Secondary PPGI Steel Coils from Shangdong

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

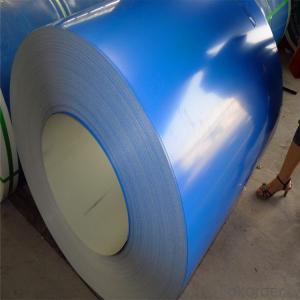

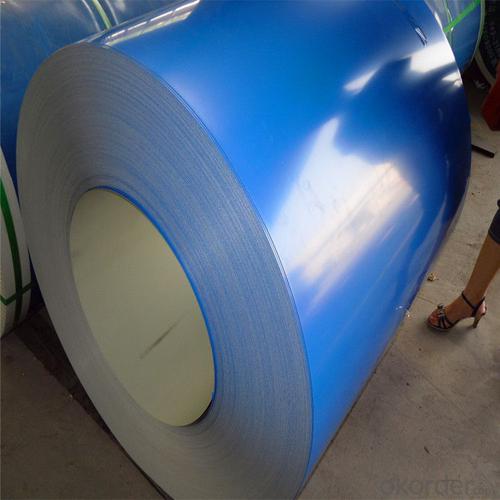

Secondary PPGI Steel Coils

Description of Secondary PPGI Steel Coils

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Secondary PPGI Steel Coils

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

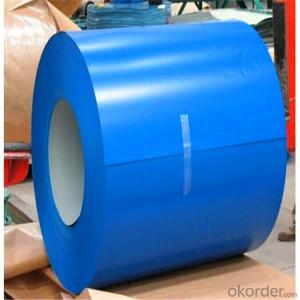

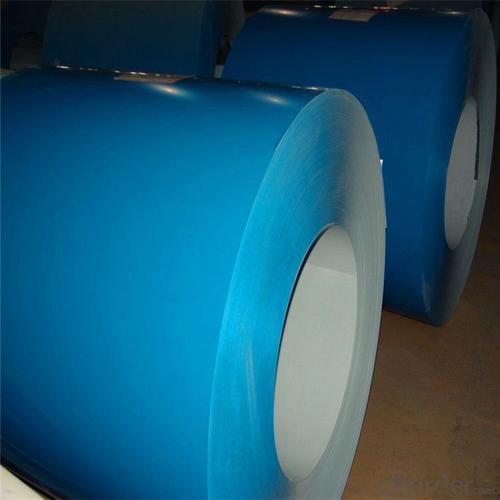

Products Show of Secondary PPGI Steel Coils

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How are tool steels used in the manufacturing of cutting tools?

- Tool steels are used in the manufacturing of cutting tools due to their high hardness, wear resistance, and ability to withstand high temperatures. They are typically used to create the blades or edges of cutting tools such as drills, saws, and knives. Tool steels allow for precise and efficient cutting by maintaining their sharpness for longer durations, providing durability and strength to the cutting tools.

- Q: How does special steel perform in high-stress environments?

- Special steel performs exceptionally well in high-stress environments due to its unique properties. Its enhanced strength, durability, and resistance to corrosion make it highly reliable and capable of withstanding extreme conditions. This allows it to maintain its structural integrity and prevent deformation or failure, making it ideal for use in demanding industries like aerospace, oil and gas, and automotive.

- Q: What is the significance of special steel in the medical field?

- Special steel, which is also referred to as medical grade steel, holds a vital role in the medical field due to its distinct properties and importance. Specifically designed and produced to meet the strict requirements of the healthcare industry, special steel's significance in the medical field can be grasped through the following points: 1. Biocompatibility: Special steel demonstrates biocompatibility, meaning it is non-toxic and does not elicit an adverse reaction when it comes into contact with the human body. This makes it an ideal material for medical devices like surgical instruments, implants, and orthopedic tools. 2. Resistance to corrosion: Special steel exhibits high resistance to corrosion and rust, ensuring the endurance and durability of medical instruments. Instruments used in surgical procedures require repeated sterilization, and the corrosive nature of sterilization agents can degrade ordinary steel. Special steel, with its superior resistance to corrosion, can withstand these harsh conditions, decreasing the risk of contamination and preserving the integrity of medical equipment. 3. Mechanical properties: Special steel possesses exceptional mechanical properties, such as high strength, toughness, and ductility. These characteristics are crucial for medical devices as they need to endure the stresses and strains of surgical procedures, maintain their shape, and deliver reliable performance. 4. Compatibility with sterilization: Special steel can withstand various sterilization methods, including steam sterilization, ethylene oxide sterilization, and gamma radiation. This guarantees that medical instruments made from special steel can be effectively sterilized, preventing the transmission of infections and minimizing the risk of contamination during surgeries. 5. Precision manufacturing: Special steel can be shaped into intricate forms and sizes, enabling the production of precise medical instruments. Its superior machinability allows for the creation of fine and sharp edges, which are vital for surgical tools used in delicate procedures. 6. Antibacterial properties: Certain special steels, such as stainless steel, possess inherent antibacterial properties. This characteristic is particularly crucial in the medical field, where preventing infections is of utmost importance. Instruments made from antibacterial special steel can hinder the growth of bacteria, minimizing the risk of post-operative complications. In conclusion, the significance of special steel in the medical field lies in its biocompatibility, resistance to corrosion, mechanical properties, compatibility with sterilization, precision manufacturing, and potential antibacterial properties. These qualities render special steel an indispensable material for the manufacturing of medical devices, ensuring their dependability, durability, and safety for both healthcare professionals and patients.

- Q: What are the different nuclear grades of special steel?

- The different nuclear grades of special steel refer to specific types of steel that are used in the nuclear industry to meet stringent requirements for safety, reliability, and performance. These grades are designed to withstand the harsh conditions of nuclear power plants and other nuclear facilities. There are several nuclear grades of special steel, each with its own unique characteristics and applications. Some of the commonly used grades include: 1. 304/304L stainless steel: This grade is widely used in nuclear applications due to its excellent corrosion resistance and high strength at elevated temperatures. It is often used in the construction of reactor vessels, heat exchangers, and piping systems. 2. 316/316L stainless steel: Similar to 304/304L, this grade offers superior corrosion resistance and high creep strength. It is commonly used in the construction of components exposed to corrosive environments, such as coolant systems, steam generators, and fuel handling equipment. 3. 321 stainless steel: This grade contains titanium, which stabilizes the steel against sensitization during welding. It is often used in nuclear applications where welding is required, such as piping systems and pressure vessels. 4. Duplex stainless steels: These grades, such as 2205 and 2507, offer a combination of high strength and excellent corrosion resistance. They are commonly used in nuclear applications involving highly corrosive environments, such as seawater-cooled systems and containment structures. 5. Low alloy steels: These steels, such as A533B and A508, are used in the construction of reactor pressure vessels due to their high strength and toughness. These grades are specifically designed to withstand the extreme conditions within a nuclear reactor. It is important to note that the selection of the appropriate nuclear grade of special steel depends on the specific application, considering factors such as temperature, pressure, corrosion resistance, and mechanical properties. These grades undergo rigorous testing and quality control measures to ensure their suitability for use in the nuclear industry.

- Q: How does special steel contribute to the ductility of products?

- Special steel's ability to enhance the ductility of products is attributed to its distinct composition and manufacturing techniques. Ductility refers to a material's capacity to deform under stress without fracturing or breaking. In the case of special steel, its composition incorporates specific alloying elements that bolster its ductility. One way in which special steel augments ductility is by reducing the presence of impurities. Stringent quality control measures are employed during the production of special steel to ensure that impurities like sulfur and phosphorus are kept at minimal levels. These impurities have the potential to render steel brittle, thereby diminishing its ductility. By minimizing their presence, special steel retains its ability to deform without failure. Moreover, special steel often contains particular alloying elements such as nickel, chromium, and molybdenum. These alloying elements play a critical role in enhancing ductility. For instance, nickel enhances the toughness and ductility of steel by increasing its capacity to absorb energy before fracturing. On the other hand, chromium enhances the steel's resistance to corrosion and oxidation, thereby safeguarding its ductility. The manufacturing processes employed in producing special steel also contribute to its ductility. Precise temperature control during the heat treatment of special steel can optimize its microstructure, resulting in improved ductility. Additionally, special steel can undergo various forming processes, such as hot or cold rolling, which further refine its microstructure and augment its ductility. In conclusion, special steel's unique composition, minimal impurity levels, inclusion of specific alloying elements, and meticulous manufacturing processes significantly contribute to its ductility. Consequently, it is an excellent choice for applications that require deformation without failure, such as automotive components, machinery parts, and structural applications.

- Q: How does special steel comply with international standards?

- Special steel, specifically designed and manufactured to possess exceptional properties and performance, undergoes a rigorous process to ensure its quality and conformity to established norms. To begin with, adherence to international standards in the production of special steel is achieved through the meticulous selection of raw materials. The composition and quality of these materials are carefully controlled and tested to meet the specifications outlined by international standards organizations. This guarantees that the resulting special steel is of the desired quality and possesses the necessary mechanical properties. In addition, standardized production processes are followed by special steel manufacturers. These processes are designed in accordance with international guidelines and standards to ensure consistency and traceability. Through the use of advanced technologies and quality control measures, manufacturers can monitor and control every stage of production, from melting and casting to rolling and heat treatment. This guarantees that the final product meets the required standards in terms of chemical composition, mechanical properties, and dimensional tolerances. Moreover, stringent testing and inspection procedures are conducted to validate the compliance of special steel with international standards. Certified laboratories and independent third-party agencies perform various destructive and non-destructive testing methods, such as ultrasonic testing, hardness testing, and microstructure analysis. These tests ensure unbiased and accurate results. Furthermore, special steel manufacturers often have their production processes and quality management systems audited and certified by recognized bodies, like ISO, to demonstrate their commitment to compliance with international standards. It is also important to note that special steel manufacturers actively participate in international standardization committees, such as ASTM International and ISO. By engaging in these committees, they contribute to the development and revision of international standards, ensuring that their products remain up to date and aligned with the latest industry requirements. In conclusion, special steel complies with international standards through careful raw material selection, adherence to standardized production processes, rigorous testing and inspection, and active participation in international standardization committees. By following these measures, special steel manufacturers demonstrate their dedication to producing high-quality products that meet the strict requirements of international standards.

- Q: How does special steel contribute to the dimensional stability of products?

- Special steel is known for its high strength, durability, and resistance to deformation, making it an ideal material for enhancing the dimensional stability of products. By utilizing special steel in the manufacturing process, products are less likely to experience changes in shape or size due to external factors such as temperature fluctuations or mechanical stress. This improved dimensional stability ensures that the products maintain their intended form and functionality over time, leading to increased reliability and customer satisfaction.

- Q: How does special steel perform in aerospace applications?

- Due to its exceptional performance and unique properties, special steel finds extensive use in aerospace applications. A primary reason for its usage lies in its high strength-to-weight ratio, a crucial factor in the aerospace industry where weight reduction is of utmost importance. Special steel alloys exhibit superior strength, enabling them to withstand the extreme conditions experienced during flight, including high temperatures, vibrations, and pressure changes. Moreover, special steel possesses excellent corrosion resistance, making it an ideal choice for aerospace applications where exposure to moisture and various chemicals is common. Its corrosion resistance ensures the durability and longevity of critical components, resulting in reduced maintenance and replacement costs. Furthermore, special steel offers excellent fatigue resistance, allowing it to endure repeated loading and unloading cycles without deformation or failure. This property is vital in aerospace applications where components must withstand cyclic stresses and maintain their integrity for extended periods. Additionally, special steel alloys can be readily fabricated and machined, facilitating the production of intricate and precise aerospace components. The ease of fabrication ensures efficient manufacturing processes and the ability to create complex designs, which are essential for optimizing performance and aerodynamics. In conclusion, special steel's exceptional strength, corrosion resistance, fatigue resistance, and ease of fabrication make it an invaluable material in aerospace applications. Its utilization in critical components, such as turbine blades, landing gears, and structural elements, guarantees the safety, reliability, and efficiency of aerospace systems.

- Q: How does special steel contribute to the chemical processing aftermarket industry?

- Special steel plays a crucial role in the chemical processing aftermarket industry by offering a wide range of benefits that enhance the overall efficiency and performance of chemical processing equipment. Firstly, special steel is renowned for its exceptional strength and durability, making it ideal for applications that involve high pressure, extreme temperatures, and corrosive environments. This durability ensures that the equipment can withstand the challenging conditions and operate reliably for extended periods, reducing the frequency of maintenance and replacement. Furthermore, special steel possesses excellent resistance to corrosion, oxidation, and chemical reactions, which are common challenges in the chemical processing industry. This resistance enables the equipment to handle a wide variety of chemicals without deteriorating or contaminating the process, thus ensuring the quality and safety of the end products. Additionally, special steel can withstand the formation of scale, deposits, and other contaminants that can hinder the efficiency of the equipment, thereby reducing the need for frequent cleaning and maintenance. Moreover, special steel offers superior mechanical properties such as toughness, hardness, and impact resistance, which are essential for handling and processing heavy loads and abrasive materials. This ensures that the equipment can withstand the demanding operational conditions and maintain its performance over time, resulting in enhanced productivity and reduced downtime. Another significant contribution of special steel to the chemical processing aftermarket industry is its versatility. It can be customized and tailored to meet specific requirements, allowing for the manufacturing of complex parts and components that are essential for various chemical processes. Special steel can be fabricated into different shapes and sizes, enabling the creation of intricate designs and structures that optimize the efficiency and effectiveness of the equipment. In conclusion, special steel is a vital component in the chemical processing aftermarket industry due to its exceptional strength, durability, resistance to corrosion and chemical reactions, as well as its versatility. By providing reliable and high-performance equipment, special steel contributes significantly to the overall efficiency, safety, and productivity of chemical processing operations.

- Q: What are the properties of titanium alloys?

- Titanium alloys have several notable properties, including high strength-to-weight ratio, excellent corrosion resistance, and good biocompatibility. These alloys also exhibit high temperature stability, low thermal expansion, and great fatigue strength, making them suitable for a wide range of applications in industries such as aerospace, automotive, and medical.

Send your message to us

Secondary PPGI Steel Coils from Shangdong

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords