Precio Geotextil High Tensile Non Woven Polypropylene Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of High Tensile Non Woven Polypropylene Geotextile Description:

High Tensile Non Woven Polypropylene Geotextile Made from PP (polypropylene) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function.

Main Features of the Non Woven Polyester Geotextile :

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2) Filament geotextile:

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

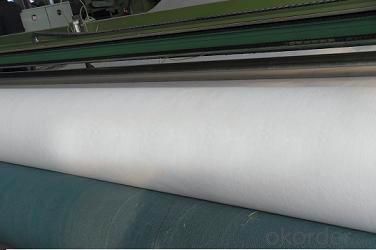

Non Woven Polyester Geotextile Images

Non Woven Polyester Geotextile Specification:

1) Weight / Mass: 100g/m2-1500g/m2 .

2) Width: Within 8 m (1m-8m as request ).

3) Length: 50m-100m/roll (as request).

4) Material: PP / PET .

5) Certificate: CE/ISO9001/ISO14001

6) Manufacturing method: nonwoven / woven.

| c | Item | Value | Note | ||||||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

| 1 | Weight Variation(%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

| 2 | Thickness(mm)≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 | |

| 3 | Width Variation% | -0.5 | |||||||||||

| 4 | Breaking Strength( KN/m)≥ | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 13 | 14 | 16 | 19 | 25 | MD and TD |

| 5 | Elongation at break% | 25-100 | |||||||||||

| 6 | CBR Mullen Burst Strength KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 | |

| 7 | Sieve Size O90(mm) | 0.07-0.2 | |||||||||||

| 8 | Vertical Permeability Coefficient cm/s | K×(10-1-10-3) | K=1.0-9.9 | ||||||||||

| 9 | Tearing Strength KN≥ | 0.08 | 0.12 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.6 | MD and TD |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geotextiles be used for reinforcement of embankments?

- Yes, geotextiles can be used for reinforcement of embankments. Geotextiles are commonly used in civil engineering projects to improve the stability and strength of embankments. They provide reinforcement by distributing and dissipating forces, preventing soil erosion, and enhancing the overall performance and longevity of the embankment structure.

- Q: Geotechnical construction of the weather when there is any requirement

- Hello, geotextile construction is very simple, laying with less cutting, less overlap for the principle. Take the head set aside about 25 cm. Using double take the head, sew two lines. This is in principle to ask this, the general construction can not do so carefully. Huazhi geotechnical materials manufacturers to answer, need to talk.

- Q: Can geotextiles be used for reinforcement in asphalt overlays?

- Yes, geotextiles can be used for reinforcement in asphalt overlays. Geotextiles are commonly used to improve the performance and longevity of asphalt overlays by providing reinforcement and mitigating cracking. They help distribute the load and stresses, reduce reflective cracking, and improve the overall structural integrity of the pavement.

- Q: Can geotextiles be used for reinforcement of railway embankments?

- Yes, geotextiles can be used for reinforcement of railway embankments. Geotextiles are commonly used in civil engineering projects for their ability to provide separation, filtration, and reinforcement functions. When used in railway embankments, geotextiles help improve the stability and strength of the embankment by preventing the mixing of different soil layers, reducing soil erosion, and distributing load more evenly. Overall, geotextiles are an effective solution for reinforcing railway embankments and enhancing their long-term performance.

- Q: Geotextile is used to do anything

- Geotextiles have multiple varieties, there are a variety of uses, different varieties have a different emphasis on different functions. Woven geotextile, or geotextile, can be used for foundation treatment in the reinforcement and isolation and filtration. Non-woven geotextile, mainly used for foundation treatment in the filter and isolation. Can also be used in other projects in the filter. Nonwovens for the example of the filter: now in the municipal engineering around the Yinjing, often because the surrounding groundwater into the Yinjing will take away part of the soil, resulting in the loss of soil around the wells, the results in the perimeter around the wells There is a collapse phenomenon, if the circle around the perimeter of the laying of non-woven geotextile, the side can play a role in filtering, so that groundwater can flow into the Yinjing, but the soil will not lose the purpose of the perimeter around the soil There will be no collapse of the phenomenon.

- Q: How do geotextiles contribute to pavement performance?

- Geotextiles contribute to pavement performance by improving the overall strength and durability of the pavement. They act as a reinforcement layer, preventing the migration of fine particles and providing separation between the subgrade and base layers. This helps to distribute the load evenly, reduce pavement deformation, and increase its resistance to cracking and rutting. Additionally, geotextiles can enhance drainage and reduce water infiltration, preventing moisture-related issues such as frost heave or base erosion. Overall, geotextiles play a crucial role in enhancing the longevity and performance of pavements.

- Q: Are geotextiles suitable for use in geotextile tube dewatering systems?

- Yes, geotextiles are suitable for use in geotextile tube dewatering systems. Geotextiles are designed to provide filtration, separation, and reinforcement functions, making them ideal for use in dewatering systems that require the removal of water from sediments or sludge. The permeable nature of geotextiles allows water to pass through while retaining solids, ensuring efficient dewatering and sediment containment.

- Q: How do geotextiles reduce hydraulic pressure in soil?

- Geotextiles reduce hydraulic pressure in soil by acting as a barrier that allows water to pass through while preventing soil particles from being washed away. This allows for better drainage and prevents the build-up of excess water pressure in the soil.

- Q: Geotextile is what to do with

- Geotextile is reinforced and segregated, reinforced mainly to enhance the ability of materials to shear and tensile deformation, to prevent the reflection of cracks in the road; isolation is the separation of different materials to maintain their performance; because the geotextile itself is not waterproof, In the old road renovation over the asphalt mixture will form impermeable complex, in addition to preventing cracks will have a certain waterproof effect. The roadbed refers to the strip structure that is built on the basis of the route position and certain technical requirements. It is the basis of the railway and the road. The roadbed is a linear structure made of soil or stone. Built in good geological, hydrological, climatic conditions under the roadbed. From the material points, subgrade can be divided into soil subgrade, stone roadbed, earth and rock roadbed three.

- Q: Composite geotextile per square meter of labor costs how much money 'sewage treatment pool' ground plane 'square meters. More

- The cost of 2-5 yuan ranging from the specific needs to see you as well as construction machinery personnel

Send your message to us

Precio Geotextil High Tensile Non Woven Polypropylene Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords