Prime Round Welded Steel Pipe Api 5l Gr. B Used For Oil and Gas Transportation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Prime Round Welded Steel Pipe Api 5l Gr. B Used For Oil and Gas Transportation:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Prime Round Welded Steel Pipe Api 5l Gr. B Used For Oil and Gas Transportation:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Prime Round Welded Steel Pipe Api 5l Gr. B Used For Oil and Gas Transportation Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | He Bei, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery of Prime Round Welded Steel Pipe Api 5l Gr. B Used For Oil and Gas Transportation:

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 30-45days after received 30%TT |

5、FAQ of Prime Round Welded Steel Pipe Api 5l Gr. B Used For Oil and Gas Transportation:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

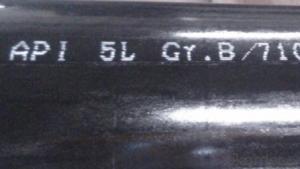

6、Prime Round Welded Steel Pipe Api 5l Gr. B Used For Oil and Gas Transportation Images:

- Q: Can steel pipes be used for fire sprinkler systems?

- Yes, steel pipes can be used for fire sprinkler systems. Steel pipes are commonly used in fire sprinkler systems due to their durability, high heat resistance, and ability to withstand high water pressure. They are also cost-effective and widely available, making them a popular choice for such systems.

- Q: How are steel pipes used in the aerospace industry?

- Steel pipes are widely used in the aerospace industry for various applications. One of the primary uses of steel pipes in aerospace is for the construction of aircraft frames, where they provide the necessary strength and structural integrity. Steel pipes are often used in the fuselage, wings, and landing gear of airplanes, as well as in rocket launch vehicles and space shuttles. Steel pipes are favored in the aerospace industry due to their exceptional strength-to-weight ratio. They are lightweight yet incredibly strong, allowing for the construction of durable and reliable aerospace structures. This is particularly crucial in the aerospace industry, where weight reduction is a significant concern to enhance fuel efficiency and overall performance. Additionally, steel pipes are also utilized for the transportation of fluids and gases within aircraft systems. They are commonly used in the aircraft's hydraulic and fuel systems, carrying crucial fluids such as hydraulic fluid, fuel, and coolant. Steel pipes ensure the safe and efficient flow of these fluids throughout the aircraft, contributing to its proper functioning and performance. Furthermore, steel pipes are employed in the aerospace industry for heat transfer purposes. They are used as part of the aircraft's cooling systems, helping to dissipate heat generated by engines, electrical components, and other systems. Steel pipes are known for their excellent thermal conductivity, making them an ideal choice for transferring heat away from critical areas and preventing overheating. In summary, steel pipes play a vital role in the aerospace industry. They are used in aircraft construction for their strength and structural integrity, as well as for fluid and gas transportation and heat transfer. The use of steel pipes in the aerospace industry ensures the safety, efficiency, and reliability of aerospace structures and systems.

- Q: 304 stainless steel tube with the diameter of 25*2-3 is what mean

- This is according to the "water drawing standards" (GBT50106-2001) in 2.4.2-2 seamless steel pipe, welded steel pipe (straight or spiral seam), brass, stainless steel pipe, pipe diameter should be D diameter * thickness representation (such as D108 * 4 and D159 * 4.5); and the provisions of the habit of acting D with seamless pipe diameter.

- Q: What are the alternatives to steel pipes for various applications?

- Some alternatives to steel pipes for various applications include PVC (polyvinyl chloride) pipes, copper pipes, aluminum pipes, and fiberglass pipes. Each alternative has its own advantages and disadvantages, such as cost, durability, and resistance to corrosion, which make them suitable for specific applications.

- Q: Can steel pipes be used for underground cable protection?

- Yes, steel pipes can be used for underground cable protection. Steel pipes offer durability, strength, and corrosion resistance, making them suitable for protecting cables from external factors such as moisture, chemicals, and physical damage. Additionally, steel pipes can be coated or galvanized to provide further protection against rust and corrosion.

- Q: What's the gate number of the precision steel pipe?

- This kind of steel tube and ordinary hot-rolled seamless steel pipe and cold drawn seamless steel tube in the outer surface is different from the outer surface, and the diameter of the smooth finish of precision steel tube, stainless steel color and the same, inside and outside surface due to manufacturing reasons with a layer of oil.

- Q: Why seamless steel pipe called seamless steel pipe?

- Seamless steel pipe is a hollow section, without the joint round, square, rectangular steel. Seamless steel tubes are made of ingots or billets made by piercing and are then made by hot rolling, cold rolling or cold casting. Seamless steel pipe with a hollow section, as pipe conveying fluid, compared withsteel and roundsteelinsolid, flexural torsional strength in the same time, the weight is light, is a kind of economic section steel, widely used in the manufacture of structural parts and mechanical parts, such as the oil pipe, automobile transmission shaft, bike frame and construction using steel scaffolding.

- Q: What are the safety measures to be followed while working with steel pipes?

- When working with steel pipes, it is important to follow several safety measures to ensure the well-being of workers and prevent accidents. Some of the key safety measures include: 1. Personal Protective Equipment (PPE): Workers should always wear appropriate PPE, including safety glasses, steel-toed boots, gloves, and hard hats to protect themselves from potential hazards. 2. Proper Lifting Techniques: Steel pipes can be heavy, so workers should use proper lifting techniques, such as bending their knees and using their leg muscles, to prevent strain or injury to their back. 3. Secure Storage and Handling: Steel pipes should be stored in a secure and organized manner to prevent them from falling or causing any hazards. Workers should also use appropriate lifting equipment, such as cranes or forklifts, to handle heavy steel pipes safely. 4. Inspect Pipes for Defects: Before working with steel pipes, they should be inspected for any defects, such as cracks or corrosion, that could compromise their structural integrity. Damaged pipes should be replaced to avoid potential accidents. 5. Proper Welding and Cutting Techniques: When welding or cutting steel pipes, workers should follow proper techniques and use appropriate safety equipment, such as welding masks and fire-resistant clothing, to prevent burns, fires, or explosions. 6. Fall Protection: When working at heights or on elevated platforms, workers should use fall protection equipment, such as harnesses and safety nets, to prevent falls and injuries. 7. Adequate Ventilation: In enclosed spaces where welding or cutting activities take place, proper ventilation should be ensured to prevent the accumulation of harmful fumes or gases. 8. Fire Prevention: Steel pipes can be flammable, especially when cutting or welding. Therefore, it is crucial to have fire prevention measures in place, such as fire extinguishers and fire blankets, and to follow proper fire safety protocols. By adhering to these safety measures, workers can minimize the risks associated with working with steel pipes and create a safer working environment.

- Q: What industries typically use steel pipes?

- Industries such as construction, oil and gas, water treatment, automotive, and manufacturing typically use steel pipes.

- Q: What are the different types of coatings used on steel pipes?

- There are several types of coatings that are commonly used on steel pipes to enhance their durability and protect them from corrosion. Some of the most common types of coatings include: 1. Fusion-Bonded Epoxy (FBE) Coating: This coating is applied to the steel pipe through a process of heating and melting the epoxy powder, which then fuses to the surface. FBE coatings provide excellent corrosion resistance and are commonly used in water pipelines and oil and gas industries. 2. Polyethylene (PE) Coating: PE coatings are applied to steel pipes using a similar process as FBE coatings. PE coatings provide a protective layer that is resistant to moisture, chemicals, and abrasion. They are commonly used in gas pipelines and underground water pipelines. 3. Polypropylene (PP) Coating: PP coatings are similar to PE coatings in terms of their application process and protective qualities. However, PP coatings offer enhanced resistance to higher temperatures, making them suitable for applications such as chemical processing plants and refineries. 4. Concrete Weight Coating (CWC): CWC is a special coating that involves applying a layer of concrete to the steel pipe. This coating provides additional weight to the pipe, making it more stable and resistant to buoyancy in underwater or submerged applications. 5. Zinc Coating: Zinc coatings, such as hot-dip galvanizing, involve immersing the steel pipe in a bath of molten zinc. This process creates a protective layer of zinc on the surface of the pipe, offering excellent corrosion resistance. Zinc coatings are commonly used in outdoor applications, such as fencing, guardrails, and water pipelines. 6. Bituminous Coating: Bituminous coatings involve applying a layer of bitumen or asphalt to the steel pipe. This coating provides excellent resistance to water and chemicals, making it suitable for underground pipelines and structures. These are just a few examples of the different types of coatings used on steel pipes. The choice of coating depends on factors such as the intended application, environmental conditions, and the level of corrosion resistance required.

Send your message to us

Prime Round Welded Steel Pipe Api 5l Gr. B Used For Oil and Gas Transportation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords