Geotextil Y Geomembrana Non Woven Polypropylene Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

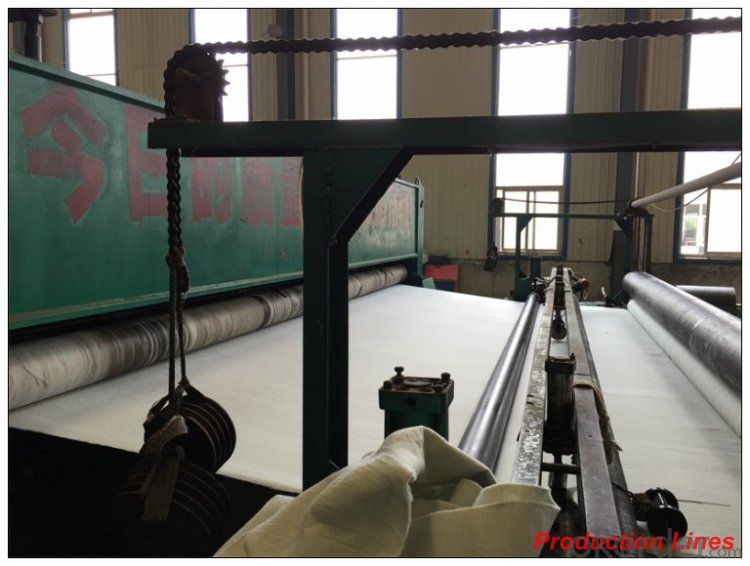

PP Non Woven Description:

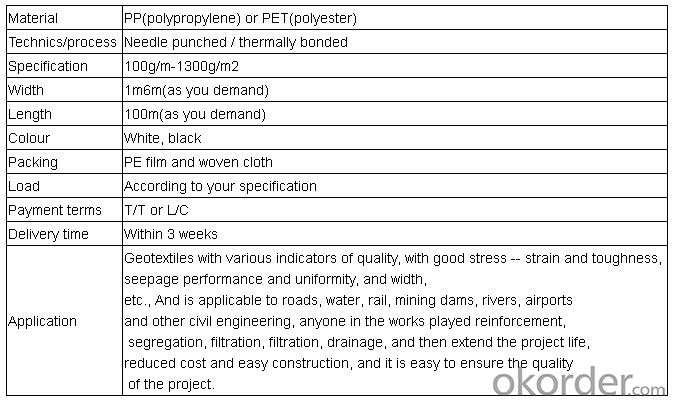

Specifications of PP Non Woven Geotextile for Road Construction:

1, Biggest Width: 6meter

2, Weight: about 90 gram to 800 gram

3, Treatment: UV protect

Application PP Non Woven Geotextile for Road Construction:

A: Subsurface drainage

B: Roadway separation

C: Hard armor underlayment

D:Asphalt overlay applications

Specification PP Non Woven Geotextile for Road Construction:

Functions and Features for PP Non Woven Geotextile for Road Construction:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What is the purpose of using geotextiles?

- The purpose of using geotextiles is to provide reinforcement, separation, filtration, and drainage in various civil engineering and construction applications. Geotextiles help improve soil stability, prevent erosion, control sediment migration, and enhance the overall performance and longevity of infrastructure projects.

- Q: 300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q: What kind of geotextiles are used in highway geotextiles?

- Highway geotextile is a new type of civil artifacts material, for the construction of geotextile highway can also be Hongxiang filament geotextile, not only need to resist the complex stress under the comprehensive mechanical properties of tensile properties, etc. But also to ensure that a variety of natural factors under the influence of a long time, the overall performance does not produce significant attenuation, that is, long-term stability, high and low temperature performance, anti-aging properties. Hongxiang filament geotextile can improve the carrying capacity of the road, can improve the road in the process of using the structure of the destruction of the problem

- Q: 300 grams of geotextile how much money a square meter

- See the requirements of the data indicators in general about 2.4 Huazhi geotextile material manufacturers

- Q: Can geotextiles be used in tunnel construction?

- Yes, geotextiles can be used in tunnel construction. Geotextiles are often used as reinforcement materials to improve the stability and strength of tunnel walls. They help to prevent soil erosion, control water flow, and provide additional support to the tunnel structure.

- Q: How do geotextiles help with filtration?

- Geotextiles help with filtration by providing a barrier that allows water to pass through while retaining soil particles and other contaminants, preventing their migration.

- Q: What are the factors that affect the effectiveness of geotextiles in erosion control?

- The effectiveness of geotextiles in erosion control is influenced by several factors. Firstly, the material and quality of the geotextile itself play a significant role. Geotextiles with higher tensile strength and durability are more effective in preventing erosion. Secondly, the design and installation of the geotextile are crucial. Proper placement and anchoring techniques ensure that the geotextile remains in place and functions effectively. The type and intensity of the erosive forces also impact the effectiveness of geotextiles. Factors such as water flow rate, soil type, slope gradient, and vegetation cover can affect how well the geotextile mitigates erosion. Additionally, the maintenance and regular inspection of the geotextile are important for its long-term effectiveness. Overall, a combination of material quality, proper installation, and consideration of site-specific conditions contribute to the effectiveness of geotextiles in erosion control.

- Q: How do geotextiles affect soil settlement?

- Geotextiles can help reduce soil settlement by providing reinforcement and stabilization. They act as a barrier that distributes the load from structures evenly, preventing differential settlement. Additionally, geotextiles improve soil drainage, allowing excess water to flow through while retaining the soil particles, which further aids in minimizing settlement.

- Q: How do geotextiles help with asphalt pavement reinforcement?

- Geotextiles help with asphalt pavement reinforcement by providing additional strength, stability, and durability to the pavement structure. They are placed between the asphalt layers to prevent the mixing of subgrade soil and base material, reducing the potential for pavement distress and rutting. Geotextiles also act as a separation barrier, preventing the intrusion of fines and water into the pavement layers, which can weaken the structure over time. Additionally, they distribute the load more evenly, improving the pavement's ability to withstand traffic loads and reducing the occurrence of cracks and potholes.

- Q: How do geotextiles contribute to the performance of geosynthetic tubes?

- Geotextiles play a crucial role in enhancing the performance of geosynthetic tubes by providing reinforcement, filtration, and separation functions. They help to distribute the stress and reduce the potential for puncture or tearing, thus improving the overall strength and stability of geosynthetic tubes. Additionally, geotextiles act as effective filters, preventing the migration of fine particles while allowing water or gases to pass through. This filtration capability helps maintain the integrity and functionality of the geosynthetic tubes. Finally, geotextiles aid in separating different materials or soil layers, preventing the mixing or contamination of materials and ensuring the optimal performance of geosynthetic tubes.

Send your message to us

Geotextil Y Geomembrana Non Woven Polypropylene Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords