Pre-Painted Galvanized/Aluzinc Steel Sheet in Coil Royal Blue 0.25mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

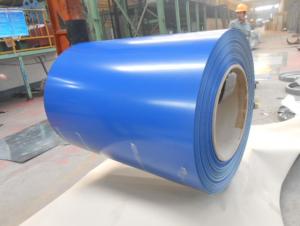

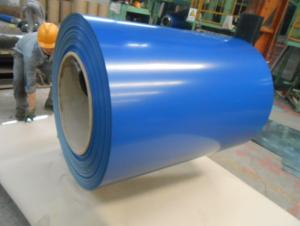

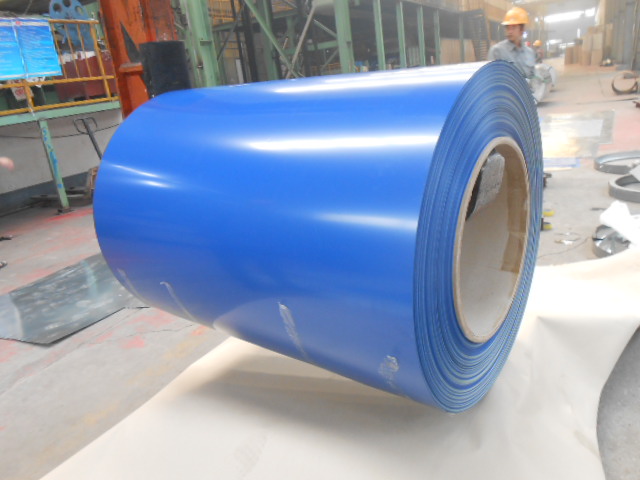

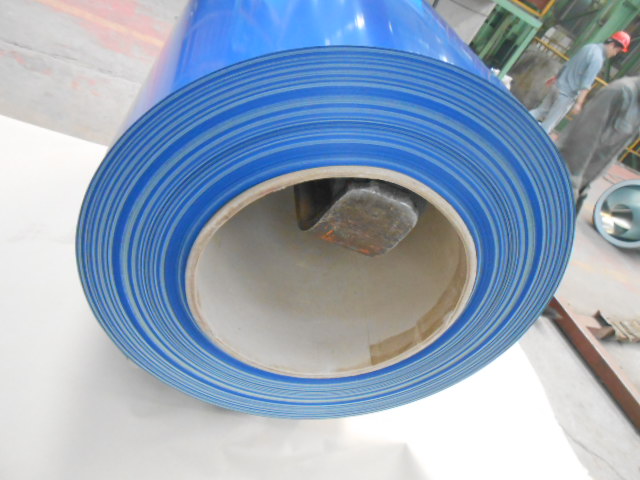

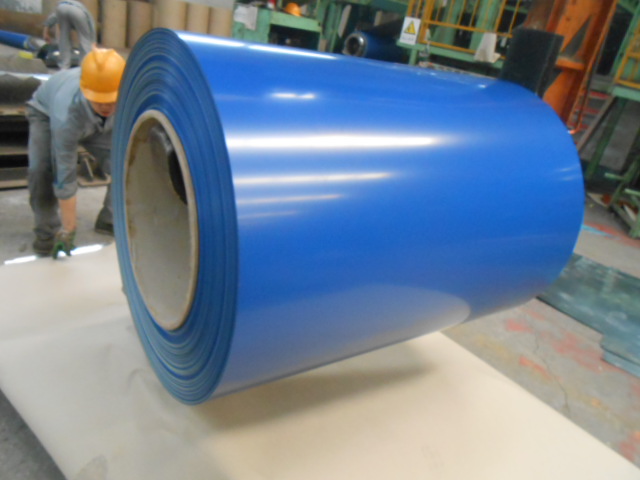

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of industrial filters?

- Steel coils are used in the manufacturing of industrial filters as a primary material for constructing the filter frames and support structures. The coils are typically cut, shaped, and welded to create the necessary framework that holds the filter media and allows for efficient filtration. The strength and durability of steel make it an ideal choice for withstanding the pressure and demands of industrial filtration processes.

- Q: What are the different coil coating options available for steel coils?

- There are several different coil coating options available for steel coils, each offering unique benefits and applications. 1. Polyester Coil Coating: Polyester coil coatings are the most commonly used option due to their affordability and versatility. These coatings provide good durability, weather resistance, and color retention, making them suitable for a wide range of indoor and outdoor applications. 2. Polyvinylidene Fluoride (PVDF) Coil Coating: PVDF coil coatings offer excellent resistance to fading, chalking, and chemical exposure. They are highly durable, making them ideal for exterior applications where long-term performance is required. PVDF coatings also have good dirt and stain resistance. 3. Polyurethane Coil Coating: Polyurethane coil coatings provide exceptional adhesion and flexibility. They are often used in applications where the steel coils require excellent resistance to abrasion, impact, and corrosion. Polyurethane coatings also offer good color retention and weather resistance. 4. Silicone Modified Polyester (SMP) Coil Coating: SMP coatings combine the benefits of polyester and silicone coatings. They offer enhanced resistance to chalking, fading, and industrial pollutants. SMP coatings are commonly used in agricultural, industrial, and architectural applications. 5. Polyvinyl Chloride (PVC) Coil Coating: PVC coil coatings provide excellent chemical resistance and are frequently used in applications where resistance to acids, alkalis, and solvents is critical. These coatings also offer good color retention and have a low environmental impact. 6. Epoxy Coil Coating: Epoxy coatings provide exceptional adhesion and corrosion resistance. They are often used in demanding environments such as marine or chemical processing industries. Epoxy coatings can be formulated to meet specific performance requirements, making them highly customizable. 7. Acrylic Coil Coating: Acrylic coatings offer excellent color retention, UV resistance, and gloss retention. They are commonly used in architectural applications where aesthetics are important. Acrylic coatings also provide good resistance to weathering and chemicals. It is important to consider the specific requirements of the application when choosing a coil coating option. Factors such as durability, weather resistance, chemical resistance, adhesion, and color retention should be taken into account to ensure the best performance and longevity of the steel coils.

- Q: What are the dimensions of steel coils used in the transportation equipment industry?

- The dimensions of steel coils utilized in the transportation equipment sector may differ according to specific demands and applications. Nevertheless, there exist some prevalent measurements that are extensively employed. Typically, the width of steel coils used in the transportation equipment industry ranges from 600mm to 2000mm (24 to 78 inches). This width is selected to ensure compatibility with the machinery and equipment employed in transportation, such as trucks, trailers, and railcars. The thickness of steel coils exhibits significant variation depending on the specific application and desired material strength. However, common thickness ranges for steel coils in the transportation equipment industry generally fall between 0.5mm and 6mm (0.02 to 0.24 inches). The inner diameter of steel coils utilized in the transportation equipment industry is typically standardized at either 508mm (20 inches) or 610mm (24 inches). This standardization facilitates easy handling and compatibility with industry machinery. The outer diameter of steel coils can differ depending on the coil's width and thickness. Nonetheless, typical outer diameter ranges for steel coils in the transportation equipment industry generally span from 1000mm to 2200mm (39 to 87 inches). It should be recognized that these dimensions are not fixed and can be tailored to specific requirements and applications within the transportation equipment industry.

- Q: Is cold steel actually steel? Does it hurt? Why is it used in training? First one to goodly answer those questions gets 10 points.

- Cold steel was an expression originally used to signify a sword. From feeling the cold of the blade as it entered the body.

- Q: I just want to know why is cold steel katana a very good sword?? How can you tell if a cold steel katana is good or not

- Save your money and by a wooden boken. Train with a well balanced wooden one. It is how the great Japanese master started their training. Steel swords are good for display. and perhaps if you become relay good and want to feel the heft and practice cutting straw men and bamboo stalks than invest some money in the real deal for a few hundred $$ at the least.

- Q: I have a tiara and it oxidized and I'm not sure what material it is. I know it it isn't metal so i was wondering if is steel? Also if it's steel, can I do something to clean it?

- Yes - Steel can oxidize, its most commonly called rust Steel is a metal. Depending on the level of oxidation, you might be able to polish it with very fine steel wool. If is is really bad, then you might need a chemical cleaner such as Naval Jelly, which can be found at the hardware store. But the Naval Jelly might discolor the metal, so then you might need to polish it afterward to return its finish.

- Q: How are steel coils used in the manufacturing of appliances?

- Steel coils are used in the manufacturing of appliances as they are transformed into various components such as frames, panels, and inner structures. These coils are processed and shaped through cutting, bending, and stamping techniques to create the necessary parts, ensuring durability and strength in the final product.

- Q: What are the common applications of cold-rolled stainless steel coils?

- Cold-rolled stainless steel coils are widely used in various industries due to their unique characteristics and versatility. Some common applications of these coils include: 1. Automotive Industry: Cold-rolled stainless steel coils are used in the automotive industry for manufacturing parts such as exhaust systems, trim, and body panels. The high corrosion resistance and aesthetic appeal of stainless steel make it an ideal choice for these applications. 2. Construction Industry: Stainless steel coils are extensively used in the construction industry for roofing, cladding, and structural components. The durability, strength, and resistance to corrosion make cold-rolled stainless steel coils a preferred material in buildings, bridges, and other infrastructure projects. 3. Kitchen Appliances: Stainless steel coils are commonly used in the production of kitchen appliances such as refrigerators, ovens, and dishwashers. The hygienic properties, easy maintenance, and sleek appearance of stainless steel make it a popular choice for these applications. 4. Food Processing Industry: Cold-rolled stainless steel coils find extensive use in the food processing industry due to their non-reactive nature and resistance to corrosion. These coils are used for manufacturing equipment, storage tanks, and conveyor systems in food processing plants. 5. Medical Equipment: Stainless steel coils are widely used in the medical industry for manufacturing surgical instruments, implants, and medical devices. The biocompatibility, strength, and resistance to corrosion of stainless steel make it suitable for these critical applications. 6. Oil and Gas Industry: Cold-rolled stainless steel coils are used in the oil and gas industry for various applications, including pipelines, storage tanks, and offshore platforms. The high resistance to corrosion and extreme temperature conditions make stainless steel a reliable choice in this demanding industry. 7. Aerospace Industry: Stainless steel coils are employed in the aerospace industry for manufacturing aircraft components, engine parts, and structural elements. The lightweight yet high-strength properties of stainless steel make it an ideal material for these applications. Overall, the common applications of cold-rolled stainless steel coils span across diverse industries, including automotive, construction, kitchen appliances, food processing, medical, oil and gas, and aerospace. The unique combination of durability, corrosion resistance, strength, and aesthetic appeal make stainless steel coils a preferred choice in various industrial sectors.

- Q: How are steel coils protected from mechanical damage?

- Steel coils are typically protected from mechanical damage through the use of various packaging materials such as wooden crates, steel frames, or protective plastic wraps. These measures ensure that the coils remain intact and safeguarded during transportation, handling, and storage, minimizing the risk of any potential mechanical damage.

- Q: How are steel coils used in the production of storage tanks?

- Steel coils are typically used as the raw material in the production of storage tanks. These coils are formed into sheets and then shaped and welded to create the tank's body. The strength and durability of steel make it an ideal choice for storing various substances, including liquids and gases, ensuring the safety and longevity of the storage tanks.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Sheet in Coil Royal Blue 0.25mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords