Pre-Painted Galvanized/Aluzinc Steel Coil --Smooth and Flat Surface

- Loading Port:

- China main port

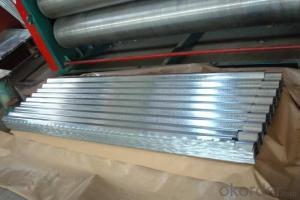

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil --Smooth and Flat Surface

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of Pre-Painted Galvanized/Aluzinc Steel Coil --Smooth and Flat Surface:

• Excellent process capability

• Smooth and flat surface

• High strength

3. Images:

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Special Use: High-strength Steel Plate

Width: 20-1250mm

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

coil weight: 4-7 tons

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of edge treatments for steel coils?

- Steel coils can undergo different edge treatments, each serving a specific purpose and offering unique benefits. 1. The most commonly used edge treatment is the slit edge. This involves cutting the coil along its width, resulting in two distinct edges. Slit edges are usually smooth and free from burrs, making them suitable for most applications. 2. The mill edge is the untreated edge of a steel coil straight from the rolling mill. It has a rough and uneven surface with visible imperfections like burrs and irregularities. Mill edges are generally not suitable for direct use and require further processing or trimming to achieve the desired edge quality. 3. The trimmed edge is a treatment that involves removing the rough and irregular portions of the mill edge. This is done through shearing or cutting, resulting in a smoother and more consistent edge. Trimmed edges are commonly used when a clean and uniform appearance is required. 4. Deburred edge refers to the process of removing any sharp or rough edges from the steel coil. This treatment is crucial for applications where safety is a concern as it eliminates the risk of injuries from handling sharp edges. Deburred edges are achieved through grinding or filing and provide a smooth and safe edge for various applications. 5. Rounded edge is a treatment that involves rounding the sharp corners of the steel coil. This is done to prevent damage to other materials or surfaces during handling or transportation. Rounded edges reduce the risk of scratches, dents, or other forms of surface damage. 6. Beveled edge is a treatment where the edge of the steel coil is cut at an angle, typically 45 degrees. This treatment is commonly used in applications that require a tight fit or seamless joint with other components. Beveled edges allow for easier assembly and improve the overall appearance of the final product. Each of these edge treatments offers its own advantages and is chosen based on the specific requirements of the application. Choosing the right edge treatment for steel coils is crucial to ensure optimal performance, safety, and aesthetics in industries such as construction, manufacturing, automotive, and more.

- Q: What are the industries that consume the most steel?

- I'm guessing manufacturing

- Q: What is the shear modulus of steel and silver? Please help! and state where you got it from...what site did you used? Thanks.

- Modulus Of Rigidity Of Steel

- Q: I recently got in a car accident with a steel mailbox, on a snowy day. I was wondering if i can do anything since the steel mailbox caused my car to be totaled. Otherwise it would have been fine and would have suffered only minor damage. Anything I can do here to maybe get some money back? Thanks!

- The steel mailbox caused my car to be totaled? How did it do that? Did the mail box fail to stop at the stop sign? Did it rear end you when you stopped at the red light? Was the mail box under the influence of drugs or alcohol at the time of the accident? Or, would a more accurate way of putting it is you failed to take weather conditions into account and totaled your car by hitting a mail box? Stop blaming the innocent mail box.

- Q: How are steel coils used in the production of kitchen appliances?

- Steel coils are used in the production of kitchen appliances as they are transformed into various components such as panels, frames, and structural elements. These coils are typically cut, shaped, and formed to create the necessary parts for appliances like refrigerators, ovens, and dishwashers. The high strength and durability of steel make it an ideal material for these appliances, ensuring their longevity and reliability.

- Q: How long do steel coils last?

- The durability of steel coils can differ based on different elements, including the steel's quality, the storage or usage conditions, and the specific application. Typically, top-notch steel coils can endure for numerous years or even decades before exhibiting any signs of deterioration or wear. Nevertheless, it is essential to acknowledge that if steel coils are not adequately maintained or shielded from moisture or harsh surroundings, they can be prone to corrosion. Consequently, consistent inspection, maintenance, and appropriate storage or usage methods play a pivotal role in optimizing the lifespan of steel coils.

- Q: What is future prospect of these steel structures, are they really weather proof like everyone believes??

- you are doubting the steel structure building? Well, not every compay can give the same steel building, come to Muyang, it can give you best steel structure building.

- Q: What are the different coil edge options?

- The different coil edge options include open coil, continuous coil, offset coil, and pocket coil.

- Q: What are the different methods of coil flattening for steel coils?

- There are several methods of coil flattening for steel coils, each with its own advantages and limitations. Some of the most commonly used methods include: 1. Roller leveling: This method involves passing the steel coil through a series of rollers that apply pressure to flatten the coil. The rollers can be adjustable to achieve the desired level of flatness. Roller leveling is a versatile method that can handle a wide range of coil sizes and thicknesses. 2. Precision leveling: This method utilizes a more sophisticated leveling machine that applies pressure on specific areas of the coil to eliminate any waviness or defects. Precision leveling is often used for high-quality steel coils that require extremely flat surfaces. 3. Stretch leveling: Also known as tension leveling, this method involves stretching the steel coil beyond its yield point, causing it to permanently deform and flatten. Stretch leveling is commonly used for thinner gauge coils and can effectively remove coil set and crossbow defects. 4. Temper rolling: This method involves subjecting the steel coil to a controlled low-temperature heat treatment followed by cold rolling. The combination of heat and cold rolling helps to relieve internal stresses and improve flatness. Temper rolling is particularly suitable for coils that require enhanced surface quality. 5. Laser flattening: This advanced method utilizes laser technology to selectively heat and flatten specific areas of the coil. Laser flattening is highly precise and can correct localized defects or unevenness, but it is typically used for smaller coils due to its higher cost. It is important to note that the selection of the most appropriate method for coil flattening depends on various factors, including the desired flatness requirements, coil dimensions, material properties, and production budget.

- Q: I know that the steel is significantly harder than when air cooled, but why is the quenched steel harder?

- When steel is slowly cooled, lots of carbon diffusion takes place because it is not very soluble in steel at room temperature. The carbon is in solution at high temperatures, and is rejected out of the lattice as it cools. And when this happens, the microstructure will consist of ferrite and pearlite, and the lattice structure will be base centered cubic (bcc). If it is cooled fast enough, then the carbon gets trapped in the interstitial sites of the lattice and distorts it to a body centered tetragonal (same as bcc, but elongated in one direction) This elongation strains the lattice and makes it harder. Also, when cooled fast enough the atoms do not have time to diffuse like they normally would and they shear into place. This forms the hard phase of martensite that is desired of heat treated steel. But then it must be tempered back some because it is too brittle.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil --Smooth and Flat Surface

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords