Pre-Painted Galvanized Steel Sheet/Coil in High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

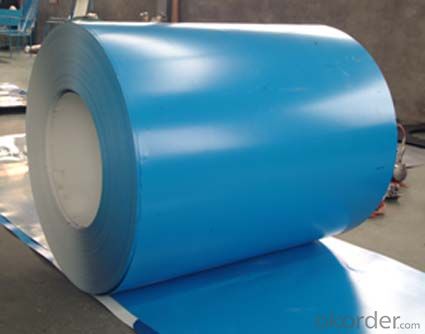

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How do you calculate the yield strength of a steel sheet?

- In order to determine the yield strength of a steel sheet, it is necessary to carry out a tensile test, which involves subjecting a sample of the steel sheet to stretching until it fractures. During this test, the stress and strain applied to the sample are measured. The yield strength denotes the point at which the material starts to deform plastically, meaning that it no longer returns to its original shape after the stress is removed. This mechanical property is of great importance as it indicates the maximum stress that the material can endure without undergoing permanent deformation. Throughout the tensile test, the stress applied to the steel sheet is measured as the strain on the sample is gradually increased. Stress is determined by dividing the force exerted on the sample by its initial cross-sectional area. Strain is calculated by dividing the change in length of the sample by its original length. The yield strength is defined as the stress at which a specific amount of permanent deformation occurs, typically 0.2% strain or 0.2% offset. In other words, the yield strength is the stress required to initiate a 0.2% alteration in the length of the sample. Once the stress-strain data is obtained from the tensile test, it is possible to plot a stress-strain curve. By locating the point on the curve where the stress corresponding to the specified amount of strain is reached, the yield strength can be determined. To summarize, to calculate the yield strength of a steel sheet, it is necessary to conduct a tensile test and measure the stress and strain applied to the sample. The yield strength is then determined by identifying the point on the stress-strain curve where a specific amount of permanent deformation occurs, indicating the maximum stress the steel sheet can withstand.

- Q: Can steel sheets be used in high-temperature environments?

- Yes, steel sheets can be used in high-temperature environments. Steel is known for its high strength and resistance to heat, making it a suitable material for applications that involve elevated temperatures. However, the specific type of steel and its composition should be considered to ensure it can withstand the desired temperature range without excessive deformation or deterioration.

- Q: Are the steel sheets heat-resistant?

- Yes, steel sheets are heat-resistant.

- Q: Are steel sheets resistant to impact or puncture?

- Yes, steel sheets are highly resistant to both impact and puncture due to their strong and sturdy nature.

- Q: Are the steel sheets suitable for high-temperature applications?

- Yes, steel sheets are generally suitable for high-temperature applications. Steel is known for its excellent strength and durability, making it a popular choice for various industries requiring materials that can withstand high temperatures. Steel sheets can be manufactured to have high melting points and can retain their structural integrity even under extreme heat. Additionally, steel has good thermal conductivity, allowing it to efficiently transfer heat away from the surface. However, it is important to consider the specific grade and composition of the steel sheets as some alloys are specifically designed for high-temperature applications. It is recommended to consult with a materials engineer or specialist to ensure that the steel sheets selected are suitable for the specific high-temperature environment.

- Q: What are the different profile options available for steel sheets?

- Some of the different profile options available for steel sheets include corrugated, ribbed, standing seam, trapezoidal, and flat profiles. These profiles are designed to offer various benefits such as enhanced strength, improved water drainage, and aesthetic appeal for different applications in construction and roofing.

- Q: Can steel sheets be used for automotive wheels?

- Yes, steel sheets can be used for automotive wheels. Steel wheels are commonly used in vehicles due to their durability and cost-effectiveness. However, it is important to note that steel wheels are typically heavier than other materials such as aluminum alloy, which may impact the vehicle's performance and fuel efficiency.

- Q: Can the steel sheets be used for metal stamping?

- Yes, steel sheets can be used for metal stamping. Steel is a commonly used material for metal stamping processes due to its durability and strength. The steel sheets are typically cut into specific shapes and sizes, and then undergo a stamping process where a die and punch set are used to form the desired shape on the steel sheet. This process can be used to create various products such as automotive parts, household appliances, and industrial components.

- Q: What are the environmental impacts of steel sheet production?

- The environmental impacts of steel sheet production include the extraction of raw materials such as iron ore, which can lead to deforestation and habitat destruction. The mining process also consumes large amounts of energy and water, contributing to greenhouse gas emissions and water pollution. Additionally, steel production involves the release of air pollutants, such as carbon dioxide, sulfur dioxide, and nitrogen oxides, contributing to climate change and air pollution. Waste generated during the production process, such as slag and dust, can also have negative impacts on soil and water quality if not properly managed.

- Q: Can steel sheets be used for construction formwork or molds?

- Yes, steel sheets can be used for construction formwork or molds, although they may not be as commonly used as other materials such as plywood or timber. Steel sheets are durable, strong, and can provide a smooth and even surface for casting concrete. They are particularly suitable for large-scale construction projects where formwork needs to withstand high pressures and loads. Steel sheets can be custom-designed and fabricated to meet specific project requirements, offering flexibility in shape, size, and configuration. However, it is important to consider the cost, weight, and availability of steel sheets compared to other formwork materials before making a decision.

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil in High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords