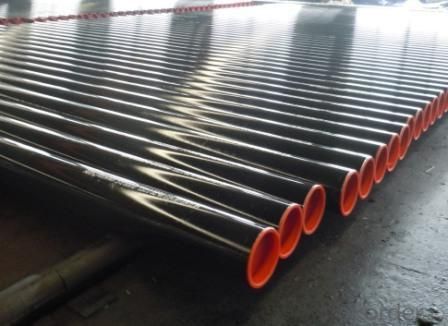

ERW STEEL PIPE API 5L

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1)Outside Diameter: 10.3mm--914.4mm

2)Wall Thickness: 0.5~59.54mm

3)Length: Random 1~12m or fixed 6

4)Material quality: ASTM A106 / A53/A210, API 5L,API 5CT,DIN, EN, GB/T8162 / 8163, etc

5)Packing:Hexangular packing in bundles

6)Export: Europe, North America, the Middle East, Africa, Asia and other countries and regions, well received by consumers!

Product Name: | ERW pipe | |

Size | OD | 1/8” -24” (10.3mm-914.4mm) |

Wall Thickness | 0.5mm-59.54mm SCH30,SCH40,STD,XS,SCH80,SCH,XXS | |

Length | 1m-12m | |

Steel material | Q195,Q215,Q235,Q345,STL400,ST37-2,16Mn,X42,X52,X80,E235, Grade B, SS330,SPHC, S185,SS400,S235JR,ST52,STK500 | |

Standard | BS1387-1985,ASTM A53,ASTM A106,GB/T3091-93-2008,EN10129,JIS. | |

Usage | Used For irrigation,Structure, Accessorize And Construction | |

Ends | 1) Plain 2) Beveled 3) Threaded with Coupling & cap | |

Surface Treatment | 1) Bared 2) Black Painted (varnish coating) 3) Galvanized 4) With Oiled | |

Technique | Electronic Resistance Welded (ERW ) Electronic Fusion Welded (EFW) Double Submerged Arc Welded (DSAW) | |

Welded Line Type | Longitudinal | |

Inspection | With Hydraulic Test, Eddy Current , Infrared Test | |

Package | In Bundle with water-proof package | |

Delivery | 1) Container 2) Bulk carrier | |

Port of Shipment | Xingang Port,Tianjin, China | |

Date of Delivery | 15 days after contract | |

Payment | L/C at sight or 30% T/T | |

Others | Fitting as coupler and flange also can be supplied. | |

- Q: What are the properties of steel that make it suitable for pipe manufacturing?

- Due to its unique properties, steel is highly favored as a material for manufacturing pipes. The exceptional strength and durability of steel allow it to withstand high pressure and extreme temperatures, ensuring the safe transportation of fluids and gases over long distances without the risk of leakage or breakage. Another significant advantage of steel is its resistance to corrosion. Unlike other materials that can degrade when exposed to corrosive substances such as water, chemicals, and gases, steel remains highly resistant to corrosion. This quality makes steel pipes long-lasting and reliable. Furthermore, steel is a versatile material that allows for the production of pipes in various sizes and shapes. This flexibility enables customization to meet specific project requirements, making steel pipes suitable for a wide range of applications, including water supply, oil and gas transmission, sewage systems, and structural support. Moreover, steel possesses excellent thermal conductivity, which is crucial for applications involving the transportation of hot or cold fluids. Steel pipes efficiently transfer heat, ensuring minimal energy loss during the process. Additionally, steel is an environmentally friendly option for pipe manufacturing due to its recyclability. Steel pipes can be recycled and reused, reducing the demand for new raw materials and minimizing waste generation. In conclusion, the properties of strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability make steel the ideal choice for pipe manufacturing. These properties guarantee the reliability, efficiency, and longevity of steel pipes in various industries and applications.

- Q: Can steel pipes be used for structural supports?

- Yes, steel pipes can be effectively used as structural supports due to their high strength, durability, and ability to withstand heavy loads.

- Q: How are steel pipes used in the mining and mineral processing industry?

- Steel pipes are commonly used in the mining and mineral processing industry for various purposes such as transporting liquids, gases, and slurries, as well as providing structural support for mining infrastructure. These pipes are highly durable and resistant to corrosion, making them suitable for harsh and demanding environments. They are used for tasks such as transporting water for mining operations, carrying tailings and waste materials, and conveying mining chemicals. Additionally, steel pipes are utilized in the construction of mine shafts, tunnels, and processing plants, providing a strong and reliable framework for mining operations.

- Q: What is a valve and how is it used in steel pipes?

- A valve is a device used to control the flow of fluid or gas within a system. In steel pipes, valves are used to regulate and control the flow of liquids or gases by opening, closing, or partially obstructing the passage within the pipe. They are essential for redirecting or stopping the flow, ensuring the safe and efficient operation of the steel pipe system.

- Q: What are the different types of gaskets used with steel pipes?

- There are several types of gaskets used with steel pipes, including spiral wound gaskets, ring joint gaskets, and non-metallic gaskets. These gaskets are used to create a tight seal between pipe flanges, preventing leakage of fluids or gases.

- Q: What are the different joining methods for steel pipes?

- There are several joining methods for steel pipes, including welding, threaded connections, flanged connections, and mechanical couplings. Welding involves melting the ends of the pipes and fusing them together using heat. Threaded connections involve screwing the pipes together using threaded ends. Flanged connections use flanges that are bolted together to connect the pipes. Mechanical couplings use a variety of methods such as compression fittings or grooved couplings to connect the pipes without welding or threading.

- Q: Can steel pipes be used for underground water treatment systems?

- Yes, steel pipes can be used for underground water treatment systems. Steel pipes are commonly used in underground applications due to their durability, strength, and resistance to corrosion. They provide a reliable and long-lasting solution for transporting water in underground water treatment systems.

- Q: What are the environmental impacts of steel pipe production and disposal?

- The production and disposal of steel pipes have significant environmental impacts. Firstly, the production of steel pipes requires the extraction of raw materials such as iron ore, coal, and limestone. This extraction process leads to habitat destruction, deforestation, and soil erosion. Additionally, mining and processing these materials require a considerable amount of energy, often derived from fossil fuels, contributing to greenhouse gas emissions and air pollution. The manufacturing process itself involves various stages, including melting, casting, rolling, and coating, all of which require substantial energy inputs and emit significant amounts of carbon dioxide and other greenhouse gases. Moreover, the production of steel pipes involves the use of chemicals and additives that can be harmful to the environment if not managed properly. Furthermore, during the disposal of steel pipes, if not recycled or properly managed, they can end up in landfills, contributing to waste accumulation and taking up valuable space. Steel is generally non-biodegradable and can take hundreds of years to decompose. When steel pipes are dumped in landfills, they can release toxic substances and heavy metals, which can contaminate soil and groundwater. However, it is important to note that steel pipes are highly recyclable, and recycling them significantly reduces the environmental impact. Recycling steel pipes helps conserve natural resources, reduces energy consumption, and lowers greenhouse gas emissions. Additionally, using recycled steel in the production of new pipes requires less energy and results in fewer emissions compared to using virgin materials. To minimize the environmental impacts of steel pipe production and disposal, it is crucial to promote sustainable practices throughout the entire lifecycle of the product. This includes reducing energy consumption, utilizing renewable energy sources, implementing proper waste management strategies, and encouraging the recycling and reuse of steel pipes.

- Q: What is the difference between API 5L and ASTM A106 steel pipes?

- API 5L and ASTM A106 are two commonly used specifications for seamless carbon steel pipe. While both specifications cover similar materials, they have different requirements for chemical composition, manufacturing processes, mechanical properties, and testing. API 5L is a specification created by the American Petroleum Institute (API) for line pipe used in oil and gas transportation. It covers seamless and welded steel pipe suitable for use in conveying gas, water, and oil in the natural gas and petroleum industries. API 5L specifies the minimum requirements for the manufacture of two product specification levels (PSL 1 and PSL 2) of seamless and welded steel pipes, with different chemical composition and mechanical properties. On the other hand, ASTM A106 is a specification developed by the American Society for Testing and Materials (ASTM) for seamless carbon steel pipe for high-temperature service. It covers seamless carbon steel pipe for high-temperature service in NPS 1/8" to NPS 48" inclusive, with nominal (average) wall thickness as given in ANSI B36.10. ASTM A106 provides requirements for chemical composition, manufacturing processes, mechanical properties, and testing. One key difference between API 5L and ASTM A106 is the intended use of the pipe. API 5L is specifically designed for transmission of liquid and gas, while ASTM A106 is used for high-temperature service. The chemical composition and mechanical properties of the steel may also vary between the two specifications, depending on the grade and type of steel being used. In summary, while both API 5L and ASTM A106 are widely used specifications for carbon steel pipe, they have distinct differences in terms of their intended use, chemical composition, manufacturing processes, mechanical properties, and testing requirements. It is important to carefully consider these factors when selecting the appropriate steel pipe for a specific application.

- Q: How are steel pipes used in the construction of power plants?

- Steel pipes are widely used in the construction of power plants as they serve multiple purposes. They are primarily used for transporting various fluids, such as water, steam, and fuel, throughout the plant. Steel pipes are also used for the construction of boilers, heat exchangers, and condensers, which are essential components in power generation. Additionally, steel pipes are utilized in the construction of cooling systems, air ventilation systems, and structural supports within power plants. Overall, steel pipes are crucial for the efficient and reliable operation of power plants.

Send your message to us

ERW STEEL PIPE API 5L

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords