Northwest Linings & Geotextile Polypropylene Nonwoven Geotextile Fabric Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

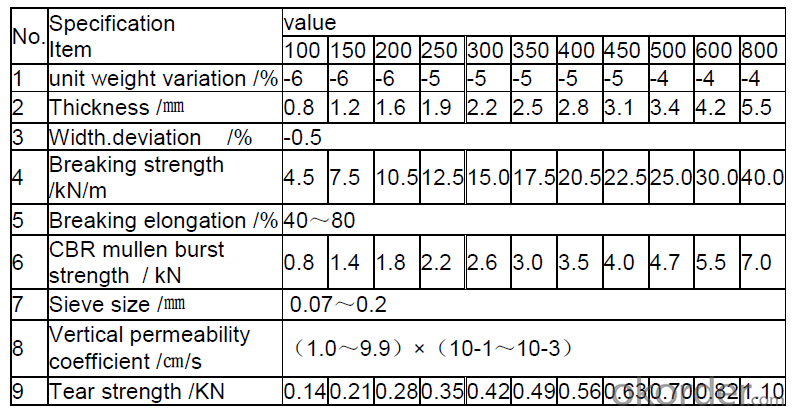

Specification

We offer a wide range of Non Woven Geotextile and Felt Fabrics. Non Woven Geotextile fabrics have their project, structure, or system based on various geo technical materials such as soils, rock, earth etc. Non Woven Geotextile fabrics are either used to restrict or allow passage of Water, as desired. Non Woven Geotextile fabrics are also known as civil engineering fabrics, erosion control cloth, filter fabrics and support membranes.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

specifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in mining tailings management?

- Yes, geotextiles can be used in mining tailings management. Geotextiles are commonly used in mining operations to provide stability and containment for tailings, which are the waste materials left over after the desired minerals have been extracted. They can be used to line tailings storage facilities, prevent erosion, control water flow, and promote soil filtration, thus enhancing the overall management and mitigation of mining tailings.

- Q: Seepage geotextile and impervious geomembrane

- Seepage geotextile is a short wire geotextile, the main thing is to filter water leakage. Impermeable geomembrane is used to waterproof, so the difference between the two is great.

- Q: Do you have a drainage board and geotextile on the roof

- Good, but you use very little, the purchase is difficult, the price will not be cheap Huazhi geotextile material manufacturers

- Q: Can geotextiles be used in agricultural waste management systems?

- Yes, geotextiles can be used in agricultural waste management systems. Geotextiles are commonly used to control erosion, improve drainage, and provide filtration in various applications. In agricultural waste management, they can be utilized to line storage ponds, control the flow of water, and separate different layers of waste materials. Additionally, geotextiles can help in preventing nutrient leaching and protecting the surrounding environment from contamination.

- Q: How many grams of geotextiles on the top of the garage

- We would like to consult a professional company.

- Q: Concrete platform this time to water conservation?

- You say this is the road maintenance geotextile, is a one-time use, and its main role is to prevent the concrete quick-drying and the formation of cracks, the correct approach is that the concrete surface completely hardened before, to keep the geotextile moist, dry.

- Q: How are geotextiles recycled?

- Geotextiles can be recycled through a process called mechanical recycling. This involves collecting used geotextiles, cleaning them, and breaking them down into smaller fibers or pellets. These recycled materials can then be used to manufacture new geotextiles or other products, reducing the need for raw materials and minimizing waste.

- Q: Composite waterproof board, is the waterproof board and geotextile stick together call it?

- Yes. Now there are mainly adhesive technology, thermal composite process, Laminating process.

- Q: How do geotextiles help with load transfer in foundation systems?

- Geotextiles improve load transfer in foundation systems by distributing the load from the structure to a wider area, reducing the stress on the underlying soil and preventing soil settlement. They also help to reinforce weak or unstable soils, enhancing their load-bearing capacity and stability.

- Q: What are the limitations of using geotextiles?

- There are several limitations associated with using geotextiles. Firstly, geotextiles may not be as effective in controlling erosion on steep slopes or in areas with heavy rainfall. Additionally, they may not provide adequate support for heavy loads or traffic, making them unsuitable for certain construction projects. Geotextiles also have limited durability and may degrade over time, requiring frequent replacement. Finally, the cost of geotextiles can be relatively high, making them less affordable for some applications.

Send your message to us

Northwest Linings & Geotextile Polypropylene Nonwoven Geotextile Fabric Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords