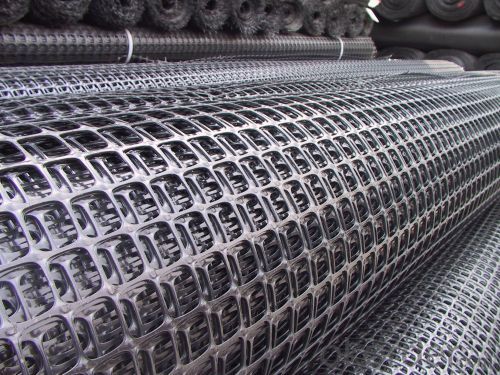

Nysdot Approved PP Plastic Biaxial Geogrid by Manufactory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

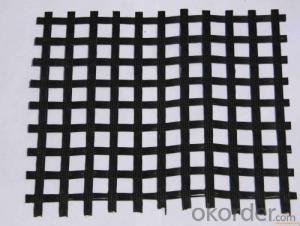

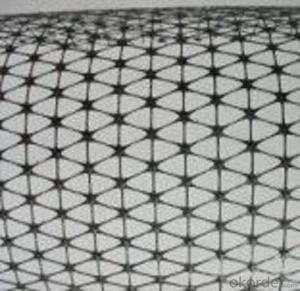

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

(1)High intension,high tenacity,high occlusive force with soil or gravel,erosion-resistant,

water drainage,light weigth.

(2)Reinforce soft soil roadbed,rib side slope of embankment,enhance isolation,

inhibit ground deformation,prevent crack by reflection,increase strength of roadbed.

The main function as follows:

1.Reinforce the base, efficiently allot and diffuse the pressure, prolong the using time;

2.Increase the load-bearing capabilities;

3.Avoid the base becoming deformed and creaking (for the material washed away);

4.Improve the endure, reduce the pressure of the blocking wall, save the cost, prolong the using time, and reduce the servicing;

5.Reduce the crook and track, delay 3-9 times of the appearance of the crack, reduce 36% of the thickness of the structure by adding the geogrid into the base and cover of the road,

6.Be applicable of all kinds of soil;

7.Be easy to construct and reduce the cost.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: Can geogrids be used for retaining walls?

- Yes, geogrids can be used for retaining walls. Geogrids are commonly used in the construction of retaining walls to provide additional stability and reinforcement to the soil. They help distribute the load and prevent the soil from shifting, improving the overall strength of the wall.

- Q: I would like to ask the Lebanon warp knitting machine, the model is: Cop - HS_2ST geogrid do know how to process

- This model is the industrial warp knitting machine, axial weft, used in roads, rivers, buildings, agriculture, etc..

- Q: Can geogrids be used in reinforcement of soft ground?

- Yes, geogrids can be used in the reinforcement of soft ground. Geogrids are commonly used to improve the stability and load-bearing capacity of weak or soft soil by distributing the applied loads and reducing settlement. They are effective in reinforcing soft ground and can provide increased strength and stability to the soil, making them a suitable solution for various civil engineering and construction projects.

- Q: What are the typical dimensions and sizes of geogrids?

- Geogrids typically come in varying dimensions and sizes, depending on the specific application and engineering requirements. However, common dimensions for geogrids range from 1 to 6 meters in width and 50 to 100 meters in length. The size of the apertures or openings in the geogrid can also vary, typically ranging from 20 to 50 millimeters. It is important to consider the specific project needs and consult with an engineer to determine the most suitable dimensions and sizes for geogrids.

- Q: Are geogrids resistant to aging?

- Yes, geogrids are generally resistant to aging. They are designed to withstand long-term exposure to environmental factors such as UV radiation, temperature fluctuations, and chemical exposure, which helps to maintain their strength and durability over time.

- Q: What are the advantages of using geogrids in ground improvement for settlement control?

- Geogrids offer several advantages in ground improvement for settlement control. Firstly, they provide increased soil stability by distributing loads more evenly, thereby reducing settlement and preventing soil erosion. Secondly, geogrids enhance soil reinforcement, increasing the bearing capacity of the ground and allowing for the construction of heavier structures. Additionally, these materials are easy to install and cost-effective, saving time and money during the ground improvement process. Overall, geogrids offer a reliable and efficient solution for settlement control and improved ground stability.

- Q: How do geogrids improve soil reinforcement?

- Geogrids improve soil reinforcement by providing additional tensile strength to the soil, preventing lateral movement and improving its overall stability. They act as a reinforcement material that distributes the load over a wider area, reducing the stress on the soil and preventing its failure. Additionally, geogrids increase the frictional resistance between soil particles, enhancing the soil's shear strength and preventing soil erosion.

- Q: What is the typical geogrid roll weight for specific applications?

- The typical geogrid roll weight for specific applications can vary depending on the specific type and purpose of the geogrid. However, geogrid rolls commonly range in weight from 200 to 1,000 pounds, with some heavier-duty options weighing even more for specialized applications.

- Q: What is the effect of confinement on geogrid performance?

- The effect of confinement on geogrid performance is generally positive. Confinement provides additional support and improves the load-bearing capacity of geogrids. It helps to distribute the load more evenly, reduces lateral movement, and enhances the overall stability of the geogrid system. Confinement can increase the tensile strength and stiffness of the geogrid, allowing it to withstand higher loads and provide better reinforcement.

- Q: What is the effect of temperature on geogrid properties?

- The effect of temperature on geogrid properties can vary depending on the specific type of geogrid. In general, temperature can affect the mechanical properties of geogrids, such as tensile strength, stiffness, and creep behavior. Higher temperatures can soften the geogrid material, reducing its strength and stiffness. Conversely, lower temperatures can make the material more brittle. Therefore, it is important to consider the temperature conditions in which geogrids will be used to ensure their optimal performance and longevity.

Send your message to us

Nysdot Approved PP Plastic Biaxial Geogrid by Manufactory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords