Professional Titanium Dioxide Used for Masterbatch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 140000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

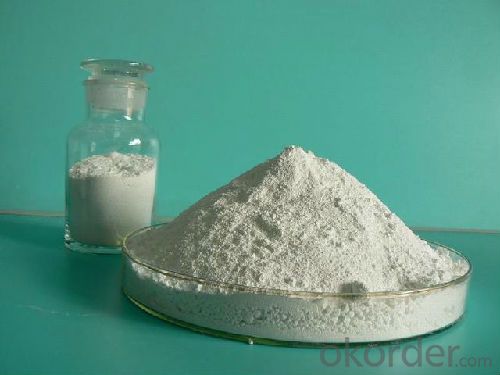

Titanium Dioxide Used for Masterbatch Professional Supplier in China

1.Maily used on plastics,rubber

2.Manufacture

3.Rutile and anatase

4.High quailty,good price

coatings, printing ink, rubber, glass, leather, cosmetics, soaps, plastic and paper making etc

Chemical substances | TiO2/ Rutile Type (R type) |

Appearance | white powder |

Packing | 25kg woven bag, 1000kg sack |

Main features | high purity, high purity, good whiteness, strong hiding power, low abrasion to processing equipments. |

Range of application |

FOR PAINT ,COATING INK ETC.. |

Item | R-908 |

TiO2 Content(%) | 94 |

Rutile content (%) | 99 |

Surface Treatment chemicals | Alumina,Zirconium |

The disposal of organic compounds | Have |

pH Value | 8.0-9.0 |

Density(g/cm3) | 4.05 |

105°C Moisture % | 0.3 |

Particle Size micron | 0.3 |

Oil Absorption (g/100g) max | 20 |

Resistivity (Ω-m) | 150 |

CIE L* | 98.5 |

b* | 1.8 |

Tint-reducing power (Reynold’snumber) | 1900 |

Pb.As.Hg.Cr6+heavy metal element | 10 |

PBB,PBDE | No |

Exterior&interior durability | excellent |

ISO591-1:2000 | R2 |

ASTM D476:00 | II,III,IV |

- Q: i have a plain bird house, should i paint it? or leave

- Well the straight birds can care less, but the gay ones may want a nice pastel color to come home too.

- Q: What is the difference between phthalocyanine blue B and phthalocyanine blue BGS? Can the pigment be soluble in water?

- Dye and pigment, it is soluble in water, alcohol, oil or other solvents and other liquids in the color of the material. Dye solution can penetrate the wood, and wood composition (cellulose, lignin and hemicellulose) complex physical and chemical reactions, can make the wood color and not to blur the texture of wood, can make wood dyed and fast s color

- Q: Solid wood crib is a good paint, or no paint is good

- Baoshan paint paint advice: very tangled, buy cribs, colleagues and friends say, to buy lacquered wood cots, because there is no taste, more environmentally friendly. Internet search, but found very expert advice, the purchase of environmentally friendly cots cots, cows exported export, are needed to paint, the EU and other countries are not allowed to import pure lacquered crib. Baoshan paint, say good, healthy home and ultimately!

- Q: What dispersant can disperse the dye?

- Disperse dyes are a class of non-ionic dyes with less water solubility. The earliest for the dyeing of acetate fiber, known as vinegar fiber dyes. With the development of synthetic fibers, nylon, polyester have emerged, especially polyester, because of the whole column with high, low fiber gap, hydrophobic and other characteristics, in a carrier or high temperature, hot melt fiber expansion, the dye can enter Fiber and dye.

- Q: And when it dries you can paint it whatever colours you want

- Some air-dry clay IS white although the most popular brand is terracotta - dull red. You can paint it to your heart's content.

- Q: Home spray latex paint, found the brand, the Internet are found to be VOC-free, small aspects of harm, but no user evaluation of its effect ,,, have not used friends, effects and those big What about the brand? The Mainly and Nippon 5IN1, more happy 5IN1 than, the effect is not different

- Latex paint is mostly environmentally friendly, you can rest assured that the use of the main point is that the harm of paint, and if you want to compare with the Dorothy and the state, then certainly not more than Dulux gold 5 and 1, Many people do not use Nippon Paint, because the manufacturers too much, and too much fake, the price difference is also great

- Q: Use of textile pigments

- I think that textile pigments and I should be used to reconcile the similar methods of propylene, Mali brand of textile paint to use the specified blend of oil color, the import of textile pigments do not have to reconcile the oil, if necessary, add some water. The ratio of oil to pigment is 1: 2.

- Q: Is coated with a type of paint? What are the characteristics? What is the difference with the finish?

- Paint, painted in Chinese tradition as a paint. China's paint industry more authoritative "paint technology" a book is so defined: "paint is a material, this material can be used in different construction techniques coated on the surface of the object, the formation of strong adhesion, with a certain strength, continuous Solid film. Such a film known as the coating, also known as paint film or coating. "Most of the early vegetable oil is not the main raw material, it is called" paint. " Whether the traditional natural materials as raw materials of paint products, or modern development of synthetic chemical products as raw materials, paint products, are organic chemical polymer materials, the formation of the coating is a polymer compound type. In accordance with the classification of modern chemical products, paint is a fine chemical products. Modern coatings are gradually becoming a versatile engineering material, an important industry in the chemical industry.

- Q: It is said that the characteristics of carbon is the color black, but how do I think the color of carbon ink is far less than dye ink so black

- Not enough black put the ink bottle open, dry until only half a bottle when the original use, when the time will be black to the pen plug.

- Q: What is the difference between the copolymer and the polymer?

- A copolymer is composed of two or more monomers

1. Manufacturer Overview

| Location | Langfang City,Hebei Province,China |

| Year Established | 2007 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America, Domestic Market, South America, Western Europe, Mid East |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 5 - 10 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | 1,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Titanium Dioxide,White Carbon Black,Lithopone,Zinc Oxide,Barium Sulphate,Manganese Carbonate |

| Product Price Range | Average |

Send your message to us

Professional Titanium Dioxide Used for Masterbatch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 140000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords