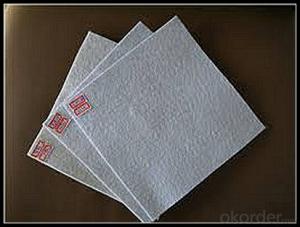

Geotextile Lowes Polypropylene Nonwoven Geotextile Fabrics High Strength Materials for Filtration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextile Functions

Separation

CNBM Geotextile acts as a separator between two layers of soil that have different particle size distributions. CNBM Geotextiles are used to prevent road base materials from penetrating into soft underlying sub grade soils, thus maintaining design thickness and roadway integrity. Separators also help to prevent fine-grained sub grade soils from being pumped into permeable granular road bases.

Filtration

CNBM Geotextile acts similar to a sand filter by allowing water to move through the soil while retaining all upstream soil particles. CNBM Geotextiles are used to prevent soils from migrating into drainage aggregate or pipes while maintaining flow through the system. CNBM Geotextiles are also used below rip rap and other armour materials in coastal and river bank protection systems to prevent soil erosion.

filtration

Reinforcement

CNBM Geotextile acts as a reinforcement element within a soil mass or in combination with the soil to produce a composite that has improved strength and deformation properties over the unreinforced soil. CNBM Geotextiles are used to add tensile strength to a soil mass in order to create vertical or near vertical reinforced soil walls and steep slopes.

Reinforcement

Drainage

CNBM Geotextile acts as a drain to carry fluid flows through less permeable soils or construction structures. CNBM Geotextiles are used to dissipate pore water pressures at the base of roadway embankments. The use of Geotextiles in drainage systems ensures an ongoing drainage of fluids with minimum pressure loss by flowing in-plane of the fabric away from the construction.

Drainage

Protection

Due to excellent static puncture resistance, CNBM Geotextiles protect waterproof membranes and other sealing materials from puncture when fill material and loads are applied. When placed between sealing materials and other layers, CNBM Geotextiles and resists and distributes local pressure from the layer above, ensuring that the protected material is not stressed to failure.

Geo Textiles

CNBM segment comprises of technical textile products used in Geotechnical applications pertaining to soil, rock, earth etc.

This class of product is loosely called Geotextiles.

However Geotextiles particularly refers to permeable fabric or synthetic material, woven or non-woven, which can be used with geotechnical engineering material.

The principal functions performed by Geotextiles are

Confinement /separation,

Reinforcement

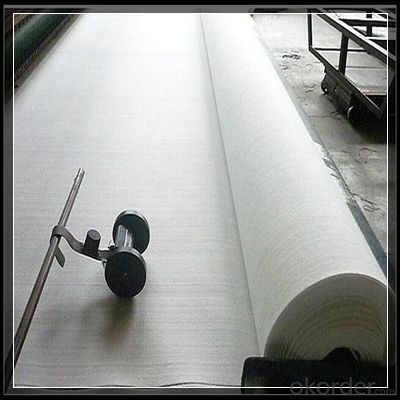

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the main functions of geotextiles?

- The main functions of geotextiles include filtration, separation, reinforcement, and drainage in various civil engineering and construction applications.

- Q: How do geotextiles help with vegetation establishment in landscaping projects?

- Geotextiles help with vegetation establishment in landscaping projects by providing a stable and fertile environment for plants to grow. They prevent soil erosion, control weed growth, retain moisture, and promote healthy root development. Additionally, geotextiles protect plants from foot traffic damage and allow for proper drainage, resulting in successful and sustainable vegetation establishment.

- Q: What are the geotextiles for concrete health

- Do not use non-woven fabrics

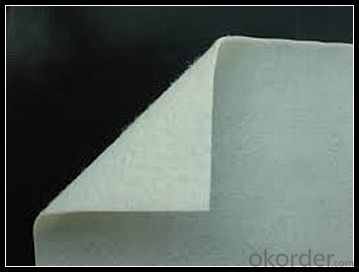

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: What is the meaning of the process equipment and equipment for producing geotextiles?

- What is the meaning of the process equipment and equipment for producing geotextiles?

- Q: 200g geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: Does the color cloth be geotextile?

- Straw, sacks, stone, gravel, wood, steel, color cloth, lighting equipment, transport, alarm equipment, digging tools, lead wire, cement, soil, sand, geotextile and so on.

- Q: There are engineering budgets

- Where are you from where you want to sell

- Q: Can geotextiles be used in canal lining applications?

- Yes, geotextiles can be used in canal lining applications. Geotextiles are commonly used to separate, filter, reinforce, or drain soil in various civil engineering projects, including canal lining. They can help improve the stability, strength, and durability of the canal lining material while providing effective erosion control and preventing water seepage.

- Q: Can geotextiles be used in wastewater treatment systems?

- Yes, geotextiles can be used in wastewater treatment systems. They are often used as filter media or to provide separation and reinforcement in various components of the system, such as in drainage systems, sedimentation tanks, and sludge dewatering processes. Geotextiles help to improve water quality and enhance the efficiency of wastewater treatment processes.

Send your message to us

Geotextile Lowes Polypropylene Nonwoven Geotextile Fabrics High Strength Materials for Filtration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords