3003 H12 Aluminum Coil China Supply for Sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of AA1100 H12 Aluminum Coil China Supply for Sales

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of AA1100 H12 Aluminum Coil China Supply for Sales

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of AA1100 H12 Aluminum Coil China Supply for Sales

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

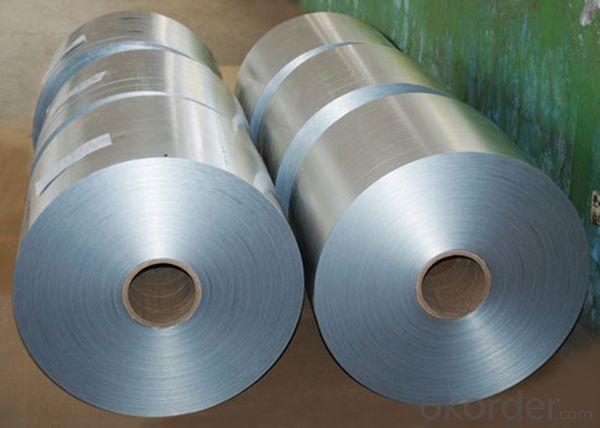

5. Image of AA1100 H12 Aluminum Coil China Supply for Sales

6. Package and shipping of AA1100 H12 Aluminum Coil China Supply for Sales

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for lightweight panel applications?

- Yes, aluminum coils are suitable for lightweight panel applications. Aluminum is known for its lightweight and corrosion-resistant properties, making it an excellent choice for lightweight panel applications. Aluminum coils can be easily formed and shaped into panels of varying sizes and thicknesses, making them highly versatile. Additionally, aluminum has a high strength-to-weight ratio, allowing for the creation of strong and durable lightweight panels. These panels find applications in various industries such as automotive, aerospace, construction, and transportation, where weight reduction is important. Overall, aluminum coils are a suitable choice for lightweight panel applications due to their lightweight nature, corrosion resistance, versatility, and strength.

- Q: What happened to the aluminum coil coming out of the annealing furnace?

- There is oil on the aluminum coil and the annealing time is too long.

- Q: What specific tools are required for handling and working with aluminum coils?

- <p>Working with aluminum coil typically requires specialized tools to ensure safety and efficiency. Essential tools include a coil cutter for precise cutting, a coil car for easy transportation, and a decoiler for unrolling the coil. Additionally, protective gloves and safety glasses are crucial for personal protection. For more complex tasks, a shear machine or press brake may be necessary for shaping the aluminum. Always follow safety guidelines and use the appropriate tools for the job to prevent accidents and ensure quality work.</p>

- Q: What is the composition of aluminum coils?

- Aluminum coils are typically composed of a pure aluminum core, which is surrounded by a protective coating or cladding material on both sides. The cladding material can vary and may include alloys such as aluminum-manganese, aluminum-magnesium, or aluminum-zinc, depending on the specific application and desired properties.

- Q: What are the tensile strength properties of aluminum coils?

- The tensile strength properties of aluminum coils can vary depending on the specific alloy and temper of the aluminum. Generally, aluminum has a good tensile strength, ranging from 70 to 700 MPa (megapascals). The specific tensile strength of aluminum coils can be determined through material testing and analysis.

- Q: What is the corrosion resistance of aluminum coils?

- Aluminum coils exhibit excellent corrosion resistance due to the formation of a protective oxide layer on its surface. This oxide layer acts as a barrier, preventing further corrosion and providing long-term durability. The corrosion resistance of aluminum coils is further enhanced through various surface treatments and coatings, such as anodizing or painting, which provide an additional layer of protection. This makes aluminum coils a reliable choice for a wide range of applications in industries such as construction, automotive, and aerospace, where resistance to corrosion is essential.

- Q: Are aluminum coils resistant to impact damage?

- Aluminum coils, in general, possess resistance to impact damage. The strength-to-weight ratio and durability of aluminum render it less vulnerable to impact damage in comparison to alternative substances. Moreover, aluminum coils are commonly employed across diverse industries, where they encounter a range of environmental conditions and handling procedures, and are engineered to endure such impacts without succumbing to damage. Nevertheless, it is crucial to acknowledge that the degree of impact resistance may fluctuate depending on the precise thickness, quality, and design of the aluminum coil.

- Q: What is the cost-effectiveness of using aluminum coils compared to other materials?

- The cost-effectiveness of using aluminum coils compared to other materials is generally favorable. Aluminum coils are lightweight, durable, and corrosion-resistant, which reduces maintenance and replacement costs. They also have excellent heat transfer properties, leading to energy efficiency and cost savings in heating and cooling systems. Additionally, aluminum is a widely available and recyclable material, lowering the overall cost and environmental impact.

- Q: How is Aluminum formed??Thanks!!

- okorder nice.

- Q: What are the typical dimensions for aluminum coils?

- <p>The standard size of aluminum coils can vary depending on the specific application and industry requirements. Commonly, aluminum coils are available in widths ranging from 600mm to 2000mm and thicknesses from 0.2mm to 6.0mm. The length of the coils can be from 500 meters to over 3000 meters, depending on the weight and the manufacturing process. It's important to note that these dimensions are not fixed and can be customized to meet specific project needs.</p>

Send your message to us

3003 H12 Aluminum Coil China Supply for Sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords