Pre-painted steel coil offer from construction companies

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3254 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Brief of Product

Product Features

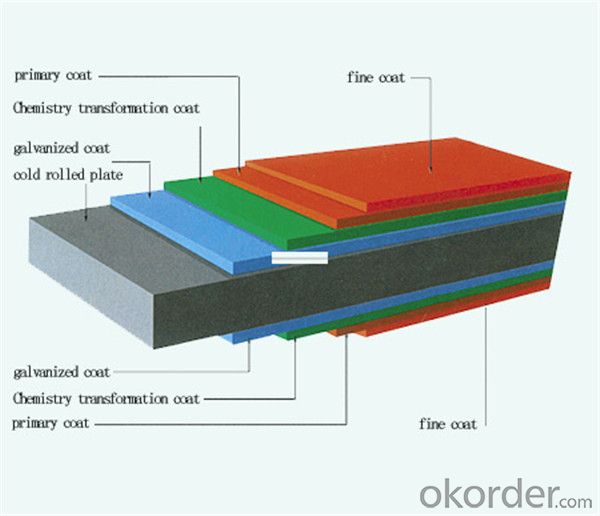

1 Extending service life of products:

Color coating is for protecting steel substrate and for promoting corrosion control effects. Subject to the environment, the different coating combination promotes environmental resisting functions (such as heat resistance, corrosion resistance, humidity resistance, bending resistance, weathering resistance, impact resistance, acid / alkali resistance, chemical resistance and pollution resistance) to offer ultra durability.

2 Better forming ability:

Colors

All types of colors available as per RAL codes mainly White, Red, Blue, Green, Cream, Orange and various others.

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

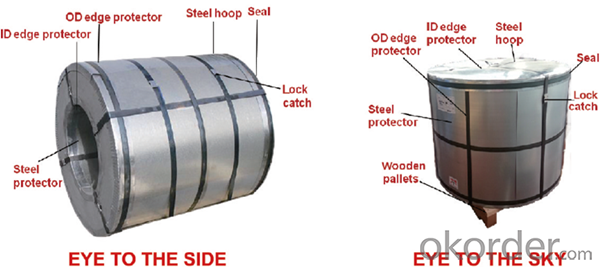

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our service

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: How are steel coils used in the production of steel rings?

- Steel coils are used in the production of steel rings by being shaped and cut into the desired dimensions. The coils are unrolled and passed through a series of machines that shape the steel into a circular shape. The steel is then cut to the required size and welded together to form the steel rings.

- Q: What are the different types of steel coil coatings available?

- There are several different types of steel coil coatings available, including galvanized, galvalume, and organic coatings. Galvanized coatings are made by dipping the steel coil in a bath of molten zinc, providing excellent corrosion resistance. Galvalume coatings, on the other hand, consist of a combination of aluminum and zinc, offering enhanced corrosion protection and heat resistance. Organic coatings, such as polyester, polyvinylidene fluoride (PVDF), and silicone-modified polyester (SMP), are applied to steel coils using a roll coating process, providing a wide range of color and aesthetic options, as well as additional protection against weathering and UV radiation.

- Q: At what temperature does steel start to warp or soften.

- Steel will only warp due to temperature under two conditions: 1. It is not heated evenly - in this case, the hotter parts will expand more than the cooler parts. 2. There are internal stresses in the steel (often from welding or cold-working - as an example, an I-beam or C-channel is usually hot worked, but some cold work can happen, so they can sometimes warp if you heat them ). This means that the steel won't warp due to temp if it's not 1 or 2. However, it could soften and fail if it has a load on it. As for softening, it really depends on what steel alloy you're looking at. Some steels (mainly the expensive alloys) don't really change until above 400 C (750 F), but mild steel really starts to weaken around 150-200 C (300-400 F) Rajashekhar has a point when it comes to forging. Steel isn't really soft enough to forge properly until above 1000C (1830 F), but if you're worried about using steel in a higher temp situation (like around a blast furnace or industrial oven), then make sure you choose a steel that has been rated to work at that temp.

- Q: What is the weight range of steel coils?

- The weight range of steel coils varies depending on the specific type and dimensions, but they generally range from a few hundred kilograms to several tonnes.

- Q: What are the different methods of coil leveling?

- Various industries commonly utilize several methods for coil leveling. These methods encompass: 1. Roller leveling: By passing the coil through a sequence of rollers, pressure is applied gradually, resulting in the gradual flattening of the coil. The rollers can be adjusted to exert varying levels of pressure, allowing for precise control over the leveling process. 2. Stretch leveling: This technique subjects the coil to tension forces, elongating the material and eliminating internal stresses. As the coil is stretched while passing through rollers, a more uniform and flat surface is achieved. 3. Temper leveling: Involving the heating of the coil to a specific temperature followed by rapid cooling, this method helps equalize stresses within the coil and enhance its flatness. Temper leveling is often employed for high-strength steels. 4. Roller leveling with leveling rolls: This approach utilizes additional leveling rolls placed above and below the main leveling rollers. These rolls apply pressure to specific areas of the coil, rectifying any unevenness or distortions. 5. Tension leveling: This method involves applying tension to the coil during processing. The tension aids in straightening and flattening the material, resulting in a more even and flat surface. 6. Precision leveling: Employed for high-precision applications necessitating extremely flat and uniform coils, precision leveling combines roller leveling, stretch leveling, and other corrective measures to attain the desired flatness. Each of these methods possesses unique advantages and limitations. The selection of a particular method depends on factors such as the type of material being leveled, the required flatness tolerance, and the intended application of the coil.

- Q: What is the maximum stacking height for steel coils?

- The maximum stacking height for steel coils depends on various factors such as the weight and size of the coils, the strength of the supporting structure, and the safety regulations and guidelines in place. It is recommended to consult the manufacturer's specifications and industry standards to determine the appropriate maximum stacking height for steel coils in a specific situation.

- Q: What are the common coil weight and width combinations available for steel coils?

- The industry or application dictates the available common weight and width combinations for steel coils. However, steel coils are commonly available in the following weight and width combinations: 1. Light gauge coils: These coils have a weight range of 5 to 10 tons and a width range of 600 to 1,500 mm. Industries such as automotive, construction, and appliances frequently use them. 2. Medium gauge coils: These coils have a weight range of 10 to 20 tons and a width range of 750 to 2,000 mm. They find applications in manufacturing, infrastructure, and engineering sectors. 3. Heavy gauge coils: These coils have a weight range of 20 to 35 tons and a width range of 900 to 2,200 mm. Industries that require thicker and wider steel sheets, like shipbuilding, oil and gas, and construction of large structures, commonly use them. 4. Narrow coils: These coils have a width range of less than 600 mm and can have varying weights based on specific requirements. Industries that need narrower strips of steel, such as automotive components, electrical appliances, and packaging, often use them. 5. Custom coil sizes: Manufacturers can provide custom sizes, besides the standard weight and width combinations mentioned above, to meet specific customer requirements. This allows for flexibility in meeting the unique needs of various industries. It is important to note that these weight and width combinations are not exhaustive and can vary depending on the steel manufacturer, production capabilities, and customer demands.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing moisture from coming into contact with the steel and causing corrosion. Additionally, the coils may be stored in a controlled environment with low humidity levels to further protect them.

- Q: I'm getting my nose pierced, meaning that i have to keep the piercing in for a prolonged time. i've always had reactions when wearing sterling silver or fake earrings (i dont know what types of metal they were) after wearing it overnight. Will I get a reaction on my nose piercing if the stud is surgical steel?

- Surgical Steel Tongue Rings

- Q: What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

Send your message to us

Pre-painted steel coil offer from construction companies

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3254 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords