Prepainted Rolled Steel coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

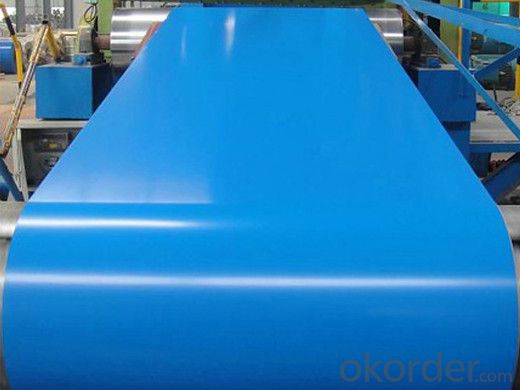

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel coil packaging machines?

- There are several different types of steel coil packaging machines available in the market. These machines are designed to efficiently and effectively package steel coils for storage, transportation, or distribution. Some of the different types of steel coil packaging machines include: 1. Automatic steel coil packaging machine: This type of machine is fully automated and can handle high-volume packaging requirements. It uses advanced technology to wrap the steel coils with a protective layer of film or paper. The machine can also apply strapping or stretch film to secure the coils during transportation. 2. Semi-automatic steel coil packaging machine: This machine requires some manual intervention to load and unload the steel coils. It is suitable for medium to high-volume packaging needs and offers a good balance between automation and cost-effectiveness. The machine typically uses a combination of wrapping, strapping, and shrinking techniques to package the coils. 3. Vertical steel coil packaging machine: This type of machine is designed specifically for packaging vertical steel coils. It can wrap the coils with a layer of film or paper, and then apply strapping or stretch film to secure them. The vertical design allows for easy loading and unloading of the coils. 4. Horizontal steel coil packaging machine: This machine is ideal for packaging horizontal steel coils. It can wrap the coils with a protective layer of film or paper, and then apply strapping or stretch film to secure them. The horizontal design ensures easy loading and unloading of the coils. 5. Customized steel coil packaging machine: Some manufacturers offer customized packaging solutions based on specific requirements. These machines can be tailored to accommodate different coil sizes, shapes, and packaging materials. They are designed to provide maximum flexibility and efficiency in the packaging process. In summary, the different types of steel coil packaging machines include automatic, semi-automatic, vertical, horizontal, and customized machines. The choice of machine depends on factors such as packaging volume, coil orientation, and specific requirements of the steel coils being packaged.

- Q: I want to know because I'm going to Hershey Park on Wednesday and Steel Force looks about the same size, so, I wanted to know. It's not that Steel Force is too big for me.

- steel force breaks the 200ft mark and is a steel out and back roller coaster. Tidal force is a water ride that is about 100 ft tall. If you can do Steel Force then you should be able to handle anything at Hersheypark. the on;y ride they have bigger is the Kissing Tower

- Q: what pokemon are week to steel type pokemon like lucario? help please, and thank you.

- Ground type pokemon are weak to steel.

- Q: and which one is better?i'm looking into buying some aftermarket headers, but companies make them in both chrome and stainless steel

- I know nothing of aftermarket headers so can't help you there, but - chrome is a coating on metal. Stainless Steel is a type of metal.

- Q: Is boron steel or carbon steel a harder metal? Which one is more flexible?

- The only thing that affects the hardness of steel is the carbon content. But there are many elements that can make it easier for a steel to achieve its maximum hardness. And Boron is an extremely effective element that increases the hardenability of steel. Adding as little as 0.002% Boron can have a big impact upon quenching of a steel. Boron is usually added when you need the hardness of a heat treated steel part to extend deep below the surface. For example, lets say you had a two identical plain carbon steel parts, but one had boron and the other didnt, and you wanted to heat treat them both After quenching, the surface should be the same on both, and lets say its 55 Rockwell C. In the plain carbon one, the hardness might drop down to 50 at 2mm under the surface, but the boron treated one might not drop to 50 until 4mm under the surface. Now, these numbers were completely made up, and it would depend on the specifics as to what the difference might be.

- Q: How do steel coil manufacturers handle international shipping requirements?

- Steel coil manufacturers handle international shipping requirements by ensuring that their products meet the necessary standards and regulations for transportation. This includes adhering to specific packaging requirements, such as utilizing appropriate containers and securing the coils to prevent damage during transit. To meet international shipping requirements, manufacturers also need to comply with customs regulations and documentation. They must prepare accurate and complete paperwork, including commercial invoices, packing lists, and bills of lading, to facilitate smooth customs clearance procedures. Moreover, steel coil manufacturers often work with freight forwarders or shipping agents who specialize in international logistics. These professionals have extensive knowledge of shipping regulations, routes, and carriers, and can assist in arranging transportation, negotiating freight rates, and handling all necessary paperwork. Manufacturers may also opt to use intermodal transportation, which involves utilizing multiple modes of transportation, such as trucks, trains, and ships, to transport their steel coils. This allows for more efficient and cost-effective shipping, especially for long-distance or international shipments. Additionally, steel coil manufacturers may consider insurance coverage to protect their products during transit. Insurance can provide financial compensation in case of any damage, loss, or delays during the shipping process. Overall, steel coil manufacturers handle international shipping requirements through careful planning, compliance with regulations, collaboration with experts in logistics, and consideration of various transportation options. This helps ensure that their products reach international destinations safely, on time, and in compliance with all relevant regulations.

- Q: i want to know what is light gauge steel and the diffrences between light gauge steel and steel for roof truss.

- guage means thickness.

- Q: I know that it is used for katanas and swords but what is it and is it good i am pretty sure that it is the process of the steel but can I have a little more information.

- Damascus or Wootz was a type of steel that appeared around 300BC It originated in India before spreading throughout Asia and the Middle East. It was considered a good steel, and for it's date of origin, exceptionally advanced for the level of technology in the ancient world. However the techniques to create the steel were lost forever after a decline in the swords manufacturing. The most popular theory is that the metal containing the required trace elements became less available over time due to unreliable trade routes. In the modern area, many scientists and metallurgists have studied the surviving blades, resulting in many discoveries such as evidence of carbon molecules fused in a crystalline structure. While the blades do provide some clues, it's only a small part of a much bigger picture as to the full process of the metal from raw to finished product. Now many have claimed to have recreated Damascus/Wootz steel, but none are recognised as being authentic. It has become a market ploy these days that draws people to purchasing the blades but all you are actually seeing is one of the many various forms of folded or patterned steel, which has varying degrees of quality, strength etc. We do know the steel was folded similar to the way the Japanese did in creation of old Katana, so often people will sell Damascus steel Katana that are nothing but folded steel swords like others. (Which is beautiful and traditional, but was a process designed to uniform impurities in the metal, something we no longer need to do with modern metals)

- Q: Search the internet for 'Frost Clipper Knife'. This knife comes in either stainless or carbon steel. I have a friend who has one (stainless steel) and he is very impressed with it, but I have heard that Carbon Steel blades are better? Discuss...

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Stainless okorder

Send your message to us

Prepainted Rolled Steel coil for Construction Roofing constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords