Prime Hot Rolled Carbon Steel Plate_Sheet dimensions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

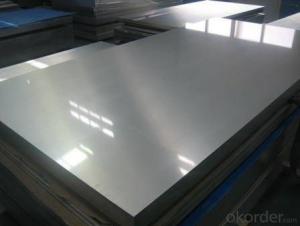

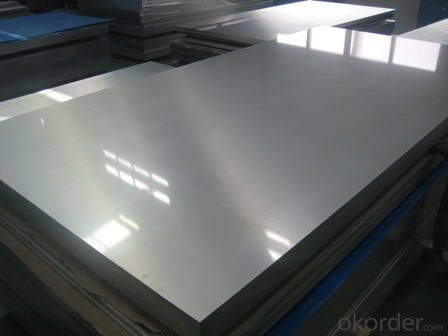

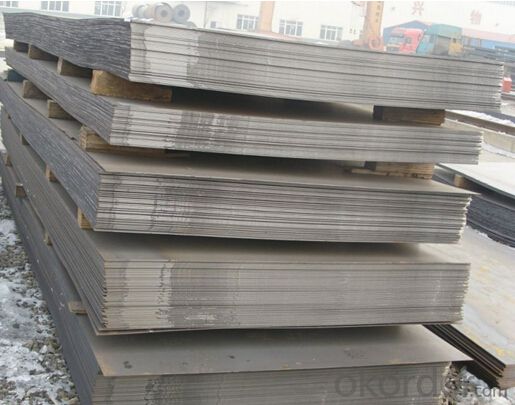

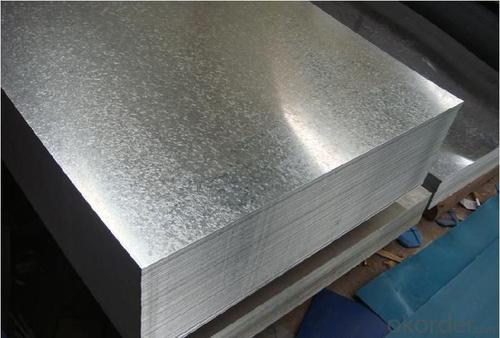

Prime Hot Rolled Carbon Steel Plate_Sheet Dimensions

Thickness:0.6-200mm

Width:1000-4000mm

MOQ: 1 ton

Certificate:ISO,SGS

Specification of Hot Rolled Carbon Steel Plate_Sheet

Commodity | Prime hot rolled carbon steel plate / sheet dimensions |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 SAE1010,SAE1020,SAE1045,Q195,Q235,Q345,SS400,ASTM A36,E235B mild steel plate |

Usage | the mild steel plate will used in home appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of the Hot Rolled Carbon Steel Plate_Sheet Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of the Hot Rolled Carbon Steel Plate_Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How is special steel used in the production of hydraulic components?

- Special steel is used in the production of hydraulic components due to its high strength, durability, and corrosion resistance properties. It allows for the manufacturing of hydraulic parts that can withstand high pressure, extreme temperatures, and harsh operating conditions. The use of special steel ensures the longevity and reliability of hydraulic components, making them suitable for various industries such as automotive, aerospace, and manufacturing.

- Q: How is special steel used in the oil and gas industry?

- Special steel is used extensively in the oil and gas industry due to its unique properties and high strength. It is specifically designed to withstand harsh environments, corrosion, and extreme temperatures. Special steel is used in various applications such as drilling equipment, pipelines, storage tanks, and valves, ensuring reliability and safety in the extraction, transportation, and processing of oil and gas.

- Q: How does special steel compare to other materials, such as aluminum or titanium?

- Special steel is a highly versatile material that offers several advantages over other materials like aluminum or titanium. It is known for its superior strength, durability, and resistance to wear and corrosion. Compared to aluminum, special steel is typically stronger and more rigid, making it ideal for applications that require high load-bearing capabilities. In comparison to titanium, special steel often possesses similar or even greater strength, at a lower cost. Overall, special steel is highly valued for its outstanding mechanical properties, making it a preferred choice in various industries.

- Q: What are the different methods for improving the magnetic properties of special steel?

- There are several methods for improving the magnetic properties of special steel, including annealing, alloying, and heat treatment. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which helps to refine the grain structure and reduce magnetic losses. Alloying is another method, where specific elements like nickel or cobalt are added to the steel to enhance its magnetic properties. Heat treatment is also commonly used, involving controlled heating and cooling processes to alter the microstructure and improve magnetic performance.

- Q: What are the different methods of surface protection for special steel?

- There are several methods of surface protection for special steel, including galvanizing, painting, powder coating, electroplating, and hot-dip coating. Each method offers different advantages and is suitable for various applications based on factors such as corrosion resistance, durability, aesthetics, and cost-effectiveness.

- Q: What are the different surface treatments for special steel?

- For special steel, there exist various surface treatments that serve distinct purposes and offer unique benefits. Some commonly employed surface treatments include: 1. Galvanization, which entails coating the steel with a layer of zinc, providing exceptional corrosion resistance. Galvanization proves popular for outdoor applications exposed to moisture and harsh environmental conditions. 2. Powder coating, involving the application of a dry powder to the steel surface, which is then heated and cured to form a durable and protective coating. This treatment offers excellent resistance against corrosion, chemicals, and UV rays, making it ideal for automotive parts, appliances, and outdoor furniture. 3. Nitriding, a surface hardening treatment that diffuses nitrogen into the steel surface. Nitriding significantly enhances surface hardness, wear resistance, and fatigue strength. It finds common use in high-performance components like gears, crankshafts, and injection molding screws. 4. Electroplating, where a layer of metal such as chromium, nickel, or gold is deposited onto the steel surface through an electrochemical process. This treatment improves appearance, corrosion resistance, and wear resistance. Electroplating is often employed for decorative purposes or to enhance component performance in various industries. 5. Passivation, a chemical treatment that eliminates iron contaminants from the steel surface, creating a passive oxide layer. This layer acts as a barrier against corrosion, enhancing resistance to rust and other forms of degradation. Passivation is commonly used for stainless steel components in industries like food processing, pharmaceuticals, and medical devices. 6. Carbonitriding, a surface treatment that introduces carbon and nitrogen into the steel surface at high temperatures. This process forms a hardened case, improving wear resistance and fatigue strength. Carbonitriding finds frequent application in high-stress components such as gears, crankshafts, and camshafts. These examples represent just a fraction of the available surface treatments for special steel. The choice of treatment depends on factors like desired properties, application requirements, and budget constraints. Consulting experts or manufacturers is crucial for determining the most suitable surface treatment for specific steel applications.

- Q: What are the main applications of special steel in the medical field?

- Special steel is widely used in the medical field for various applications. One of the main applications is in surgical instruments, where special steel alloys provide excellent strength, durability, and corrosion resistance. These alloys are also used in the production of medical implants, such as artificial joints and bone plates, due to their biocompatibility and ability to withstand the demanding conditions inside the human body. Additionally, special steel is utilized in medical devices like needles, catheters, and dental instruments, ensuring precision, hygiene, and reliability in these critical tools.

- Q: What are the main characteristics of tool steel?

- Tool steel is a type of steel that possesses several key characteristics, including high hardness, wear resistance, toughness, and heat resistance. It is specifically designed to be used in the production of tools and dies, where it needs to withstand intense pressure, abrasion, and high temperatures. Additionally, tool steel has the ability to retain its shape and sharpness even under heavy use, making it highly durable and reliable for various industrial applications.

- Q: What are the requirements for special steel used in textile machinery?

- The requirements for special steel used in textile machinery include high strength and durability, excellent corrosion resistance, good wear resistance, and the ability to withstand high temperatures and pressures. Additionally, the steel should have good machinability and be able to maintain dimensional stability under various operating conditions.

- Q: How does special steel contribute to the manufacturing of springs for automotive applications?

- Special steel plays a crucial role in the manufacturing of springs for automotive applications due to its unique properties and characteristics. Springs are essential components in automobiles as they provide the necessary suspension and shock absorption, ensuring a smooth and comfortable ride. One of the key advantages of special steel in spring manufacturing is its high strength and durability. Springs are subject to constant stress and repetitive loading, and special steel, with its exceptional strength, can withstand these forces without deforming or breaking. This property ensures that the springs can function reliably and maintain their shape and performance over extended periods of use. Additionally, special steel offers excellent fatigue resistance, which is vital for springs in automotive applications. Fatigue occurs when a material weakens and eventually fails after repeated loading and unloading cycles. Special steel is specifically designed to withstand fatigue, allowing the springs to endure the constant pressure and stress without experiencing premature failure. Moreover, special steel provides superior corrosion resistance, which is particularly important for automotive springs. Cars are exposed to various environmental elements, including moisture, road salt, and chemicals, which can lead to corrosion and deterioration of the springs. By using special steel with enhanced corrosion resistance, manufacturers can ensure that the springs have a longer lifespan and maintain their performance even in harsh conditions. Furthermore, special steel offers versatility in terms of its composition and properties. Manufacturers can choose from a wide range of special steel alloys, each with its own unique characteristics, to meet specific requirements. For example, some alloys offer greater elasticity, allowing the springs to flex and absorb shocks more effectively. Others provide higher hardness, enhancing the springs' load-bearing capacity. This flexibility in material selection empowers manufacturers to design and produce springs that are tailored to the specific needs of automotive applications. In conclusion, special steel significantly contributes to the manufacturing of springs for automotive applications by providing high strength, durability, fatigue resistance, corrosion resistance, and versatility. These properties enable the production of reliable, long-lasting springs that ensure optimal suspension, shock absorption, and overall performance in vehicles.

Send your message to us

Prime Hot Rolled Carbon Steel Plate_Sheet dimensions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords