PPGI Color Coated Galvanized/Aluzinc Steel Sheet in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

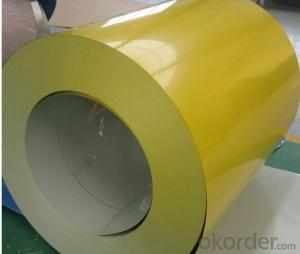

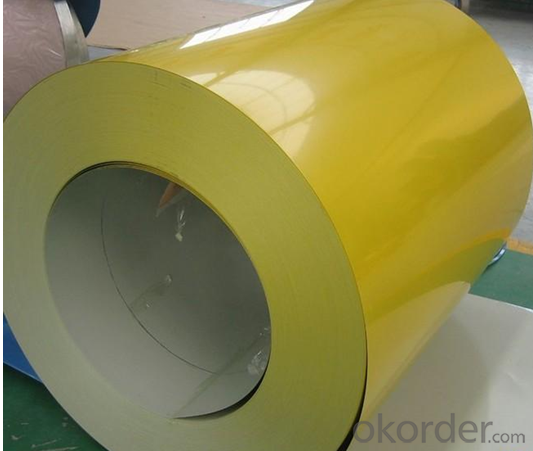

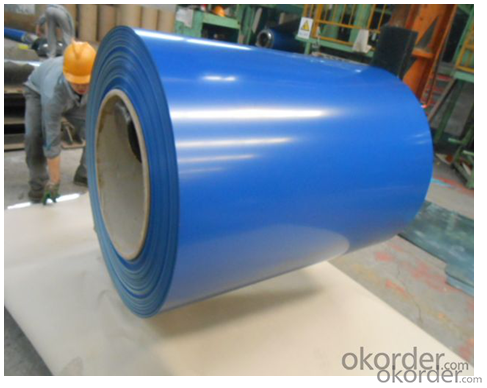

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How does the thickness of a steel coil affect its applications?

- The thickness of a steel coil has a significant impact on its applications. The thickness determines the strength, durability, and versatility of the steel, making it suitable for various uses across different industries. In applications where strength is crucial, such as the construction industry, thicker steel coils are preferred. Thicker coils provide higher structural integrity and load-bearing capacity, which is essential in buildings, bridges, and infrastructure projects. Thicker steel coils also offer better resistance to bending, warping, and other forms of deformation, making them ideal for heavy-duty applications. The thickness of a steel coil also affects its durability. Thicker coils have a higher resistance to wear, corrosion, and damage, making them suitable for harsh environments or applications that involve constant friction or exposure to elements. For example, thicker steel coils are commonly used in manufacturing heavy machinery, automotive parts, and mining equipment, where durability is paramount. Furthermore, the thickness of a steel coil determines its versatility and adaptability. Thinner coils can be easily formed into different shapes and sizes, making them suitable for applications that require intricate designs or tight tolerances. Industries such as automotive, aerospace, and consumer electronics often rely on thinner steel coils for their lightweight and flexible nature. On the other hand, thicker steel coils may limit the range of applications due to their weight and reduced flexibility. They are more suitable for applications that prioritize strength and durability over versatility. These applications include structural components, large-scale machinery, and industrial equipment. In summary, the thickness of a steel coil plays a crucial role in determining its applications. Thicker coils offer increased strength, durability, and resistance, making them ideal for heavy-duty applications in construction and manufacturing industries. Thinner coils, on the other hand, provide versatility and adaptability, making them suitable for applications that require intricate designs or lightweight properties.

- Q: What is the role of steel coils in the production of storage shelves?

- Steel coils play a crucial role in the production of storage shelves as they are used as the primary material to create the structural components of the shelves. These coils are flattened, cut, and formed into various shapes and sizes to construct the frames, supports, and shelves themselves. The durability and strength of steel coils ensure that the storage shelves can withstand heavy loads and provide long-lasting storage solutions.

- Q: what does steel have inside of it that makes it rust.I need the answer fast!!!!!!!!!

- Oxygen in the air reacts to Iron particles in steel to form Iron Oxide (commonly known as rust).

- Q: What are the common uses of stainless steel coils?

- Stainless steel coils have various common uses in different industries. Some of the most common applications include manufacturing of kitchen appliances, automotive parts, construction materials, and medical equipment. Additionally, they are used in the production of pipes, tubes, and wire products, as well as in the food and beverage industry for processing and storage equipment.

- Q: How are steel coils used in the production of roofing and siding?

- Steel coils are an essential component in the production of roofing and siding materials. These coils, made from high-quality steel, undergo various processes to transform them into the final products used for roofing and siding purposes. Firstly, the steel coils are uncoiled and flattened to obtain a flat sheet of steel. This sheet is then cleaned to remove any impurities or contaminants. The cleaning process involves treating the surface of the steel with chemicals and rinsing it thoroughly to ensure a clean and smooth surface. Next, the steel sheet is coated with a protective layer to enhance its durability and resistance to corrosion. This coating can be done through various methods such as hot-dip galvanizing, electro-galvanizing, or applying a layer of metallic or organic coating. The specific coating method depends on the desired properties and aesthetic requirements of the roofing or siding material. After the coating process, the steel sheet is formed into the desired shape and profile. For roofing applications, the steel sheet is typically corrugated or formed into interlocking panels. This allows for easy installation and ensures a secure and weatherproof roofing system. Similarly, for siding applications, the steel sheet can be formed into different profiles such as horizontal or vertical panels, shingles, or shakes. Once the steel sheet is formed, it may undergo additional treatments to enhance its performance. This can include applying a protective layer of paint or other finishes to improve its appearance and resistance to fading, chipping, or scratching. The steel coils can also be embossed or stamped with patterns or textures to provide aesthetic appeal. Overall, steel coils play a crucial role in the production of roofing and siding materials. They provide strength, durability, and weather resistance, making them an ideal choice for protecting buildings from the elements. Additionally, steel coils offer versatility in terms of shape, profile, and finish, allowing for a wide range of design options for roofing and siding applications.

- Q: How are steel coils used in the production of HVAC systems?

- Steel coils are used in the production of HVAC systems as a key component in the heat exchange process. They are typically used in the condenser and evaporator coils to transfer heat between the refrigerant and the air. The steel coils provide a durable and efficient surface for heat transfer, ensuring the HVAC system can effectively cool or heat the air.

- Q: What are the safety precautions to be followed while handling steel coils?

- When handling steel coils, it is important to follow certain safety precautions to prevent accidents and injuries. Here are some safety precautions to be followed: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, steel-toed boots, and hard hats. These items will protect you from potential hazards like falling objects, sharp edges, and chemicals. 2. Proper Lifting Techniques: Use proper lifting techniques to prevent strains and back injuries. Lift with your legs, not your back, and avoid twisting or jerking motions while handling the coils. If the coils are too heavy or awkward to lift manually, use mechanical lifting equipment like forklifts or cranes. 3. Secure Storage: Store steel coils in a secure and stable manner to prevent them from falling or rolling over. Use proper racks, shelves, or storage containers designed specifically for steel coils. Ensure that the storage area is clean, organized, and free from obstructions. 4. Handling Tools: Use appropriate handling tools like coil hooks, lifting clamps, or coil tongs to securely grip the steel coils. Avoid using makeshift or improper tools, as they can cause the coils to slip, resulting in accidents. 5. Secure Transportation: When transporting steel coils, ensure they are properly secured on the truck or flatbed. Use appropriate tie-downs, straps, or chains to prevent the coils from shifting or falling during transit. Follow all transportation regulations and guidelines to ensure safe transportation. 6. Awareness of Surroundings: Be aware of your surroundings and the presence of other workers or equipment in the area. Maintain a safe distance from moving machinery, forklifts, or other vehicles to avoid collisions or accidents. 7. Hazard Communication: Ensure that all employees handling steel coils are trained on proper safety procedures and understand the potential hazards involved. Display safety signs or labels to indicate the presence of heavy loads or hazardous materials. 8. Regular Maintenance: Regularly inspect and maintain equipment, such as lifting devices or storage racks, to ensure they are in good working condition. Report any defects or malfunctions to the appropriate personnel for prompt repairs. By following these safety precautions, you can minimize the risk of accidents, injuries, and damage when handling steel coils. It is important to prioritize safety in order to protect yourself and your coworkers in the workplace.

- Q: What are the different types of steel coil surface treatments?

- There are several different types of steel coil surface treatments, including hot-dip galvanizing, electro-galvanizing, painting, and powder coating.

- Q: What are the common problems encountered with steel coils during production?

- Some common problems encountered with steel coils during production include surface defects such as scratches, rust, and scale formation, dimensional deviations, coil breaks or tears, edge defects, and coil slippage. Other issues may include coil handling and storage problems, coil winding or coiling defects, and quality control problems such as inconsistent chemical composition or mechanical properties.

- Q: How do steel coils contribute to energy performance in buildings?

- Steel coils contribute to energy performance in buildings through their use in the construction of energy-efficient heating, ventilation, and air conditioning (HVAC) systems. Steel coils are commonly used in HVAC equipment, such as air handlers and heat exchangers, due to their excellent thermal conductivity and durability. By efficiently transferring heat or cool air, steel coils help regulate the temperature in buildings, reducing energy consumption and improving overall energy performance. Additionally, steel coils are often used in the construction of insulated panels and roofing systems, providing excellent insulation and preventing thermal bridging, thereby further enhancing the energy efficiency of buildings.

Send your message to us

PPGI Color Coated Galvanized/Aluzinc Steel Sheet in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords