PPGI Steel Sheet Coil with Nice Quality and Lowest Price Blue

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 123 m.t.

- Supply Capability:

- 11111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

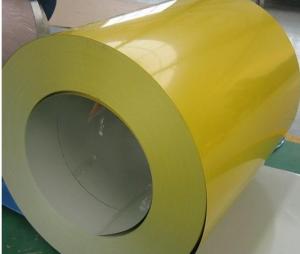

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, PPGI steel is good capable of decoration, molding, corrosion resistance.

It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• High strength

• good corrosion resistance

• perfect weather resistance

• Good formability

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

8Zinc coating: 60-275G/M2, both sides

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: why do you need to heat steel when hardening, molecules etc etc

- Halps is off base a little. The reason heat is involved in hardening of steels depends, a little bit, on how you are doing the hardening. If you are hardening by work hardening, you do not have to heat it at all. If you are barbarizing (case hardening), the temperature is raised to increase the diffusion rate of carbon into the steel, higher C content - higher hardness. If you are Thur hardening, you have to heat the steel to the austenitizing temperature (so the structure transforms to FCC crystals with higher solubility for C) and then quench it (cool it rapidly enough to freeze the C atoms in the martensite crystal structure). If you slow cool, the steel could end up softer than it started. All of these processes involve atomic level things. If you want to understand them on the atomic level, you need to study physical metallurgy of steels. It is a subject onto itself and is really quite fascinating if you are interested.

- Q: What are the common uses of pre-painted steel coils?

- Pre-painted steel coils are commonly used in various industries such as construction, automotive, and appliances. They are utilized for manufacturing roofing and wall panels, garage doors, ductwork, and other building components. In the automotive sector, pre-painted steel coils are employed to produce body panels, trims, and other exterior parts. Additionally, they find applications in the manufacturing of household appliances like refrigerators, washing machines, and ovens.

- Q: How are steel coils used in the manufacturing of electrical appliances?

- Steel coils are commonly used in the manufacturing of electrical appliances as they serve as the core component in the production of electromagnets. These electromagnets are used in various applications such as motors, transformers, and solenoids, allowing for the conversion of electrical energy into mechanical energy or vice versa. The steel coils provide the necessary magnetic properties and high conductivity required for efficient operation in electrical appliances.

- Q: What are the common methods of protecting steel coils from corrosion during storage?

- To safeguard steel coils from corrosion during storage, there are multiple commonly employed techniques. These methods aim to shield the steel coils from moisture and other environmental factors that could trigger corrosion. 1. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging is extensively utilized for steel coil protection. It incorporates VCI materials into the packaging, such as plastic bags or films. These materials emit a vapor that forms a protective layer on the surface of the steel coils, effectively preventing the intrusion of moisture and corrosive agents. 2. Oil Coating: Another widely adopted approach involves applying a thin layer of oil onto the steel coil surface. This oil acts as a barrier, obstructing the contact between the steel and moisture or oxygen. It proves particularly effective for long-term storage or transportation situations. 3. Desiccants: Silica gel packets or similar desiccants can be placed inside the packaging to absorb any trapped moisture. By reducing humidity levels within the packaging, the risk of corrosion is minimized. This method is often combined with VCI packaging or oil coating. 4. Proper Ventilation: Adequate ventilation is crucial to prevent moisture buildup around the steel coils during storage. By facilitating the free circulation of air, humidity levels are reduced, and the formation of condensation, which can lead to corrosion, is prevented. 5. Controlled Environment: Storing steel coils in a controlled environment is an effective corrosion prevention measure. This entails maintaining constant temperature and humidity levels that are unfavorable for corrosion. Temperature and humidity control can be achieved using air conditioning or dehumidification systems. It should be noted that the choice of specific protection methods or combinations thereof depends on various factors, including storage duration, environmental conditions, and specific steel coil requirements. Regular inspections and maintenance are also vital to ensure ongoing corrosion protection.

- Q: What is the maximum stacking height for steel coils?

- The maximum stacking height for steel coils depends on several factors, including the weight and dimensions of the coils, as well as the storage facility's structural capacity. Generally, it is recommended to consult the manufacturer's guidelines or industry standards to determine the specific maximum stacking height for steel coils.

- Q: How are steel coils used in the production of automotive body panels?

- Steel coils are used in the production of automotive body panels by being processed and shaped into the desired form through techniques like stamping, cutting, and bending. These coils provide the necessary strength and durability required for the structural integrity of the body panels, ensuring the safety and performance of the vehicle.

- Q: How do steel coils contribute to the aerospace industry?

- Steel coils contribute to the aerospace industry by being used in the manufacturing of various aircraft components such as engine parts, landing gear, and structural elements. The high strength and durability of steel make it a preferred material for these applications, ensuring the safety and reliability of aircraft. Additionally, steel coils are also used in the production of specialized tools and equipment required for aerospace manufacturing processes.

- Q: so my parents gave me stainless steel cookware for christmas and the first time i used it i cooked chicken. it stuck to the pan and where the oil splattered it cooked on and turned it dark black and brownish. and the bottom too. i don't cook with it because i don't want to burn it on anymore but i don't know how to clean it. how do i cook without burning anything, aside from a lower flame and how on earth do i get the stains on. i've tried almost everything too! thanks.

- Use oven cleaner. It will take off the burnt on stuff just like it does in the oven. Spray it on, put the cover on the pot and let it sit for a while. If the problem is on the outside, do the same but put the whole thing in a garbage bag to control the fumes. Wash the pot like you would normally to get the oven cleaner off. You will want to wear gloves too. Oven cleaner is very caustic. By the time you realize you are being burned by it, it's too late. The oven cleaner should do nothing to the finish of the stainless.

- Q: What website can I use to find a good picture that shows the atomic structure of a carbon steel?

- Carbon steel is a polycrystalline substance containing several compounds. Most of it is iron, but there are crystals of austenite and martensite present, plus other iron carbides. Each of these has a different atomic structure. The properties of the steel depend not so much on the atomic structures of the compounds, but more on the size and abundance of the crystals. The function of these crystals is to impede the movements of dislocations through the iron.

- Q: What are the cost considerations when purchasing steel coils?

- When purchasing steel coils, there are several cost considerations that need to be taken into account. Firstly, the price per unit of steel coil is a significant factor. The cost of steel coils can vary depending on various factors such as the type of steel, its grade, thickness, width, and length. Higher-grade steel coils tend to be more expensive than lower-grade ones, and thicker or wider coils can also come at a higher cost. Another cost consideration is the quantity of steel coils needed. Purchasing larger quantities of steel coils often comes with volume discounts, so it is important to determine the required quantity and assess whether it is more cost-effective to buy in bulk or in smaller batches based on the demand and storage capacity. Transportation costs should also be considered when purchasing steel coils. The weight and size of the coils can impact the shipping costs, especially if they need to be transported over long distances. Additionally, the distance between the supplier and the buyer can affect freight charges, so it is crucial to evaluate different shipping options and choose the most cost-effective method. Furthermore, it is essential to take into account any additional costs associated with processing or customizing the steel coils. For instance, if the coils need to be cut, leveled, or coated, these additional services can add to the overall cost. It is important to obtain quotes from different suppliers and compare the prices for these value-added services. Lastly, it is crucial to consider the overall quality and reliability of the steel coils. While cheaper options may initially seem more cost-effective, they could end up costing more in the long run if they do not meet the required standards or have a shorter lifespan. It is advisable to choose reputable suppliers with a track record of delivering high-quality products to ensure that the investment in steel coils is worthwhile. In conclusion, the cost considerations when purchasing steel coils include the price per unit, quantity discounts, transportation costs, additional processing services, and the overall quality and reliability of the coils. Evaluating these factors thoroughly will help make an informed decision that balances cost-effectiveness with the desired quality and specifications of the steel coils.

Send your message to us

PPGI Steel Sheet Coil with Nice Quality and Lowest Price Blue

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 123 m.t.

- Supply Capability:

- 11111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords