PRESSED WIRE ROPE SLINGS (FIBER CORE)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

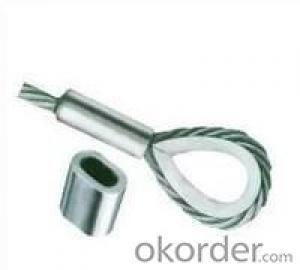

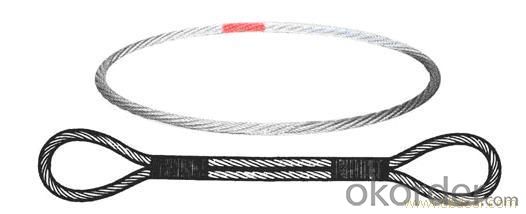

Overview of the pressed wire rope sling

Pressed Steel Wire Rope Sling is made by using the best high quality steel wire rope and produced with the most professional equipments and technics.It is processed by the steel wire rope pressing sleeve machine. The sling is widely used in the field of machinery, metallurgy, construction, shipping, bridge project, gymnasium, oil field, fishing, drilling, colliery and ports etc.

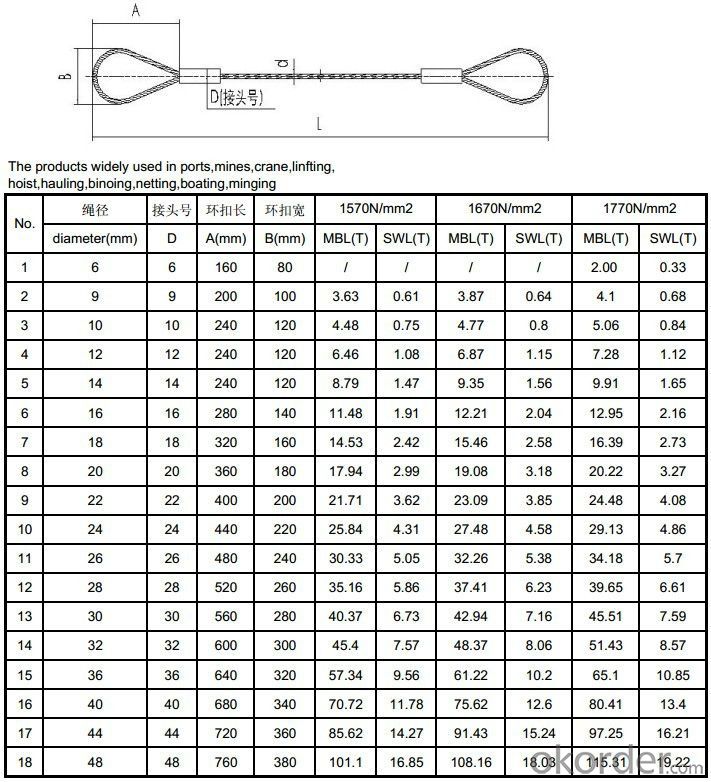

Technical Data

Advantages

1.high strength,

2.light self weight,

3.being steady at work,

4.being not easily broken suddenly and so on

Processing modes

Press the end or both ends to be rings.

It can be combined as sing leg sing ,two-leg sling, tree-leg sling, four-leg sling or more.

How to use

You can choose the wire rope sling made of galvanized steel wire rope to enhance the anti-rust capability.

Besides the abrasion of the outer layer,, it will be broken gradually as the metal fatigue caused by repeated bending when it bypasses the hook and the lifted goods, so the ratio between the hook or the lifted good and the diameter of the steel wire rope decides the service life of the steel wire rope sling.

The pressed wire rope sling is mainly used in transportation which need high strength sling.

Forbidden to stay below the lifted goods or across the goods when working.

FAQ

Q: How’s your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

Picture

- Q: What are the different types of steel sections used in bridges?

- There are several types of steel sections used in bridges, including I-beams, H-beams, box girders, and trusses. These sections are designed to provide strength and stability to the bridge structure, allowing it to withstand the load and forces exerted on it. Each type of steel section has its own unique characteristics and is chosen based on the specific requirements and design considerations of the bridge.

- Q: How is steel wire galvanized?

- Steel wire is galvanized through a process called hot-dip galvanizing. In this method, the steel wire is first cleaned to remove any impurities and then dipped into a bath of molten zinc. The zinc coating bonds with the steel wire, creating a protective layer that helps prevent corrosion and rust. The wire is then cooled and ready for various applications.

- Q: How is steel rebar reinforced in concrete structures?

- Steel rebar is reinforced in concrete structures by placing it strategically within the concrete, typically in a grid-like pattern. The rebar is then securely tied or welded together to provide additional strength and stability to the structure. This reinforcement helps to distribute the load and prevent cracks or failures in the concrete, ensuring the overall durability and resilience of the structure.

- Q: How is steel sheet metal stamped for automotive parts?

- Steel sheet metal is stamped for automotive parts through a process called sheet metal stamping. This involves using specialized machines and tooling to cut, bend, and shape the steel into the desired automotive component. The process typically includes steps such as blanking, piercing, forming, and trimming to achieve the required shape and dimensions.

- Q: What are the different types of steel fencing and their applications?

- There are several different types of steel fencing, each with their own unique applications. Some common types include chain link fencing, ornamental steel fencing, and mesh panel fencing. Chain link fencing is often used for residential or commercial purposes due to its affordability and durability. Ornamental steel fencing is more decorative and is commonly used for residential properties or as a stylish addition to parks and gardens. Mesh panel fencing is versatile and can be used for various applications, such as securing construction sites or creating animal enclosures. Ultimately, the choice of steel fencing depends on the specific needs and requirements of the project or property.

- Q: What are the advantages of using steel in the construction of airports?

- There are several advantages of using steel in the construction of airports. Firstly, steel is a highly durable and strong material, capable of withstanding heavy loads and extreme weather conditions. This makes steel structures resilient and long-lasting, ensuring the safety and longevity of airport buildings. Secondly, steel is a versatile material that allows for flexible and efficient designs. It can be easily fabricated and customized to meet the specific needs and requirements of airport structures, such as large open spaces, wide spans, and complex geometries. This flexibility in design allows for efficient construction processes and reduced construction time. Additionally, steel is a sustainable choice for airport construction. It is a recyclable material, meaning it can be reused or repurposed at the end of its life cycle, reducing the environmental impact. Moreover, steel structures can be prefabricated off-site, resulting in less waste and disruption during construction. Furthermore, steel offers cost advantages in many cases. Although the initial cost of steel construction may be higher compared to other materials, its durability, low maintenance requirements, and ease of modification in the future can result in significant long-term cost savings. Overall, the advantages of using steel in airport construction include its durability, versatility, sustainability, and cost-effectiveness, making it an ideal choice for creating safe, efficient, and visually appealing airport structures.

- Q: How is steel used in the production of construction machinery?

- Steel is commonly used in the production of construction machinery due to its high strength, durability, and resistance to wear and tear. It is utilized in various components, such as the machine's frame, chassis, and structural elements, to provide the necessary strength and stability required for heavy-duty construction tasks. Additionally, steel is often employed in the manufacturing of buckets, blades, and other attachments, as it can withstand the demanding conditions and intense forces typically encountered in construction projects.

- Q: What are the different types of steel bolts and their uses in the automotive aftermarket?

- There are several types of steel bolts commonly used in the automotive aftermarket. Some of the most common include: 1. Hex bolts: These are standard bolts with a hexagonal head and a threaded shaft. They are used in various automotive applications such as engine mounts, suspension components, and body panels. 2. Flange bolts: These bolts have a built-in washer-like flange under the head, which distributes the load and provides a larger bearing surface. They are ideal for applications requiring a larger load-bearing capacity, such as exhaust systems and heavy-duty engine components. 3. Shoulder bolts: These bolts have a cylindrical shoulder between the head and the threaded section. They are often used in automotive applications where precise alignment or rotational movement is required, such as brake calipers and steering components. 4. U-bolts: These bolts have a U-shaped design and are used to secure leaf springs to the axle in automotive suspension systems. They provide a sturdy and reliable connection, maintaining the proper alignment and stability of the vehicle. 5. Wheel bolts: Specifically designed for securing wheels to the vehicle's hub, these bolts come in various thread sizes and lengths to accommodate different wheel types. They are crucial for ensuring the safe attachment and proper alignment of the wheels. Overall, steel bolts of different types cater to various automotive aftermarket needs, ranging from general fastening to specific applications like suspension, steering, and wheel attachment. It is essential to choose the appropriate bolt type based on the specific automotive component and its load-bearing requirements.

- Q: What are the common types of steel products used in the pet grooming and care industry?

- The common types of steel products used in the pet grooming and care industry include grooming scissors, shears, clippers, and grooming tables. These steel products are essential for various grooming tasks such as cutting hair, trimming nails, and maintaining a clean and hygienic environment for pets.

- Q: What are the different types of steel forgings and their applications in the defense industry?

- There are several different types of steel forgings used in the defense industry, each with its own unique properties and applications. Some common types include: 1. Carbon Steel Forgings: These are made from carbon steel and are known for their strength, durability, and resistance to wear and tear. They are commonly used in the manufacturing of artillery, tanks, and armored vehicles. 2. Alloy Steel Forgings: These are made by adding other elements such as chromium, nickel, or molybdenum to carbon steel, resulting in improved strength, toughness, and corrosion resistance. Alloy steel forgings find applications in the production of aircraft components, missile systems, and submarine parts. 3. Stainless Steel Forgings: These are highly corrosion-resistant and offer excellent strength and heat resistance. They are widely used in the defense industry for manufacturing firearms, ammunition, and small precision components. 4. Titanium Forgings: While not technically a type of steel forging, titanium forgings are commonly used in defense applications due to their lightweight yet high strength characteristics. They are used in the production of aircraft structures, missile components, and armor plating. Each type of steel forging has its own specific application in the defense industry, depending on the desired properties of strength, durability, corrosion resistance, or weight reduction. These forgings play a critical role in the manufacturing of various defense equipment, ensuring their reliability and performance in the most demanding conditions.

Send your message to us

PRESSED WIRE ROPE SLINGS (FIBER CORE)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords