Polyethylene Fiberglass High Strength Geogrid Geotextile USA Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

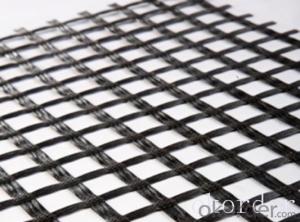

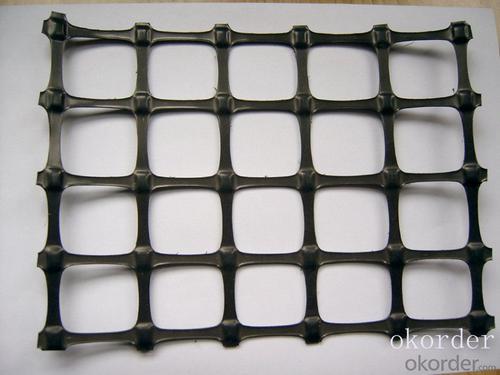

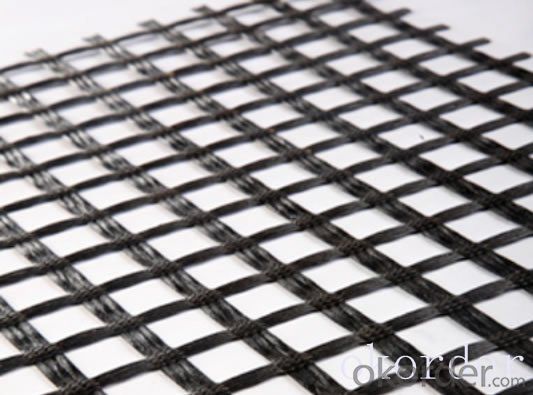

Biaxial

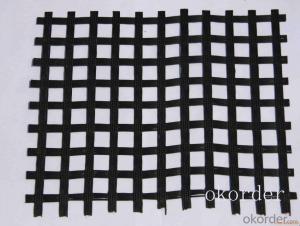

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

A geogrid is geosynthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Compared to soil, geogrids are strong in tension. This fact allows them to transfer forces to a larger area of soil than would otherwise be the case.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used for reinforcement of railway tracks?

- Yes, geotextiles can be used for reinforcement of railway tracks. Geotextiles are commonly used in railway engineering to improve track stability, reduce settlement, and increase load-bearing capacity. They are placed beneath the track ballast to distribute loads more evenly, prevent ballast contamination, and provide separation and filtration functions. Geotextiles can effectively enhance the performance and longevity of railway tracks.

- Q: Can geotextiles be used in the construction of golf course bunkers?

- Yes, geotextiles can be used in the construction of golf course bunkers. Geotextiles are often used as a lining material in bunkers to prevent contamination of the sand from the underlying soil and to enhance the performance and longevity of the bunker. They can help with erosion control, drainage, and stability of the bunker, ultimately improving the overall playing experience on the golf course.

- Q: Are geotextiles resistant to earthquakes?

- No, geotextiles are not inherently resistant to earthquakes. While geotextiles can provide benefits in terms of soil stabilization and erosion control, they do not have the ability to withstand seismic activity on their own. Additional engineering measures and materials are required to ensure structures are earthquake resistant.

- Q: what is the purpose of geotextile on gabion walls.?

- Geotextiles are fabrics associated with soil, earth or rocks. Gabions were earth filled barricades meant to halt enemy fire during battle. I'm guessing geotextiles on gabion walls more effectively hold back the earth or filler. They might have well suited permeability or retentive qualities for gabions. There are a few other definitions for gabions. But this is the militaristic definition. Gabions are also used in dams and such. In this case, geotxtiles might have good properties for being submerged in water and still retaining whats inside the gabions.

- Q: Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

- Q: How do geotextiles help in preventing soil liquefaction?

- Geotextiles help in preventing soil liquefaction by providing stability and reinforcement to the soil. They act as a barrier and restrict the movement of soil particles, thereby reducing the potential for liquefaction. Additionally, geotextiles enhance the drainage capacity of the soil, allowing water to flow through and preventing the buildup of excess pore pressure, which is a major factor leading to liquefaction.

- Q: Can geotextiles be used in stormwater management applications?

- Yes, geotextiles can be used in stormwater management applications. They are commonly used as part of the filtration and drainage systems to control erosion, separate different layers of soil, and enhance the overall performance of stormwater management systems. They help prevent clogging of drainage pipes and retain soil particles while allowing water to pass through, thus improving water quality and reducing the risk of flooding.

- Q: How do geotextiles reduce hydraulic pressure in soil?

- Geotextiles reduce hydraulic pressure in soil by allowing water to flow through them, while retaining soil particles. This helps to create a drainage pathway, preventing water buildup and reducing the pressure exerted on the soil.

- Q: Filament spunbond nonwoven geotextile performance requirements for what is the basic item

- Filament spunbond acupuncture non-woven geotextile is the implementation of the national standard GB / T-2008 standard. GB / T-2008 standard for filament spunbond acupuncture non-woven geotextile performance requirements of the basic items include: product vertical and horizontal nominal fracture strength (KN / m), vertical and horizontal nominal elongation at break (%) (KN), vertical and horizontal tearing strength (KN), mass per unit area deviation (%), width deviation (%), thickness (mm), vertical permeability coefficient (cm / s), equivalent pore size (O90 (95) / mm). Only the above indicators meet the corresponding GB / T-2008 standard requirements, be considered qualified filament spunbonded non-woven geotextile.

- Q: How do geotextiles help with erosion control in riverbanks?

- Geotextiles help with erosion control in riverbanks by providing a protective barrier that prevents soil erosion, while allowing water to flow through. They stabilize the soil, preventing it from being washed away by the force of the water, and also promote the growth of vegetation, which further helps to anchor the soil and protect against erosion.

Send your message to us

Polyethylene Fiberglass High Strength Geogrid Geotextile USA Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords