Pre-painted Steel Coil for Galzed Tile Production

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

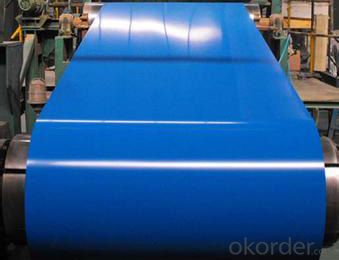

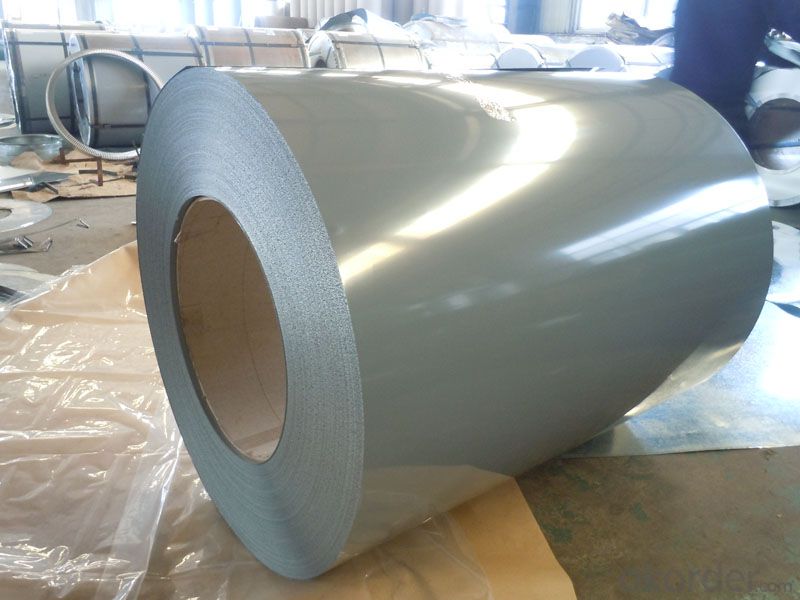

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan.

2.How to guarantee the quality of the products?

We have professional QC team.At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance 20% payment or original 100% LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Color steel sandwich panel foam per cubic meter of weight is how much

- Color steel sandwich board phenolic foam bulk density can reach about 50 kilograms per cubic meter

- Q: Can polyurethane sandwich panels be used for cold storage?

- Yes. Polyurethane cold storage board is a good insulation of lightweight polyurethane as the inner material, the external by the SII, PVC color steel plate and stainless steel plate made of polyurethane sandwich panels, the advantage of doing so is to prevent cold storage board because of the large temperature difference between inside and outside The temperature of the spread, so that the cold storage more energy-efficient, improve the efficiency of cold storage. Luoyang Tianjiang chemical production of polyurethane cold storage board also has fire, flame retardant and high temperature and other excellent features.

- Q: anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: I would like to build factories. Would like to ask the thickness of 10 cm under the foam sandwich board how much money a square.

- Only know the current price of foam board is 70 yuan a cubic (the lightest material), if coupled with the price of color steel, it is estimated that a flat price is more than ten dollars it Of course, the best choice of flame retardant, it should be more than 20 square.

- Q: Sandwich board is 50,75,100,150, color steel thickness, casually one can.

- 50 thick: 45 ~ 75 yuan 75 thick: 53 ~ 87 yuan 100 thick: 62 ~ 95. Sandwich panel thickness is not limited. I am also about this. Because you are not very clear.

- Q: Sandwich board room is suitable for long-term residence

- Yes Sandwich board activities room life 10 - - 15 years or so (ground waterproof well

- Q: Fire rock wool sandwich panels can continue to fire how much time

- Rock wool is a Class A fireproof material. Not burning

- Q: Color steel sandwich board board how to deal with bump

- After forming the basic no way, only to improve the process to solve

- Q: Foam sandwich board in line with the fire building requirements? There is no regulatory requirements in this area? I was in Jiangsu !! Thank you

- The new composite sheet is a new type of building material developed rapidly from five to ten years. These new building materials can meet the technical indexes of building structure, insulation and other related aspects, and have low cost, low investment, light weight, convenient construction, reusable Characteristics, has been the construction of the administrative departments of the strong recommendation, so in the construction has been widely used to form a social habit. As part of the composite plate refractory grade low and sandwich material is a macromolecule material with flammability, high smoke physical and chemical properties, once the fire, will distribute a large number of toxic flue gas and easy to collapse, fire fighting difficulties, easily lead to casualties. There have been a lot of such as the main building blocks as building blocks of building fires, and there are many major casualties of fire accidents, this year in Jiangsu Province, fire hazard investigation and management program as one of the key elements of investigation. Jiangsu Province Fire Brigade also issued a special notice to effectively strengthen the composite sheet in the construction of the application of fire supervision and management. This paper mainly discusses the use of composite plate, comprehensive performance comparison and the disaster situation in the fire, the application of the composite plate in the fire to explore the issue to help design units and owners of scientific selection, from the source to eliminate fire hazards.

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

Send your message to us

Pre-painted Steel Coil for Galzed Tile Production

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords