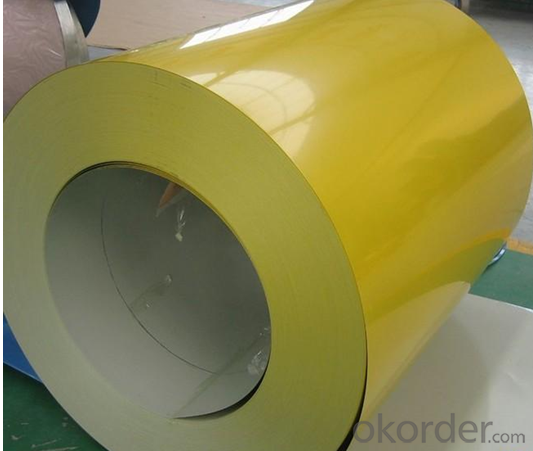

PPGI,Pre-Painted Steel Coil/Sheet with Prime Quality Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils secured during transportation?

- Steel coils are typically secured during transportation using steel strapping, bands, or wire rope. These securements help prevent the coils from shifting or falling off the transportation vehicle, ensuring their safe delivery to the destination.

- Q: How are steel coils used in the production of kitchen appliances?

- Steel coils are used in the production of kitchen appliances as they are transformed into various components such as panels, doors, and frames. These coils are typically cut, shaped, and welded into desired forms, providing strength, durability, and a sleek finish to the appliances.

- Q: Steel used to be made in the #92;Bessemer Converter, write about how steel making processes today produce better quality steel????

- how we can prepared steel by using converter? ans it

- Q: What are the different methods of engraving steel coils?

- There are several methods of engraving steel coils, including laser engraving, chemical etching, mechanical engraving, and electrochemical etching. Each method involves different techniques and tools to create precise and permanent markings on the surface of the steel coils.

- Q: Yes, I understand it can weaken steel greatly. But can it MELT steel? (key word: melt)

- Not likely -- the melting point of steel is about 1500 degrees Celsius, while the hottest jet fuel burns at is about 825 degrees Celsius (and its usually way below that). If you're one of those people wondering why the collapse in 9/11 ... it's quite possible that the temperatures and heat inside the buildings were way about the melting point of steel in some places. But it would not be just because of burning jet fuel. And, planes carry a lot of material that can catch fire at relatively low temperatures, but which can give off a huge amount of heat (and reach high temperatures), which would contribute to melting and burning of mild steel.

- Q: How are steel coils used in the manufacturing of agricultural trailers?

- Steel coils are used in the manufacturing of agricultural trailers to provide strength, durability, and stability to the trailer's frame, ensuring it can withstand heavy loads and harsh working conditions. These coils are typically shaped and welded to create the trailer's structural components, such as the chassis, sidewalls, and flooring. Additionally, steel coils can be cut and formed into various parts, including axles, suspension systems, and hitch assemblies, to further enhance the trailer's performance and functionality in agricultural operations.

- Q: What are the dimensions of steel coils used in the transportation equipment industry?

- The dimensions of steel coils used in the transportation equipment industry can vary depending on the specific application and manufacturer. However, commonly used dimensions range from 0.015 inches to 0.625 inches in thickness and from 24 inches to 60 inches in width. The outer diameter of these coils typically falls within the range of 48 inches to 72 inches.

- Q: How are steel coils used in the manufacturing of roofing materials?

- Steel coils are used in the manufacturing of roofing materials as they are rolled into sheets or formed into various shapes to create durable and long-lasting roofing products. The coils are processed through machines that cut, bend, and shape them into the desired dimensions and profiles required for different types of roofs.

- Q: What are the environmental impacts of steel coil production?

- The environmental impacts of steel coil production include the extraction of raw materials, such as iron ore and coal, which can lead to deforestation, habitat destruction, and soil erosion. The steel manufacturing process also releases significant amounts of greenhouse gases, such as carbon dioxide, contributing to climate change. Additionally, the production of steel coils requires large amounts of water and energy, leading to water scarcity and increased carbon emissions.

- Q: What is the use for spring steel that take advantage of its unique properties?

- The primary use is for springs. It can be deflected to a large extent by applying a force it will return to its original shape when the force is removed. The force/displacement relationship tends to be a constant. A lesser use is to use spring steel wire as a vibrating string on a stringed instrument.

Send your message to us

PPGI,Pre-Painted Steel Coil/Sheet with Prime Quality Yellow Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords