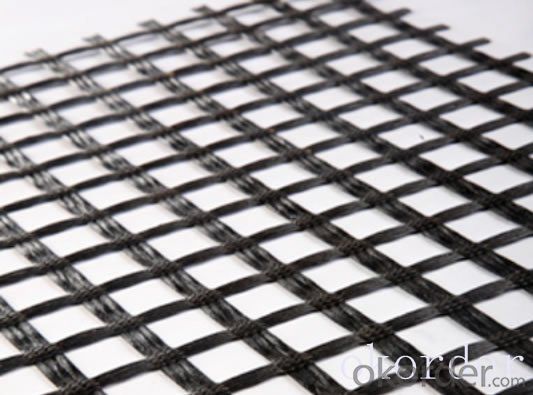

Reinforcement Geogrids - PP Plastic Polypropylene Biaxial Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

PP Plastic polypropylene geogrid biaxial

The properties of Biaxial Geogrids, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the advantages of using geogrids in mechanically stabilized aggregate bases?

- There are several advantages of using geogrids in mechanically stabilized aggregate bases. Firstly, they improve the overall stability and strength of the base by distributing and transferring loads more efficiently. This helps to prevent deformations and rutting, leading to a longer-lasting and more durable pavement structure. Secondly, geogrids can reduce the thickness of the aggregate base required, resulting in cost savings and a more sustainable construction approach. Additionally, they enhance the performance of the base by minimizing the potential for differential settlement and improving overall load-bearing capacity. Finally, geogrids offer better long-term performance by resisting the effects of aging, such as cracking and degradation, which can significantly extend the lifespan of the pavement system.

- Q: How do geogrids help in reducing construction labor requirements?

- Geogrids help in reducing construction labor requirements by providing stability and reinforcement to the soil, thus eliminating the need for extensive excavation and compaction. They distribute loads more evenly, reducing the amount of material needed and the labor involved in handling and compacting it. This ultimately leads to faster and more efficient construction processes with fewer workers required.

- Q: How do geogrids improve the performance of asphalt pavements?

- Geogrids improve the performance of asphalt pavements by providing reinforcement and stability. They effectively distribute the load across the pavement structure, reducing cracking and rutting. Additionally, geogrids enhance the overall strength and durability of the pavement, thus extending its lifespan and reducing maintenance costs.

- Q: Are there any limitations or disadvantages of using geogrids?

- Yes, there are some limitations and disadvantages of using geogrids. Firstly, geogrids are not suitable for all types of soil conditions and may not be effective in areas with highly cohesive or expansive soils. Secondly, geogrids have limited tensile strength and may not be able to withstand heavy loads or extreme environmental conditions. Additionally, geogrids require proper installation techniques for optimal performance, which may increase the overall project cost. Lastly, regular maintenance and inspection are necessary to ensure the long-term effectiveness of geogrids, adding to the maintenance expenses.

- Q: Can geogrids be used in reinforcement of mechanically stabilized slopes?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized slopes. Geogrids are often used to improve the stability and strength of slopes by providing additional reinforcement to the soil. They help to distribute the loads and reduce lateral movement, thus preventing slope failure. Additionally, geogrids can enhance the overall performance and longevity of mechanically stabilized slopes by improving their resistance to erosion and environmental factors.

- Q: Are geogrids effective in reducing pavement rutting?

- Yes, geogrids are effective in reducing pavement rutting. Geogrids provide reinforcement to the pavement structure, distributing loads and reducing the stress on the pavement surface. This helps to prevent the formation and progression of rutting, resulting in improved pavement performance and longevity.

- Q: What are the environmental impacts of using geogrids?

- The environmental impacts of using geogrids can vary depending on factors such as the type of material used, manufacturing processes, and disposal methods. However, some potential impacts include the extraction of raw materials, energy consumption during manufacturing, and the generation of waste and emissions. It is important to consider these factors and ensure proper management and disposal practices to minimize the environmental impacts of using geogrids.

- Q: What are the factors that affect the installation time of geogrids?

- There are several factors that can affect the installation time of geogrids. Some of the key factors include the size and complexity of the project, the type and condition of the soil, the equipment and manpower available, and any unforeseen challenges or obstacles encountered during the installation process. Additionally, factors such as weather conditions and site accessibility can also impact the installation time.

- Q: What is the recommended installation method for geogrids?

- The recommended installation method for geogrids is to first prepare the subgrade by removing any vegetation or loose soil, and then compact the subgrade to achieve a stable base. The geogrid should be unrolled and placed on top of the prepared subgrade, ensuring it is stretched and anchored securely at the edges. Overlapping the geogrid panels by the manufacturer's recommended amount and using connector devices may be necessary. Finally, the geogrid should be covered with an appropriate fill material and compacted in layers to ensure proper integration and load distribution.

- Q: Glass fiber mesh cloth is mainly used in what place

- Main applications are widely used in

Send your message to us

Reinforcement Geogrids - PP Plastic Polypropylene Biaxial Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords