Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. 2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• High strength

• Good formability

• Good visual effect

• C

apability of decoration, molding, corrosion resistance• Workability, durability

• Excellent heat resistance performance

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

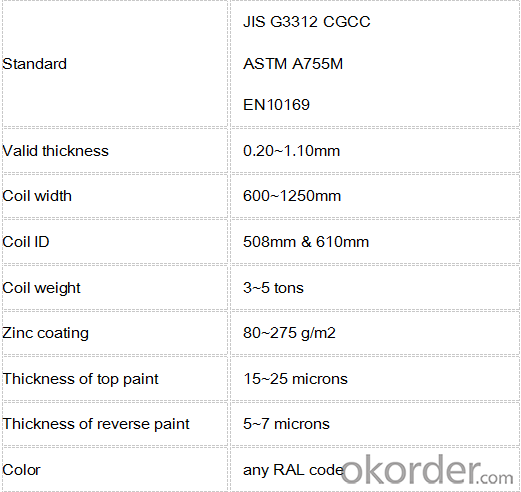

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I need to know which cookware set is better. We are trying to get rid of the ones we have here. They are Teflon. I have heard that stainless steel (aluminum) and hard Ionized are good, but which is the best one.

- Hard anodized generally refers to aluminum that has had a specific surface treatment. The benefit of aluminum is that it's a better conductor of heat than stainless, so it will heat up faster, depending on thickness. It's also lighter than steel, if that matters to you. As far as stainless steel, it all depends on the quality of the steel and of the construction. Some pots and pans are made from cheap grades of stainless which can suffer from corrosion problems. Though this shouldn't affect the taste of the food, only the appearance of the pan. Companies making bargain products may also skimp on materials by making the metal thinner; this causes hot-spots when cooking, In the case of skillets, thinner materials are more likely to warp over time. Stainless steel is generally stronger and tougher than aluminum- less likely to dent. Thought again, strength also depends on thickness. A good quality stainless pan is hard to beat in terms of durability, these things can last several lifetimes. On the other hand so will a good quality aluminum one.

- Q: Looking for a new entry door for my home If someone would explain the features and benefits of both fiberglass and steel doors I would greatly appreciate it!!

- Steel doors can dent easily and are usually cheaper in price. Whereas fiberglass doors cost more but are more durable to withstand weather etc. Steel doors show the effects of wear and tear more than wood or fiberglass doors do.

- Q: I need the measurements of the height and hypotenuse of the first drop in the Steel Dragon 2000. I couldn't find it anywhere. It would be great if you could also show me the website where you got your answer. Thanks! =]*The hypotenuse is the length of the drop.*

- Steel Dragon 2000 is a roller coaster at Nagashima Spa Land Amusement Park in Mie Prefecture, Japan. Built by Morgan Manufacturing, this gigacoaster opened, appropriately, in 2000 - The Year of the Dragon in the Far East. It debuted only months after Millennium Force and surpassed the Cedar Point coaster as the world's tallest complete-circuit coaster. It also set a record for longest track length - 8133 feet, 2 inches (2479 m), which it currently holds. Coaster Facts * Steel Dragon 2000 is the tallest coaster to utilize a traditional chain lift. Because of the length of the lift hill, two chains are used - one for the bottom half and one for the top half. A single chain would have been excessively long and heavy, at least twice the weight of one of the trains. As a result, two trains can safely occupy the lift simultaneously. * The building of Steel Dragon 2000 required far more steel than other coasters for earthquake protection. This put the cost of the coaster at over $50,000,000. * On August 23, 2003, Steel Dragon 2000 was involved in an accident during a run in which one of its trains lost a wheel. The coaster did not operate during the 2004 and 2005 park seasons. It reopened September 3, 2006.

- Q: Ik iron was too heavy but could steel bolts have been used. I can see iron dissolving at surface when to be a danger it needs to reach the core of sun.. But so does steel go deeper in(w.e alloy turned from iron)..I wanna know which would be worse iron..or upgraded iron(steel) and if the steel would have worse effects than normal iron..Im sure if we used iron we used steel

- Steel might have been used in some bolts sure. But.....are you under the impression that Ulysses was ever intended to crash into the Sun or something? You know it wasn't right? It was launched (in the 1980's) to study the Sun. But....uh.....not by crashing into it. Ulysses was even sent out to use Jupiter as a gravitational assist. We are closer to the Sun than Ulysses is..... Even if it did go crash into the Sun though there is absolutely no way that ANY material, natural or manmade, could survive intact all the way to the core of a star. It takes photons of LIGHT something like 100,000 years just to make it out from the core of the Sun to the surface because it is so dense. How do you propose a metal probe making it back the other way? Would it have worse effects than what? The effects, no matter what it was made out of, would be that as it got CLOSE to the Sun it would vaporize. No matter what it was made out of though it would have no affect whatsoever on the Sun. Every single element, without exception, that exists on the Earth and everywhere else in our solar system also exists in the Sun already, in far greater quantities. The planets and Sun all formed out of the same nebula at the same time. The Sun just got massive enough that fusion began and it became a star. There is already more iron in the Sun than there is everything on Earth. If you took every single atom of every element there is on the Earth it would still not add up to even a fraction of the total amount of iron in the Sun.

- Q: pros and cons of stainless steel and carbon steel swords

- Carbon is what samurais added to their swords to make them super strong. The iron ore was cooked in coal for days; the coal adds the carbon. Too much carbon or too little carbon is a bad thing so it was a very important process. I'd have to go with a sword with carbon.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. Steel is a highly recyclable material, and steel coils can be melted down and used to produce new steel products. Recycling steel coils not only helps to conserve resources and reduce waste but also contributes to a more sustainable and environmentally-friendly manufacturing process.

- Q: Can steel coils be galvanized?

- Yes, steel coils can be galvanized. Galvanization is a process of applying a protective zinc coating to steel to prevent corrosion. Steel coils are often galvanized to increase their durability and resistance to rust.

- Q: I have a knife with AUS8 Stainless Steel. No idea what that means. I want to know some of the best stainless steels for knifes and all you can tell me about stainless steel would be great. I was browsing google and looking at grades and had no idea what all the numbers meant. Thanks!

- Ok so listen she already likes me what should I say

- Q: How are steel coils used in the production of storage systems?

- Steel coils are used in the production of storage systems as they are rolled into sheets and then formed into various components such as shelves, frames, and brackets. These components are then assembled to create sturdy and durable storage systems that can hold and organize various items efficiently.

- Q: How do steel coils perform in corrosive environments?

- Steel coils exhibit excellent performance in corrosive environments due to their inherent resistance to corrosion. This is primarily because steel, being composed of iron and various elements like carbon, produces a protective layer called a passive film. This passive film acts as a barrier between the steel surface and corrosive elements, effectively preventing direct contact and minimizing the risk of corrosion. Moreover, steel coils can be coated with different protective coatings to enhance their corrosion resistance. Coatings like zinc or epoxy provide an additional layer of protection, significantly prolonging the lifespan of steel coils in corrosive environments. However, it is important to acknowledge that the performance of steel coils in corrosive environments can still be influenced by factors such as the type of corrosive agent, duration of exposure, and presence of other contaminants. In highly aggressive environments, such as those with high humidity, exposure to saltwater, or acidic chemicals, the protective layers on steel coils might deteriorate over time, thereby increasing the potential for corrosion. To ensure optimal performance in corrosive environments, it is advisable to choose steel coils with corrosion-resistant properties, such as stainless steel or galvanized steel. Regular maintenance and inspections are also crucial to promptly detect any signs of corrosion and implement appropriate measures to prevent further damage. In conclusion, steel coils generally exhibit good resistance to corrosion in most environments, but the severity of the corrosive conditions can ultimately impact their performance.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords