China 3003 Aluminum Coil for Decoration Materials Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

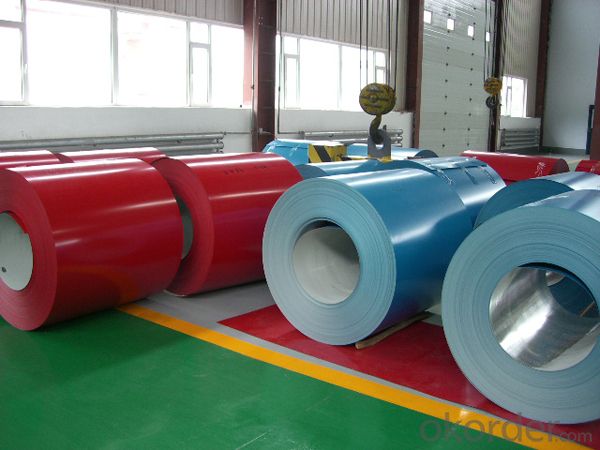

Prepainted Aluminium Coil For Decoration Materials Production

Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

Thickness | 0.1mm to 6mm |

Width | 20mm to 3300mm |

Coil weight | 100kgs to 6 tons depends on actual requirement |

Core material | Aluminum or paper |

Coil inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

Appplication | construction, roofing, decoration, lamping etc |

Package | eye to wall or eye to the wall for aluminum coil with wood pallet (wooded case also available) |

Characteristics

1) Excellent weather-proof durability

2) Anti-ultraviolet

3) Glass curtain wall frame

4) Interior decoration

5) Elevator decoration

6) Signs, nameplate, bags making.

7) Automobile parts material

8) Office and Household appliances: HVAC equipments

9) The consumer electronics: mobile phones, digital cameras, MP3 .etc.

Coating varieties

Polyester Coatings (PE)

PE (polyester) coatings exhibit an excellent combination of hardness, flexibility, flow, appearance, and superior resistance to dirt retention in indoor and outdoor applications. These coatings are highly resistant to abrasion, metal marking, staining, and marring, and require minimal maintenance. Glazetech uses polyester paints which provide excellent colour and gloss retention properties.

Polyvinylidene Fluoride Coatings (PVDF)

PVDF (polyvinylidene fluoride) is a chemical resistant thick film barrier coating commonly used in architectural applications where both excellent appearance and substrate protection must be maintained over a long period of time. This coating is unaffected by most chemicals and solvents and has excellent wear and abrasion resistance. PVDF also has a high dielectric strength, excellent resistance to weathering and the ability to self extinguish.

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What’s the coating of top side?

--A: PVDF and PE coating

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: Can aluminum coils be used for architectural applications?

- Aluminum coils are indeed applicable for architectural purposes. With its versatility and lightweight nature, aluminum is an ideal material that boasts exceptional resistance against corrosion, making it suitable for numerous architectural applications. Exterior cladding, roofing, facades, and even interior uses like ceilings and wall panels can all benefit from the utilization of aluminum coils. These coils are easily malleable, cuttable, and moldable, allowing for flexibility in design and innovative architectural solutions. Moreover, aluminum coils can be coated with diverse finishes, such as paint or anodized coatings, to enhance both aesthetics and durability. All in all, due to their adaptability, durability, and aesthetic charm, aluminum coils are highly favored within the architectural industry.

- Q: Are there any specific regulations for the disposal of aluminum coil waste?

- Yes, there are specific regulations for the disposal of aluminum coil waste. The disposal of aluminum coil waste is subject to various environmental regulations to ensure proper handling and prevent any potential harm to the environment and human health. One of the key regulations is the Resource Conservation and Recovery Act (RCRA) in the United States. Under this act, aluminum coil waste is considered a hazardous waste if it exhibits certain characteristics such as ignitability, corrosivity, reactivity, or toxicity. If the waste meets these criteria, it must be managed as hazardous waste and disposed of in accordance with RCRA regulations. This may involve treatment, storage, and disposal at an approved hazardous waste facility. Additionally, the Environmental Protection Agency (EPA) has established guidelines for the disposal of non-hazardous aluminum coil waste. These guidelines typically require proper storage, labeling, and transportation of the waste to an authorized disposal facility. The disposal facility should be equipped to handle and process the waste in an environmentally responsible manner. In many countries, including the United States, local, state, and federal regulations may also apply to the disposal of aluminum coil waste. These regulations may vary depending on the specific location and the nature of the waste. It is crucial for businesses and individuals involved in the disposal of aluminum coil waste to familiarize themselves with the applicable regulations to ensure compliance and avoid potential penalties. Overall, it is important to follow the specific regulations for the disposal of aluminum coil waste to protect the environment, prevent pollution, and ensure the safety of individuals involved in waste management.

- Q: What should pay attention to transporting aluminum coil?

- You must ensure the good property of the aluminum coil.

- Q: How do aluminum coils contribute to noise isolation?

- Aluminum coils contribute to noise isolation by acting as a barrier to the transmission of sound waves. The coils are designed to absorb and dampen vibrations, reducing the amount of noise that can pass through them. They are often used in various applications, such as in HVAC systems or soundproofing materials, to enhance noise isolation and create a quieter environment.

- Q: im looking for a bat but i dont know what to get wood or aluminum what is harder wood or aluminum ?? what would be better for hitting hard balls with ( or maybe people ) haha no im joking i need help !!!!

- aluminum is, and hardness isnt everything.. theres bat speed, vibration differences after the swing, wider sweet spots, and durability. aluminum bats dominate wood bats in all these catergories

- Q: How do aluminum coils contribute to sustainable energy systems?

- Aluminum coils play a crucial role in sustainable energy systems due to several reasons. Firstly, aluminum is a lightweight and highly conductive metal, making it an ideal material for the production of coils used in various renewable energy technologies such as wind turbines, solar panels, and electric vehicles. The lightweight nature of aluminum reduces the overall weight of these systems, thus increasing their efficiency and performance. Secondly, aluminum is abundant in nature and has a high recycling rate. It can be recycled repeatedly without losing its original properties, resulting in significant energy savings and reduced environmental impact. By using aluminum coils, sustainable energy systems can minimize their reliance on virgin materials and promote a circular economy. Furthermore, aluminum coils are corrosion-resistant and have excellent heat transfer properties. This makes them highly durable and capable of withstanding harsh weather conditions, ensuring the longevity and reliability of renewable energy systems. The durability of aluminum coils also reduces the need for frequent maintenance or replacements, thereby minimizing waste generation and conserving resources. Moreover, aluminum is a non-toxic material that poses minimal risks to human health and the environment. Unlike other metals, aluminum does not leach harmful substances into the soil or water, making it a safe choice for sustainable energy systems. Lastly, the use of aluminum coils in sustainable energy systems helps to reduce greenhouse gas emissions. As aluminum is lightweight, it requires less energy to transport and install, thereby reducing the carbon footprint associated with the manufacturing and installation processes. Additionally, the increased efficiency and performance of renewable energy systems using aluminum coils contribute to the displacement of fossil fuel-based energy generation, leading to a reduction in overall carbon emissions. In conclusion, aluminum coils contribute to sustainable energy systems by enhancing the efficiency, durability, recyclability, and environmental friendliness of renewable energy technologies. Their lightweight nature, corrosion resistance, and excellent heat transfer properties make them ideal for various applications, while their abundance and recyclability promote resource conservation and a circular economy. By using aluminum coils, sustainable energy systems can reduce their environmental impact, improve performance, and contribute to a cleaner and more sustainable future.

- Q: high-quality hi-fi power and amplifiers generate large amounts of heat. to dissipate the heat and prevent damage to the electronic components, heat-radiating metal fins are used. would it be better to make these fins out of iron or aluminum? specific heat capacities for aluminum and iron are 0.89 J/degrees C.g and 0.45 J/degrees C.g, respectively. explain your answer

- Aluminum has high specific heat than iron which means more energy is require to change aluminum temperature than it of iron. A good conductor is a good emmiter so aluminum will be a best choice since it will not heat up as much as iron for the same amount of mass and energy imput.

- Q: How is an aluminum coil made?

- An aluminum coil is made through a process called aluminum coil rolling, which involves several stages of manufacturing. The process begins with casting, where molten aluminum is poured into large molds to form large ingots or billets. These ingots are then heated to a specific temperature to improve their malleability. Once heated, the ingots are hot-rolled into thin strips using heavy machinery known as hot rolling mills. During this process, the ingots are passed through a series of rollers that gradually reduce their thickness while increasing their length. This continuous hot rolling ensures a uniform thickness and smooth surface finish. After hot rolling, the aluminum strips are cooled and then subjected to further processing. They are often subjected to cold rolling, which involves passing the strips through cold rolling mills. Cold rolling further reduces the thickness of the aluminum strips, creating the desired gauge or thickness required for the final product. To improve the mechanical properties and surface finish of the aluminum, the cold-rolled coils may undergo additional processes such as annealing, tempering, or surface treatment. Annealing involves heating the coils to a specific temperature and then slowly cooling them to relieve internal stresses and improve their ductility. Tempering is a similar process that involves reheating the coils to a lower temperature than annealing. Once the desired properties are achieved, the aluminum coils are typically trimmed, cut, and packaged into coils or sheets, ready for distribution or further fabrication. These coils can be used in various industries, such as construction, automotive, aerospace, and packaging, where their lightweight, corrosion resistance, and excellent thermal conductivity make them highly sought after materials.

- Q: I live around Minneapolis, MN. Is there a place that you can recycle crushed aluminum cans for money around here?

- Recycling aluminum benefits the economy, the community and the environment and can make you money. Aluminum can be recycled over and over again. Recycled aluminum will make it back to the product market within 60 days after recycling. Any type of aluminum is recyclable. Schools, organizations and sport teams commonly use this as a method to raise money. There is no out-of-pocket expense. You will simply need to set up a designated area for receiving the aluminum and then transport it to the recycling station OR Put crushed aluminum cans in the recycling bin.They are processed the same way. I used to have a can-crusher, a little hand operated press that flattened cans out for easy keeping and storage. You could get a lot more of them into a box and they still were worth the nickel if you lived in CA or other states that refunded on cans. :)

- Q: How are aluminum coils protected against corrosion during storage?

- Aluminum coils are protected against corrosion during storage through various methods such as applying a protective coating, using desiccants or moisture-absorbing materials, ensuring proper ventilation, and storing them in a dry and controlled environment to prevent exposure to moisture and other corrosive elements.

Send your message to us

China 3003 Aluminum Coil for Decoration Materials Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords