Price of Aluminum Bars - AA1070 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1070 D.C Mill Finished Aluminum Circles used for Cookware Description

AA1070 D.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1070 D.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1070 D.C Mill Finished Aluminum Circles used for Cookware

1)Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

2)Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3)Fine craftsmanship

4)Durable

5)Easy processing

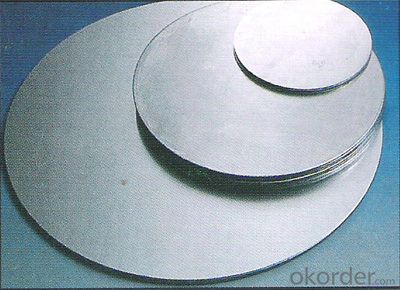

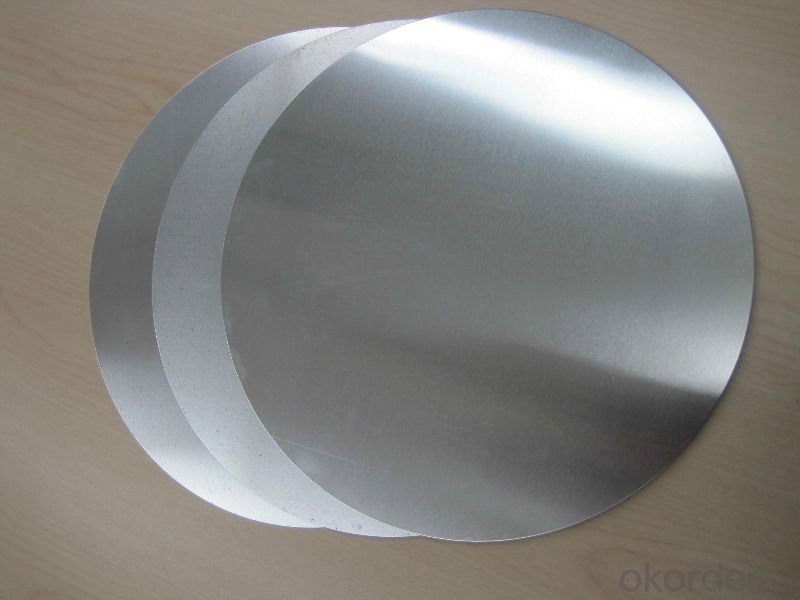

3.AA1070 D.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1070 D.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1070 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1070 D.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

- Q: The cost of buying aluminum bars and aluminum bars is how do we do the accounting entries?

- The subject is contradictory. 1., did you buy the aluminum bar? 2. since the purchase of aluminum rods, purchase costs, of course, you out, please detail

- Q: Can aluminum bars be used as car wheels?

- Aluminum bar also depends on his composition is not A356, and now in addition to forging ingredients are different, basically A356

- Q: What does "T4" mean in the material of aluminum bar?

- 1, aluminum is mostly heat treatment, but because of the application of different occasions, so the heat treatment of the material after the state is divided into T1~T10, a total of ten levels, called the state subdivision level, for different purposes.

- Q: Aluminum stick, 6351-t6? What do you mean?

- 6351 Aluminum Alloy is a kind of high strength 6 series alloy, 6061 alloy high strength ratio, slightly lower than the 6082 alloy, such as 6351-T6 profile minimum tensile strength 295Mpa, extrusion molding is good, 6351 Aluminum Alloy for extrusion structural materials of road transport facilities, materials need high strength gas and oil and water pipelines.

- Q: What material is produced by electrolytic water experiment of aluminum rods of iron rods?

- When the aluminum rod is used as the anode of the power supply, the negative pole of the iron rod is connected with the cathode of the power supply as the cathodeBecause aluminum is a living metal, aluminum will lose electrons as an anodeThe anodic reaction leads to the loss of aluminum to trivalent aluminiumThe cathode react with hydrogen ions to change electrons into hydrogenIf water is to be produced by electrolysis of water, oxygen should be used as anode and the cathode material connected to the negative electrode of the power supply does not matterI hope my answer will be helpful to you

- Q: What's the difference between cast aluminum bars and extruded aluminum bars?

- 1:Charging, melting, melting, stirring, adding waste completely melting, adding waste, melting, and covering agent and deslagging agent, slag, stirring, sampling, furnace analysis, plus Al-Si (Sl-Cu, Cr, Mg, additive) ingot stirring, sampling, analysis, composition adjustment, furnace refining drossing cover, standing for 2, 3, saw material casting4, aluminum rod homogenizing 5, cooling and washing rod (two) extrusion process extrusion process flow:The pressure before, extrusion, stretching and straightening, cutting, trimming and framing finished 1, before 2, extrusion extrusion3 、 stretch straightening4, finished cutting, trimming and framing (three) aging process

- Q: Why use a lightweight aluminum rod as a lead in the magnetic field?

- Thus, the subsequent test error caused by the magnetization of the material can be eliminated.The magnetic field is a powerful effect on the electrified light aluminum rod, and the motor is made of this principle.

- Q: I know that aluminum plate can be punched, aluminum material can be forged and cast, but I do not know what this extrusion means Profiles and god horse? Can I say the next process?.. Thank you

- Aluminum extrusion process, extrusion can be divided into: - straight - interrupted cutting to length of time, profile refers to the Aluminum Alloy profile, its thick wall material section is uniform along its longitudinal length, cross-sectional uniformity, and cross-sectional shape is different from the bar, pipe, sheet or strip products. It can be divided into solid section and hollow section

- Q: there is chip removal problem, aluminum chip bits of drilling chip in the groove into a block, seek expert advice 20The system is emperor Kaine 100T-BProgramming: G74 R2;G74 Z-35 Q4000 F100Kerosene cooling

- Reduce the speed, or increase the speed can be resolved, 200 or 1200, the problem must be solved, you brush kerosene cooling it? If the conditions are not allowed, you can use a plastic bottle to drill a hole in the bottle lid, because when drilling, cutting fluid is best to shoot into, and then brushing the oil is really easy to stick knife

- Q: What are the advantages and disadvantages of aluminum bars for high temperature and low temperature extrusion?

- With the rapid development in recent years, the scientific and technological, as well as the growing demand for industrial economy, aluminum alloy welding structure, welding of aluminum alloy will also be in-depth study.

Send your message to us

Price of Aluminum Bars - AA1070 D.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches