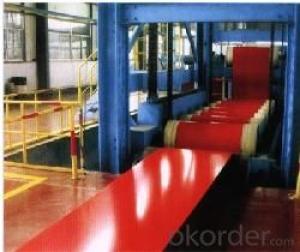

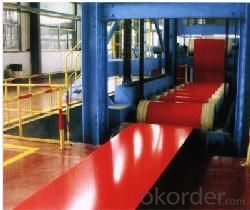

Prepainted Galvanized Steel Coil RAL5012

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,BS,GB,JIS,GB/T 13912-2002 | Grade: | CGCC | Thickness: | 0.15-0.8mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | Type: | Steel Plate | |

| Technique: | Hot Rolled | Surface Treatment: | Galvanized | Application: | construction industry; automobile making |

| Special Use: | High-strength Steel Plate | Width: | 0.15-0.8mm | Length: | On Request |

| Color: | On Request | Certificate: | ISO9001TUV | Zinc Coating: | Z60-Z150 or on request |

| Payment: | L/C T/T | Usage: | Buldings | Package: | Standard Export Packing |

| Type of Company: | Manufacturer | MOQ: | 25 Tons | Coil weight: | 3-8MT |

Packaging & Delivery

| Packaging Detail: | Standard Export Packing for the goods pallet packing or according to customer's request |

| Delivery Detail: | within 15-45 days after the receipt of L/C or deposit |

Specifications

Thickness: 0.15-0.8mm

Width: 700-1250mm

Length: On Request

Product Description

Prepainted Galvanised Steel Sheet

Thickness: 0.15-1.5mm

Width: 700-1250mm

Length: As your request

Zinc Coating: 60-150g/ m² or as your request

Advantage:

| HIGH QUALITY |

| LOW PRICE |

| FAST DELIVERY |

Application:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

- Q: How are steel coils loaded onto a truck?

- Steel coils are typically loaded onto a truck using specialized equipment such as cranes, forklifts, or coil trailers. The coils are lifted or rolled onto the truck bed, ensuring proper distribution of weight and secure fastening to prevent any movement during transportation.

- Q: Can steel coils be used in the production of medical equipment?

- Yes, steel coils can be used in the production of medical equipment. Steel is a versatile material known for its strength, durability, and ability to withstand various environmental conditions. It is commonly used in the manufacturing of medical equipment such as surgical instruments, orthopedic implants, hospital beds, and diagnostic machines. Steel coils are often utilized as a raw material in the production process. They can be processed and formed into various shapes, sizes, and components required for medical equipment. The coils can be cut, shaped, and welded to create intricate parts with precise specifications, ensuring the quality and performance of the final product. Moreover, steel coils can be surface-treated to enhance their corrosion resistance, making them suitable for use in medical environments where cleanliness and hygiene are crucial. Coatings such as electroplating or powder coating can be applied to provide an additional layer of protection against rust and other forms of degradation. Furthermore, steel is a cost-effective material, which makes it an attractive choice for medical equipment manufacturers. Its availability and affordability make it a preferred option for producing high-quality medical devices while keeping the production costs manageable. In summary, steel coils can indeed be used in the production of medical equipment. Their strength, durability, versatility, and cost-effectiveness make them an ideal choice for manufacturing various components and instruments used in the healthcare industry.

- Q: Can steel coils be stored vertically?

- Yes, steel coils can be stored vertically.

- Q: What are the common applications of pre-painted steel coils?

- Pre-painted steel coils are commonly used in various industries for applications such as roofing, siding, wall cladding, and appliances. They provide a durable and aesthetically pleasing finish, making them ideal for both residential and commercial construction projects. Additionally, pre-painted steel coils are also utilized in automotive manufacturing, electrical enclosures, and industrial equipment due to their corrosion resistance and versatility.

- Q: What would be a better knife one with damascus steel or one without? Why is damascus steel so special other than the look? And why do some people say high carbon steel is better than regular? mainly though I want to know about the damascus. Thanks, max points to best answer.

- It all depends on the steel. There are as many types of Damascus as you want to imagine. The old Damascus swords brought back by the Crusaders were far superior to the blades made in Europe at that time, but they probably wouldn't match up to modern steel in performance. Alas, it has been lost to history as to how they were made. Back to modern times. Damascus can be homogeneous steel with the pattern hammered in (hammered steel) or layered (pattern welded) or any number of variations. I make many blades out of crane cable, the pattern is nice and the strength is superior to all others. Layered damascus, done correctly, can have what is called the Damascus cutting effect (DCE). These knives are rare and expensive. The best layered blades are made of high carbon steels of various alloy content. I just recently finished a low count blade made of L-6 and a file (W-1), these offer exceptional edge holding. Factory blades are often not worth buying unless you like pretty knives. I personally make mine to be used. I could write a book on the subject, but others already have. In the end a knife is as only as good as the heat treating, good steel with a bad heat treat will not perform as well as lower quality steel done properly.

- Q: How hot does steel have to get before it will melt?

- Type your query into Yahoo! Search or other search engines to get the answer: It depends, since steel usually has different metals added for various properties (strength, corrosive resistance, etc.)

- Q: What are the dimensions of steel coils used in the pipeline industry?

- The specific application and requirements play a significant role in the variation of dimensions for steel coils utilized in the pipeline industry. Generally, the dimensions for steel coils used in this industry fall within the range of 0.5 to 3.0 inches in thickness and 24 to 60 inches in width. The length of the coils can also vary, with standard lengths typically falling between 100 and 200 feet. These dimensions are carefully chosen to ensure the necessary strength and durability for pipeline construction and the transportation of various fluids and gases. It is crucial to acknowledge that these dimensions may differ depending on the project's specifics and the standards set by the industry.

- Q: How are steel coils used in the manufacturing of electrical equipment?

- Steel coils are used in the manufacturing of electrical equipment as they provide structural support and help in the efficient transfer of electrical energy. They are commonly used in transformers, motors, and generators to create magnetic fields that enable the conversion and transmission of electrical power.

- Q: How are steel coils used in the production of agricultural machinery?

- Steel coils are used in the production of agricultural machinery as they are a key component in the manufacturing of various parts. These coils are used to create durable and strong components such as frames, chassis, and structural supports, which are essential for the heavy-duty requirements of agricultural machinery. The steel coils are shaped, cut, and welded to create these components, ensuring the machinery can withstand the demanding conditions of farming operations.

- Q: What are the common uses of cold rolled steel coils?

- Cold rolled steel coils are commonly used in a variety of industries and applications. They are frequently utilized in the automotive industry for manufacturing parts such as automobile bodies, frames, and components. Cold rolled steel coils are also widely employed in construction for producing structural components, roofing, and siding. Additionally, they are used in the manufacturing of appliances, furniture, and various electrical products. The smooth and consistent surface of cold rolled steel coils makes them ideal for applications that require a high-quality finish, such as in the production of kitchen utensils and decorative items.

Send your message to us

Prepainted Galvanized Steel Coil RAL5012

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords