Light Weight PP Plastic Polypropylene Geogrid Biaxial Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Plastic polypropylene geogrid biaxial

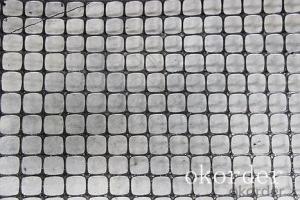

The properties of Biaxial Geogrids, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

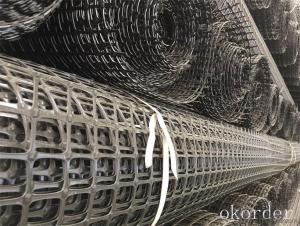

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the effect of geogrid aperture size on performance?

- The effect of geogrid aperture size on performance is that a smaller aperture size generally leads to better performance. This is because a smaller aperture size allows for better soil confinement and interlocking, resulting in improved stability, load distribution, and overall performance of the geogrid. A larger aperture size, on the other hand, may lead to reduced confinement and interlocking, potentially compromising the geogrid's performance.

- Q: How do geogrids improve the load transfer in road pavements?

- Geogrids improve the load transfer in road pavements by providing reinforcement and stabilization to the layers of the pavement. They are typically made of high-strength materials and are placed within the pavement layers to distribute the load more evenly, reduce deformation, and enhance the overall structural integrity of the road. This helps in preventing cracks, rutting, and other pavement distresses, ultimately extending the lifespan and improving the performance of the road.

- Q: Can geogrids be used in temporary retaining structures?

- Yes, geogrids can be used in temporary retaining structures. Geogrids are commonly used in retaining walls and slopes to provide reinforcement and stability. They help distribute the load, prevent soil erosion, and enhance the overall strength of the structure. Therefore, they can be an effective solution for temporary retaining structures as well.

- Q: What are the specifications for geogrid installation?

- The specifications for geogrid installation typically include factors such as the type and strength of the geogrid material, the required overlap or seam allowance, the recommended depth of installation, the recommended slope angle for placement, and any specific site preparation or soil compaction requirements. Other factors to consider may include the desired load-bearing capacity, the expected lifespan of the geogrid, and any additional reinforcement or anchoring methods necessary. It is important to consult the manufacturer's guidelines and any relevant engineering or construction standards for specific specifications and recommendations.

- Q: Are geogrids suitable for use in green roof systems?

- Yes, geogrids are suitable for use in green roof systems. They provide structural support and reinforcement for the soil and vegetation layers, helping to prevent soil erosion and improve the overall stability and longevity of the green roof system. Geogrids also aid in distributing the load and reducing stress on the roof structure.

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- There are several factors that can affect the installation and survivability of geogrids in harsh environments. Firstly, the type and quality of the geogrid material plays a crucial role. Geogrids made from high-strength polymers or synthetic fibers are more likely to withstand extreme conditions. Secondly, the design and installation techniques used are important factors. Proper anchoring, tensioning, and overlap of geogrids can enhance their durability in harsh environments. Additionally, the soil type and its characteristics, such as cohesion and friction angle, can impact the performance of geogrids. The presence of aggressive chemicals, temperature fluctuations, and exposure to UV radiation are other factors that can affect their survivability. Overall, a thorough understanding of these factors and adherence to best practices during installation are essential for ensuring the successful functioning of geogrids in harsh environments.

- Q: Is the test items within the inspection listAcceptance specification

- Lower bearing layer smoothness

- Q: What are the specifications and models of Geotextiles and geogrids on the highway

- Steel plastic composite grille GS30-30 GS60-60 GS80-80 GS150-150 width 4-6m meters GS80-60 GS50-50;Glass fiber grille BJG35-35 BJG60-60 BJG80-80 BJG100-100 width 1-6 meters (BJG50-50);

- Q: How do geogrids improve the performance of paved and unpaved roads?

- Geogrids improve the performance of paved and unpaved roads by providing reinforcement and stabilization to the soil and pavement layers. They distribute loads more evenly, reducing the formation of cracks and potholes. Geogrids also enhance the tensile strength of the road, allowing it to withstand heavier traffic and minimize deformation. Overall, geogrids increase the durability, lifespan, and structural integrity of both paved and unpaved roads.

- Q: What are the design considerations for geogrids in reinforced soil slopes?

- Some design considerations for geogrids in reinforced soil slopes include the type and strength of the geogrid material, proper installation techniques, adequate spacing and orientation of the geogrid layers, and the required length and width of the geogrid reinforcement. Additionally, factors such as the soil properties, slope geometry, and anticipated loads must be considered to ensure the geogrids can effectively stabilize the slope and prevent soil erosion or failure.

Send your message to us

Light Weight PP Plastic Polypropylene Geogrid Biaxial Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords