UV exposure, and moisture levels can impact the durability and longevity of the material, so appropriate protective measures should be taken to mitigate these factors. Lastly, regular maintenance should include reassessing the performance of the geotextiles and their compatibility with the intended application. This may involve consulting with experts or conducting periodic testing to ensure that the geotextiles continue to meet the required standards and objectives. Overall, diligent inspection, cleaning, protection, and evaluation are key factors to consider when maintaining geotextiles.

- Q: Can geotextiles be recycled?

- Yes, geotextiles can be recycled. They are typically made from synthetic materials such as polypropylene or polyester, which can be melted down and reused to create new geotextile products. Recycling geotextiles helps reduce waste and promotes sustainability in the construction and environmental industries.

- Q: Geotextile GB and Dahua What is the difference between looking at almost ah

- GB is the current national industry standards, Dahua is from the raw materials to distinguish, Huazhi geotextile material manufacturers

- Q: What is the size of the filament geotextile? What are the characteristics of the application?

- What is the size of the filament geotextile? What are the characteristics of the application?

- Q: Can geotextiles be used in underground construction projects?

- Yes, geotextiles can be used in underground construction projects. Geotextiles provide various benefits such as soil stabilization, erosion control, filtration, and drainage, making them suitable for use in underground applications like tunnels, retaining walls, and underground drainage systems. They help improve the overall performance and longevity of the underground structures.

- Q: Are geotextiles suitable for use in dam construction?

- Yes, geotextiles are suitable for use in dam construction. Geotextiles provide reinforcement, filtration, and separation functions, which are essential for enhancing the stability and performance of dams. They help control soil erosion, increase drainage efficiency, and improve overall dam durability.

- Q: Can geotextiles be used in underground pipe installation?

- Yes, geotextiles can be used in underground pipe installation. Geotextiles are often used as a separation and filtration layer between the soil and the pipe to prevent soil intrusion and ensure proper drainage. They help enhance the performance and longevity of underground pipes by providing stability and preventing clogging.

Send your message to us

Propex Polypropylene Filament Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords