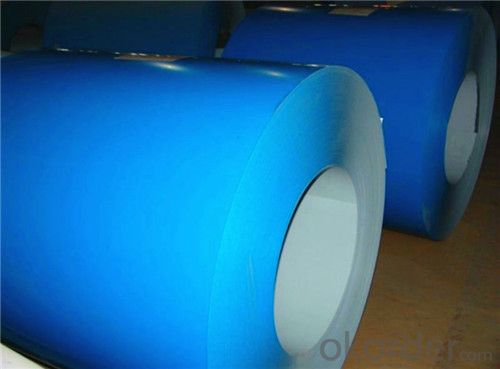

Prepainted Rolled steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel coils available?

- There are several types of steel coils available, including hot rolled coils, cold rolled coils, galvanized coils, stainless steel coils, and coated coils.

- Q: in a lab at school we did heat treatment of steelwhat are the possible phases present in the steel sample in as-received, as-quenched and as-tempered conditions? specifically when is it ferrite, austenite and pearliteis the steel originally in the ferrite phase? then when headed turns into austenite and when quenched martensite is formed and when tempered cermentite is formed...........where is pearlite involved and am i correct about the ferrite?

- hey from what i learned in uni last sem, steel is originally ferrite form at first at room conditions. it will undergo poly morphic transformation to become FCC structure austenite form at 912 degree celcius. under conditions, it can become pearlite (which is a combination of ferrite and cementite) or bainitie( a finer form of pearlite). queching conditions to room temperature will form martensite which is the strongest but brittle steel form. tempered cementite is formed when we quench it and then raise temperatures before sir cooling. hope it helps, pls vote me best answer is i deserve it. thanks

- Q: i have been playing with hand me down graphite shaft irons and wedges. i was wondering if someone of my stature (5'3, 90 lbs., 12 years old) should be using steel shafted irons. i can definately swing them im just wondering if they are better for making contact

- It depends on your swing speed. If you have a faster swing speed and notice you are consistently hitting high with your irons and having some trouble with accuracy, you will benefit from playing steel shafted irons. If your swing speed is on the slower end of the spectrum, stick with the graphite irons for a couple more years until you swing has developed and you are hitting farther.

- Q: What are the different methods of slitting steel coils?

- There are several methods of slitting steel coils, including rotary slitting, wobble slitting, and crush cutting. Rotary slitting involves using circular knives to cut through the steel coil, while wobble slitting uses a wobbling blade that moves from side to side. Crush cutting, on the other hand, involves crushing the steel coil between two rotating blades to create a clean cut. These methods offer different advantages and are chosen based on the specific requirements of the steel coil slitting process.

- Q: What are the dimensions of steel coils used in the power generation industry?

- The dimensions of steel coils used in the power generation industry can vary depending on the specific application and requirements. However, in general, steel coils for power generation are typically available in various sizes and thicknesses. The width of steel coils used in power generation can range from a few inches to several feet, depending on the specific equipment or machinery they are intended for. These coils are often designed to fit specific manufacturing processes or components within power generation systems. The thickness of steel coils used in the power generation industry can also vary significantly. Thicker coils are commonly utilized for heavy-duty applications that require increased strength and durability, while thinner coils may be suitable for less demanding tasks or where weight reduction is a priority. Additionally, the weight of steel coils used in power generation can vary depending on their dimensions and the specific steel material being used. The weight is an essential consideration during transportation, installation, and handling of the coils. It is important to note that the dimensions of steel coils used in the power generation industry can be customized to meet specific project requirements. Manufacturers typically work closely with power generation companies to understand their needs and provide tailored solutions that meet their dimensional specifications.

- Q: How are steel coils used in the production of shipbuilding materials?

- Steel coils are used in the production of shipbuilding materials as they are typically cut and shaped into plates, sheets, or beams that are then used to construct various components of a ship's structure such as the hull, decks, and bulkheads. The coils provide a reliable and durable base material that can withstand the harsh marine environment and ensure the structural integrity and strength of the ship.

- Q: Can steel coils be cut?

- Yes, steel coils can be cut.

- Q: Can steel coils be coated with light-reflective materials?

- Yes, steel coils can be coated with light-reflective materials.

- Q: I am trying to clean up a stainless steel back splash and some kitchen appliances that have brown spots that look like rust spots. I was able to remove most of them with stainless steel cleaner but does anyone know any tricks?

- This Site Might Help You. RE: How do I remove rust spots from stainless steel? I am trying to clean up a stainless steel back splash and some kitchen appliances that have brown spots that look like rust spots. I was able to remove most of them with stainless steel cleaner but does anyone know any tricks?

- Q: i want a good modern carbon steel (not stainless) knife. trying to keep it under 50$ also nothing to gruesome just a small pocket knife. thank you

- Well, okorder /... They did make other folders in M2 steel, but the thing is those are out of production and the cost is very high. Spyderco made M4 steel folder knives, and so did Benchmade. Although,both are outside of 50$ budget. I guess Opinels are best option.

Send your message to us

Prepainted Rolled steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords