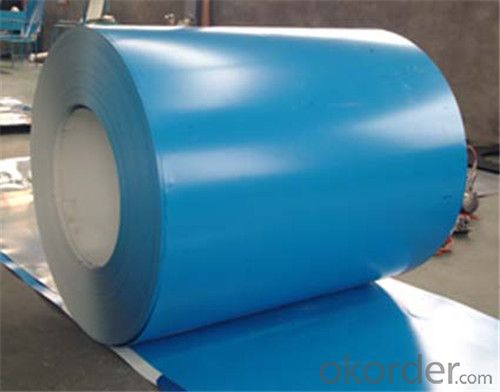

Prepainted Steel Coils, Hot-dipped Galvanized, RAL System, with good corrosion resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coil

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate,

through the surface pretreatment (degreasing, cleaning, chemical conversion

processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling.

SPECIFICATION

1.Standard: AISI, ASTM, BS, DIN, GB, JIS

2.Grade: DX51D+Z, DC51D, SPCC, SGCC, SGHC, CGCC,

3.Surface Treatment Coated: Galvanized, Paint sealant, Coating passivation solution

Substrate Cold rolled, Galvanized sheet

4.Color: RAL Color card

5.Coil ID: 508/610 mm

6.Coil weight: 4-10MT

7.Paint film Front side: 10~25um

Back side: 5~10um

8.Zinc layer: 40~180g per square meter

9.Thickness: 0.125~1.3mm

10.Width: 600~1250mm

11.Length: As requirement

12.Type: Steel plate, Steel Coil, Roofing metal

13.Place of origin: Shandong CHINA(mainland)

14.Deliver time: 20-30 days after receipt of advanced t/t or L/C

Advantages

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3.Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and

autonomous regions, and have been exported to Europe, North American, the Middle East,

the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

| commodity | prepained Galvanized Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Thickness | 0.125-1.3mm(0.16-0.8mm is the most advantage thickness)) |

| Width | Width: 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z40-180g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-10 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

- Q: I'm talking about the sort of carbon fiber that's used in the auto industry (mostly in supercars).If an object made of steel were to be copied by an exact same object, but made of carbon fiber - how lighter would the carbon fiber object be?For example, if a table is made of steel and it weighs X, how much will it weigh if it were made of carbon fiber?Thanks.

- Carbon fiber doesn't really refer to a single material (steel doesn't either, but most steels have similar densities). Pure carbon fiber is just that, fibers made of 90+% carbon. Carbon fiber in the context of cars usually refers to carbon fiber-reinforced polymers rather than plain woven fibers. The polymer adds rigidity to what would otherwise just be like a sheet of fabric. The density depends on the polymer used and the ratio of polymer:fiber. For 50% fiber by volume in epoxy, it has a density of 1.6 g/cm^3. Steel has a density of ~7.8 g/cm^3. So, by volume, steel is almost 5 times heavier.

- Q: PLEASE PLEASE PLEASE!!!!!!!! HELP MEEEEEEEE!!!!!!! I need to know how can i prevent steel from rusting when it is exposed to water or salt water or vinegar. PLEASE TELL ME A LOT OF WAYS THAT I COULD PREVENT IT!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- cathodic protection

- Q: Can steel coils be coated with anti-slip materials?

- Yes, steel coils can be coated with anti-slip materials. These materials can provide additional friction and grip to prevent slipping and sliding during transportation or handling.

- Q: How do steel coils contribute to the energy storage industry?

- Steel coils play a vital role in the energy storage industry by serving as a key component in large-scale energy storage systems such as pumped hydro storage and compressed air energy storage. These coils are used in the construction of storage tanks and pressure vessels, which are essential for storing and releasing energy on demand. Additionally, steel coils are also utilized in the manufacturing of battery systems used in grid-scale energy storage applications, providing structural support and ensuring safety and reliability.

- Q: Myself, iam Working In a Steel Fabrication Company. I completed my Engineering in 2006 and immediately recruited in this company in Oman. My company is Steel Fabrication company .So as i am new to this field, i just need some basic knowledge regarding this Steel Fabrication.Waiting for ur early reply.

- make searches on internet; it's the best way to learn.

- Q: What are the different types of steel coil surface finishes for aesthetics?

- There are several different types of steel coil surface finishes that are commonly used for aesthetics purposes. These finishes are applied to the surface of the steel coil to enhance its appearance and provide a desired aesthetic appeal. Some of the most popular types of steel coil surface finishes include: 1. Polished Finish: This type of finish involves using abrasive materials to create a smooth and reflective surface on the steel coil. It provides a high-gloss look and can be further enhanced by using different levels of polishing. 2. Satin Finish: Also known as brushed finish, this type of surface finish involves using a fine abrasive material to create a soft and matte appearance on the steel coil. It provides a subtle sheen and a textured effect. 3. Etched Finish: This finish involves using a chemical process to create patterns or designs on the surface of the steel coil. It can be used to create intricate and decorative designs, making it a popular choice for architectural applications. 4. Embossed Finish: This type of finish involves pressing or stamping a pattern onto the surface of the steel coil. It creates a raised design that adds texture and visual interest to the steel coil. 5. Powder Coated Finish: In this finish, a dry powder is applied to the steel coil and then heated to form a protective and decorative coating. It is available in a wide range of colors and provides a durable and vibrant finish. 6. Painted Finish: This type of finish involves applying a layer of paint to the surface of the steel coil. It allows for customization in terms of color and provides protection against corrosion and other environmental factors. These are just a few examples of the different types of steel coil surface finishes available for aesthetic purposes. Each finish offers a unique look and can be selected based on individual preferences and project requirements.

- Q: What are the different methods of steel coil surface cleaning?

- There are several different methods of steel coil surface cleaning, including mechanical cleaning, chemical cleaning, and high-pressure water cleaning. Mechanical cleaning involves using abrasive materials or brushes to remove dirt, rust, and other contaminants from the surface of the steel coil. Chemical cleaning involves using chemicals or solvents to dissolve or remove contaminants from the surface. High-pressure water cleaning uses water jets at high pressures to remove dirt and debris from the surface. Each method has its own advantages and is chosen based on the specific requirements and condition of the steel coil.

- Q: i want to know if i should buy a set of acrylic tapers or steel. they r close in cost so it's not a money factor i want to know which work better and if there is a downside to either. thanks!

- It relies upon on your physique and what you desire. in case you physique is allergic to a minimum of one in all them you may would desire to chosen for yet another one. If this is not any longer allergic to any, than you need to use in spite of you like the main, in simple terms attempt the two.

- Q: Can steel coils be cut?

- Yes, steel coils can be cut.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing moisture from coming into contact with the steel and causing corrosion. Additionally, the coils may be stored in a controlled environment with low humidity levels to further protect them.

Send your message to us

Prepainted Steel Coils, Hot-dipped Galvanized, RAL System, with good corrosion resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords