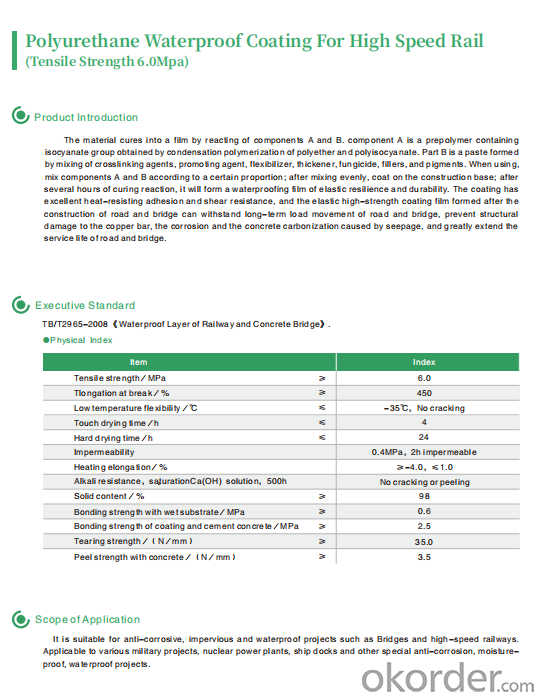

Polyurethane Waterproof Coating For High Speed Rail(Tensile Strength 6.0Mpa)

- Supplier:

BNBM Waterproof Co., Ltd

BNBM Waterproof Co., Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Eastern rainbow waterproof how to do

- General family bathroom is brush JBL waterproof coating, buy back to the first dilution, and then clean up the ground with brushing uniform brushing, the bathroom should brush the ground and the wall 1.6 meters high,

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 3, according to the hydrogeological conditions and outdoor environment type to take the appropriate level of waterproof concrete.

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- Acrylic material thickness is generally below 2MM, Plus the total thickness of glass fiber reinforced plastic materials are generally below 4MM,

- Q: Find the construction steps for waterproof coatings

- 2, waterproof layer construction sequence and methods (1) base surface treatment and acceptance of qualified, and now Yin, Yang angle and construction joints and other special parts brushing waterproof coating layer, strengthen the layer 1 mm, strengthen the layer after brushing, immediately paste fiberglass cloth or 30 ~ 40g / ㎡ polyester cloth reinforcement layer, is strictly prohibited to strengthen the surface layer and then paste the reinforcement layer material. (2) to strengthen the layer of hard work, began to brush a large waterproof layer, waterproof layer using multi-channel (3 to 5) brushing, brushing the upper and lower coating should be perpendicular to each other. When the surface of the coating is completely cured (not sticky hands) before the next curtain coating construction. (3) polyurethane coating waterproofing layer after the completion of the experience of acceptance, the timely application of the waterproof layer of the protective layer, the plane protective layer with 7 cm thick fine stone ㎝, in the pouring of fine stone before the need to cover the waterproof layer A layer of 350 # paper tire linoleum insulation layer. Facade waterproof layer (such as anti-beam facade) with a thick 6 mm polyethylene foam protection (expansion ratio of not more than 25 times).

- Q: Can Henkel have water against him?

- Add a small amount of water is possible because the premise of waterproofing should also be wet before the grassroots

- Q: What is the car material so that the car can be waterproof, in the rain will not leak in?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q: Developers have done waterproof, decoration house also have to do it

- Carbine water to remind you: the general finished house really done by the construction unit waterproofing, but we must know: First of all, developers for the rough housing waterproofing is more casual, may use the poor waterproof performance of the material, in the construction

- Q: Villa roof leakage what general reasons, what materials to remedy

- Third, for some of the city building cover the construction of red tiles leakage, as long as the removal of tiles on the grass, moss or dust after the replacement of tiles, leak-proof effect is the same. For flat roofs, the roof of the obvious cracks, with the tool will be cracked into a "V" or "U" shape, filling the caulking ointment, filled with cracks and above the use of waterproof wrap around the package.

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Third, according to personal experience, SBS membrane waterproof, as long as the quality of waterproof membrane clearance, and in accordance with the requirements of the strict implementation of the implementation, it can be said that the most assured and a roof waterproofing method. Remember: First, the material to cross the border (must be the real polyester carcass), and second, pay attention to the operation carefully in the construction. Just remember these two points, it will not appear too much problem.

- Q: Roof sunscreen waterproof layer leakage, brush milk white plastic can solve it?

- Fourth, for some of the construction of the roof of the cover of Hong Kong leakage, as long as the removal of tiles on the grass, moss or dust after the replacement of tiles, leak-proof effect is the same. For flat roofs, the roof of the obvious cracks, with the tool will be cracked into a "V" or "U" shape, filling the caulking ointment, filled with cracks and above the use of waterproof wrap around the package. To strengthen the leak-proof effect, you can also shop a layer of waterproofing membrane. ? ???Roof leakage how to deal with five, most of the use of clean up the roof, crack filling, crack sealing, mortar to find equal maintenance methods. Waterproof methods are: membrane waterproof, rigid waterproof, flexible waterproof, waterproof coating and other methods. You can also use the plugging the king is better, for the seepage, slightly dug the slot can be directly plugging the dry powder into the tank, compaction, wiping, sprinkler can be maintained. If the investigation is your home to leak water, the main problem should focus on the surface of the leakage interface and the upper part of the section, it is recommended to find professional leak-proof, it is estimated that it is to spend tens of dollars, if you want to repair it To buy a waterproof paint, (the specific name of a lot to go to that kind of store that they know) and then painted in the floor drain and toilet under the mouth of the water pipe and the upper section can be.

Send your message to us

Polyurethane Waterproof Coating For High Speed Rail(Tensile Strength 6.0Mpa)

- Supplier:

BNBM Waterproof Co., Ltd

BNBM Waterproof Co., Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches