Polyester Material And Filament,DTY FDY POY Yarn Type polyester yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

Specification | 11-167dtex, 12-144F |

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

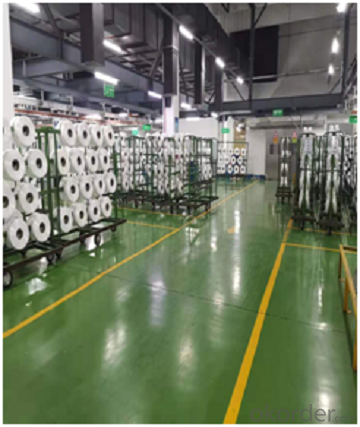

Production Facilities of FDY Yarn

We have the most advanced production system DSC. The whole production process is conducted and supervised by the operating platform. Meanwhile, there are 10 TMT fully automatic winding machine and Robot packaging system which highly improves the production efficiency and avoids manual mistakes.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

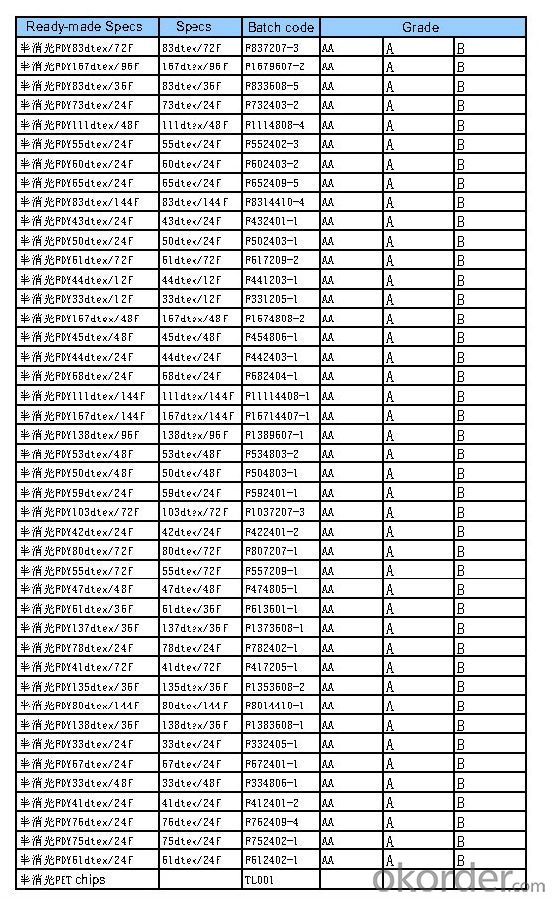

Regular Specifications

- Q: What does JC40S cotton yarn mean?

- Cotton yarn is made of cotton fiber by spinning the yarn, processed by the stock after the cotton thread. According to the different spinning process, can be divided into carded yarn and combed yarn.

- Q: In the textile fabric, mesh cloth and the difference between the Bali yarn is what

- In the textile fabric, the mesh cloth and the difference between the Bali yarn if the mesh-shaped small holes in the fabric can be used cotton or chemical fiber blended yarn (line) weaving, but also useful yarn and thread intertwined. There are white weave or yarn-dyed, but also a large jacquard, can be woven out of different patterns. Good ventilation, the dyeing and dyeing processing, cloth body very cool, in addition to summer clothing, especially suitable for curtains, mosquito nets and other supplies.

- Q: What is Artex and Artex Products?

- Artex is one of the major handicrafts exported in China, with annual exports of around US $ 300 million. According to statistics,

- Q: Will the following kind of yarn which fine? A32 support, B21 support

- At a nominal moisture regain, a 1-pound (453, 5g) heavy yarn length of 840 yards (one yard equal to 0,9144 m) is a multiple of 1 pound, which is just 840 yards long, ; 1 pound yarn length of 21 × 840 yards long, the fineness of the yarn 21, written for 21s

- Q: What is the number of yarns used in cotton textiles to mean what is meant

- Yarn is woven into a certain strength by the fineness, and can be processed into any length of material, it is the basic unit of fabric composition.

- Q: How to choose the twist of the roving?

- The roving strength increases with the increase of the roving coefficient, and the roving twist factor is increased to reduce the production efficiency of the roving machine, but it can increase the strength of the roving, reduce the roving elongation and improve the quality of the roving.

- Q: What are the benefits of the steaming machine to the textile industry?

- (2) the yarn is soft and reduces the wear of the needle; (3) from the beginning to the roll forming, always maintain a balanced and the best friction value; (3)

- Q: On the number of textile yarns

- Simply said that the length of the unit weight, the longer the length will be fine, so the greater the number of yarn the more thin!

- Q: What is the difference between mesh cloth and Bali yarn?

- It has a unique elasticity function. Mesh fabric mesh structure, in the production process after a high temperature stereotypes, when subjected to external forces, can follow the direction of force extension, when the pull force to reduce the withdrawal, the mesh can be restored to the original shape. Mesh cloth is made of tens of thousands of polymer synthetic fiber yarn, refined from the oil out. Made of knitted weave, it is not only firm, able to withstand high strength of the tension and tear.

- Q: Textile spinning mill management system

- Textile spinning mill management system "is a management software for textile spinning enterprises. Through the basic information, raw material management, production management, sales management, payroll management, account management, inventory management and statistical query eight functional modules To achieve the internal management of enterprises

Send your message to us

Polyester Material And Filament,DTY FDY POY Yarn Type polyester yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches