PPGI Coils from Tianjin Steel Material Mills

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PPGI Coils from Shandong

Description of PPGI Coils from Shandong

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of PPGI Coils from Shandong

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

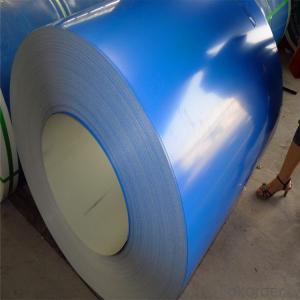

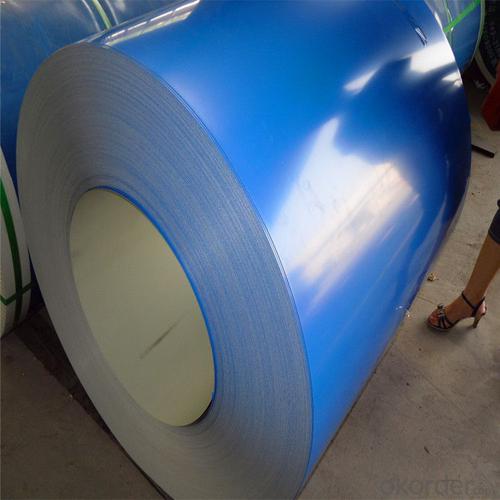

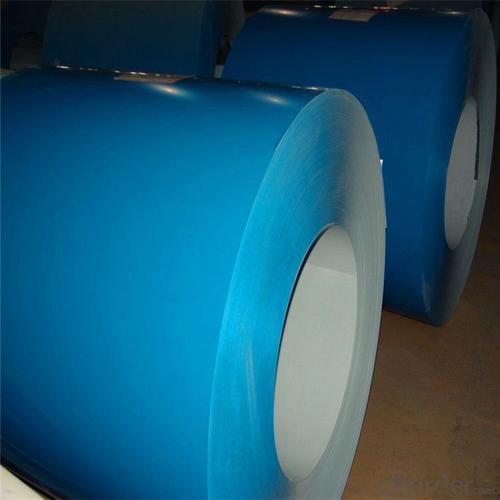

Products Show of PPGI Coils from Shandong

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can special steel be used in the defense sector?

- Indeed, in the defense sector, special steel finds itself as a viable option. Special steel, which encompasses alloys or compositions designed with specific attributes such as high strength, hardness, resistance to corrosion, or heat resistance, proves to be suitable for a range of defense applications. These applications include the construction of armored vehicles, naval vessels, aircraft, and weaponry. Within the defense sector, special steel serves as a valuable resource for manufacturing components and structures necessitating exceptional strength and durability. For instance, it can be utilized to produce armor plates for tanks and armored vehicles, which must endure high impact and ballistic threats. Additionally, special steel can be employed in the construction of naval vessels, providing corrosion resistance and enhancing overall structural integrity. Furthermore, the defense industry heavily relies on special steel for manufacturing aircraft parts and weaponry. Aircraft components, such as landing gear, engine parts, and structural elements, demand materials of high strength to ensure safe and reliable operation. Special steel alloys fulfill this requirement by providing the necessary strength and resistance to extreme conditions, including high temperatures and pressures, making them an ideal choice for these applications. Moreover, special steel plays a vital role in the production of various types of weapons, such as firearms and blades. Its exceptional strength and hardness properties render it suitable for manufacturing gun barrels, bulletproof vests, and knives employed by military personnel. To summarize, special steel holds significant value within the defense sector due to its exceptional properties, including strength, hardness, corrosion resistance, and heat resistance. Its extensive applications in the construction of armored vehicles, naval vessels, aircraft, and weaponry ensure the safety, durability, and effectiveness of military equipment.

- Q: How is special steel used in the production of engine components?

- Special steel is used in the production of engine components due to its exceptional strength, durability, and resistance to heat and corrosion. It is commonly used to manufacture parts such as crankshafts, camshafts, connecting rods, and valves, which are subjected to high stress and temperature conditions. The special steel's properties enable these components to withstand the demanding operating conditions of engines, resulting in enhanced performance, reliability, and longevity.

- Q: How does special steel ensure product traceability?

- Product traceability is guaranteed in special steel through a variety of measures and processes implemented during production and supply chain management. To begin with, detailed records of the production process are maintained by special steel manufacturers. These records encompass information on the raw material source, specific production techniques utilized, and the testing and inspection procedures carried out at each stage. By possessing these records, a comprehensive traceability is achieved as they provide a clear historical account of each product from its inception to its final form. Special steel manufacturers also adopt robust quality control systems that involve assigning unique identification codes or markings to each product. These codes aid in tracking the product throughout its lifecycle, facilitating easy identification and traceability. Furthermore, advanced technology systems such as barcode scanning, radio frequency identification (RFID), or blockchain are often employed by special steel manufacturers to monitor and trace their products. These systems enable real-time monitoring and recording of product movements, thereby ensuring accurate traceability and transparency. Additionally, special steel manufacturers maintain strong relationships with their suppliers and customers, establishing a transparent and traceable supply chain. They collaborate closely with suppliers to validate the origin and quality of raw materials, while also working closely with customers to provide them with detailed information regarding the product's manufacturing process and its journey through the supply chain. In conclusion, special steel manufacturers prioritize product traceability by implementing stringent record-keeping systems, advanced technology solutions, and maintaining transparent relationships with suppliers and customers. These measures not only guarantee the quality and reliability of special steel products, but also provide customers with assurance regarding the origin and authenticity of the product.

- Q: How does special steel maintain its strength at different temperatures?

- Special steel maintains its strength at different temperatures due to its unique composition and heat treatment process. It is alloyed with elements like chromium, nickel, and molybdenum, which form stable compounds at high temperatures, preventing the steel from losing its strength. The heat treatment process involves carefully controlling the cooling rate, which further enhances the steel's microstructure and ensures its strength is retained even at extreme temperatures.

- Q: How does the composition of special steel affect its mechanical properties?

- The composition of special steel significantly affects its mechanical properties. Various alloying elements such as carbon, manganese, chromium, nickel, and others are added in specific quantities to enhance the steel's strength, hardness, toughness, and corrosion resistance. The presence and ratio of these elements determine the steel's microstructure, which in turn determines its mechanical properties. For example, higher carbon content increases hardness and strength, while manganese improves toughness. Similarly, chromium and nickel increase corrosion resistance and provide better heat resistance. Therefore, the composition of special steel plays a crucial role in defining its mechanical properties.

- Q: How does special steel contribute to improving product reliability?

- Special steel contributes to improving product reliability in several ways. Firstly, special steel has enhanced mechanical properties, such as high strength, toughness, and corrosion resistance, making it highly suitable for demanding applications. This ensures that products made with special steel are more durable and less likely to fail under stress or harsh conditions. Secondly, special steel can be tailored to specific requirements, allowing manufacturers to optimize the material for a particular product. This customization ensures that the steel used is the most suitable for the application, improving overall product performance and reliability. Furthermore, special steel undergoes rigorous quality control and testing processes during manufacturing. This ensures that the material meets strict standards and specifications, reducing the risk of defects or inconsistencies that could compromise product reliability. In summary, special steel's superior mechanical properties, customization options, and stringent quality control contribute to improved product reliability by enhancing durability, performance, and consistency.

- Q: Can special steel be used in electrical applications?

- Special steel can indeed find its use in electrical applications. There exist specific properties in special steel alloys, like stainless steel or tool steel, that render them appropriate for usage in electrical applications. These properties encompass excellent electrical conductivity, remarkable resistance against corrosion, and commendable strength. To illustrate, stainless steel frequently finds its application in electrical enclosures, wire mesh, and connectors, owing to its ability to ward off corrosion caused by moisture or chemicals. Conversely, tool steel is commonly employed in the production of electrical tools and equipment, such as pliers or screwdrivers, due to its superior strength and durability. On the whole, special steel alloys can provide the desired electrical properties and performance required for diverse electrical applications.

- Q: What are the different types of nitriding steel?

- There are several types of nitriding steel, including gas nitriding steel, salt bath nitriding steel, plasma nitriding steel, and ion nitriding steel. Each type of nitriding steel has its own unique characteristics and advantages, making them suitable for different applications and industries.

- Q: How does special steel perform in marine environments?

- Special steel is specifically designed to withstand the harsh conditions of marine environments. It offers superior corrosion resistance, high strength, and excellent durability, making it highly suitable for applications in marine settings. This type of steel can effectively resist the corrosive effects of saltwater, moisture, and other environmental factors, ensuring long-term performance and reducing maintenance requirements.

- Q: Can special steel be used in construction?

- Yes, special steel can be used in construction. Special steel, also known as alloy steel, offers superior strength, durability, and resistance to corrosion and wear compared to regular steel. It is commonly used in the construction of high-rise buildings, bridges, and other structures that require exceptional strength and longevity. Additionally, special steel can be customized to meet specific project requirements, making it a versatile choice for construction applications.

Send your message to us

PPGI Coils from Tianjin Steel Material Mills

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords