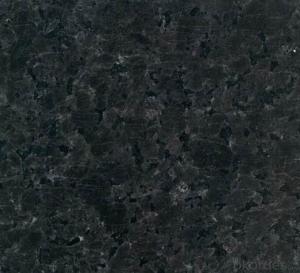

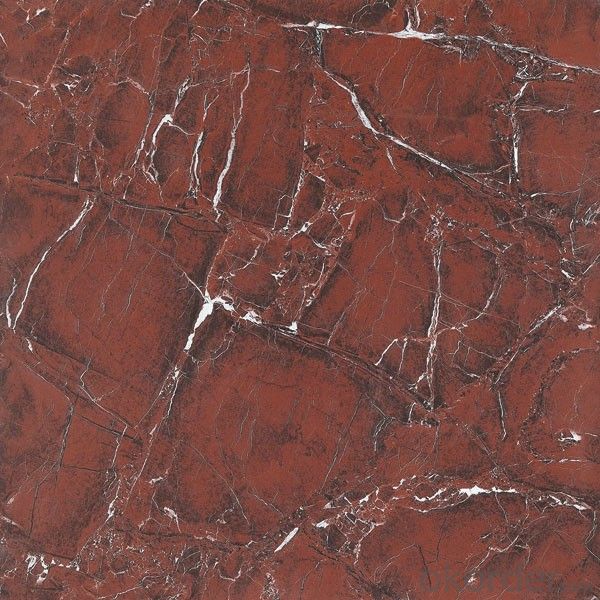

Polished Glazed Tile Black Stone CMAX 23301

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

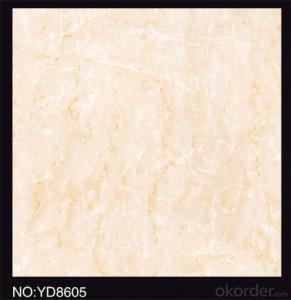

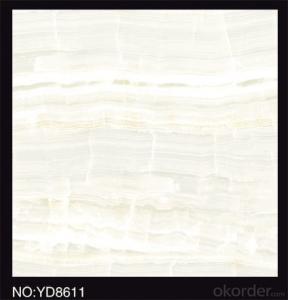

You Might Also Like

Key Specifications/Special Features of Glazed Tile :

1. Material: glazed porcelain

2. Antique feel, Metal Image

3. Low water absorption

4. Strong in hardness

5. Coordination in color and luster

6. Usage Area: home, office, hotel, government and corporate projects, flooring tiles, deluxe clubs flooring

7. Style: simple, classic, elegant and splendid in color

8. Good in abrasion and chemical corrosion-resistant

9. Resistance to thermal shock

10. Available in various sizes and colors

Primary Competitive Advantages of Glazed Tile :

1. All product of rustic ceramic tiles are of top grade AAAA

2. CE certificate, ISO9001:2008 and ISO14001:2004

3. OEM accepted.

4. Speial dimensions available according to your floor tiles request.

5. Best Quality with best price, strictly quality control.

6. On time delivery, in general 7-10days.

7. Best after sale service, customer can follow their porcelain tiles order situation any time. no matter on product line, warehouse or shipment.

Main Export Markets:

1. Asia

2. Australasia

3. Central/South America

4. Eastern Europe

5. Mid East/Africa

6. North America

7. Western Europe

Specification:

Tile type: | Ceramic tile |

Material: | Porcelain |

Size(MM) : | 600x600mm |

Thickness(MM): | 9mm |

Water Absorption: | ≤0.5% |

Color: | Available in all designs and colors |

Usage: | Used in floor |

Surface treatment: | Glazed surface |

Features: | Professional triple-burning in oven, which makes our tiles more excellent quality. |

Function: | Acid-Resistant, Antibacterial, Heat Insulation, Non-Slip, Wear-Resistant, Anti-fouling easy to clean |

Packaging: | 600x600mm: 4pcs/box,28kg/box,standard cartons and wooden pallets packing |

Remark: | All kind of designs can be produced according to your requirements |

Quality | |

Surface quality: | 95% tiles no defect from 0.8 away uprightly |

Breaking strength: | As require |

Resistance to thermal shock: | Without crack and flaw after 10 times anti heat shock test |

Brightness: | ≥55 |

Frost-resistance: | No crack or spalling after frost resistance test |

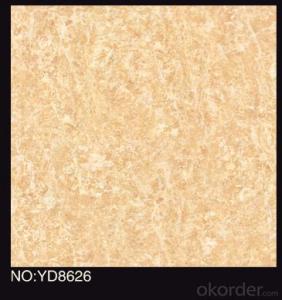

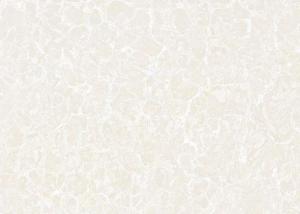

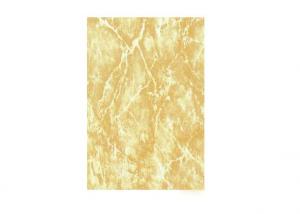

Product Picture:

Packing Pictures

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 960 Ctns/20’Fcl, 1382.4m2/20’Fcl

For 800x800mm, 3pcs/Ctn, 28 Ctns/Pallet, 616 Ctns/20’Fcl, 1182.72m2/20’Fcl

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q: I am looking to tile my livingroom/kitchen area appx 500sf. I am going with porcelain due to the strength ( i was told its better). My question is for resal (4-5 years) what is a better tile to lay; polished tile or regular glaze. I like the shiny clear coat look the polished has but someone mentioned it picks up footprints and it is not good for resale.Also, I was thinking that If I went with a larger tile, 18X18 or larger that it would look much cleaner with less grout lines, but since its only an area of 500sf that it would make my place look smaller than it is?any suggestions are helpful. Thanks

- A high sheen tile is going to give you a more formal look. A matte finish will be more casual. If you place the tiles on a 45 degree angle, the space will appear larger, but it will require more cuts and a little more tile. If you use 18 tiles and keep them squared with the room shape, the room will appear smaller. I am not a fan of big grout lines unless you are using Saltillo (Mexican) tiles. If you have the option of coloring the grout I would try to match the tile as closely as possible, unless you want to call attention to the grout.

- Q: It has been installed on a concrete slab for about five months now, could the slab not have cured right or is the tile layed wrong?

- here's the deal about laying tile over a concrete slab. either the tiler has to essentially build a floor over the slab (slab, then firring strips, plywood subfloor, thinset, backerboard, thinset, tile), or must use what's called an 'isolation membrane' to install the tiles directly on the slab (slab, then membrane, thinset, tile). the isolation membrane is a self-levelling rubbery substance that thinset can adhere to, that allows the slab to crack underneath without the cracks propagating upwards through the thinset and cracking the tile. if the tiler did neither, it's almost a guarantee that eventually the tiles over the slab will crack. (yes, if the slab had not fully cured, that might have caused the crack underneath; however, most all slabs will eventually crack even if everything else is perfect. that's the reason for the isolation membrane.)

- Q: I have 1in. tile all over my bathroom,is tthere a paint to use that will stay on?

- Yes, okorder ... You will get better results if you spray rather than brush it on. If you check it out, there a companies that specialize in doing this for you. The price isn't that bad. I had it done to a old cast iron tub with wonderful results.

- Q: I have painstakingly cleaned and restored victorian age tiles in hall (using natural and eco products). Wondering what to seal with? Found few eco tile sealants but wondered if anyone used any without distorting the colour? Thanks :)

- Most tile have a glazed finish so unless it dose not have it,it will be difficult to seal.You don`t mention wheat her its wall or floor tiles,if it wall tiles you might get away with it.If it floor tiles I think it will cause a problem by walk over it.

- Q: I would like to redo my entire house in ceramic tile floors but money is tight. I‘m planning to do the entire thing with leftovers I can get from other people who have finished their own tile projects. Is it possible ot use wall tiles on the floor for small areas? Are wall tiles able to withstand the pressure of walking? Any advice?

- just tell where you live and we all can visit you in hospital ..are you mad ?..do you want to throw money away ?..it will be like a skating rink ..you wont be able to stand up!...please ..go and have a lay down ..you will probably feel better tomorrow

- Q: Ready to buy tiles, no conditions to buy the brand, and we look at a British brand, I would like to ask these two models about how much the sale price? LC-8823 and ZC-8001

- Tell the landlord do not like to listen to, you said the brand I was in the tile industry for so long, I basically have not heard. The The The The It may be my personal ignorant it, Oh ~ ~ ~ ~ ~ ~ general you said the brand 800 * 800 market price (if the business is not black heart) probably: 25-40 between each piece, if beyond this price You buy it then. The The The The The Oh, if higher than the price of the proposed landlord to see: the new Pearl Group's brand, Mona Lisa, Hongyu, Enuo, the king, strong and other brands, are more reliable products in the end of the product.Or I answer those friends of those words: In fact, what brand is not important, it is important that you do not understand the tiles, teach some of the industry to identify tiles good or bad way, hope to help you:

- Q: i have just bought a house and my ceiling tiles needs cleaning. i would like to know if anyone out there knows what i can use to clean them. the ceiling tiles has dust but also has mildew on some of them. i don‘t want to replace them, i just want to clean them for now. thank you everyone.

- The one thing I can suggest to you is go to a place that deals with ceiling tiles and they will let you know what to use to clean them. I understand this a just for now project, but do consider what is the reason for the mildew even if you replace the tiles at a later date. If someone suggests to paint them then you're really going to have to ask the experts. If you use the wrong paint you can loose the acoustics. There are certain kinds of paints to use for ceiling tiles. I hesitate to tell you to use soap and water, because I don't know what the out come will be. It's like if you use too much of anything what will the results be. Same with soap and water regarding ceiling tiles. I may be making a mountain out of a mole hill, but I think you need to go to any hardware dept. that deals with ceiling tiles and get some straight answers before moving on, even if this is a temporary fix.

- Q: Can I use talavera tiles for this? The porch is concrete and was painted at one time. Looks like the last owners removed the paint, but then left it as is. Is talavera tile ok to use on an outdoor porch. I don‘t know much about it, I‘ve only seen pictures and think it‘s beautiful! Thanks!!

- any tile you like is okay to use. my advice would be to prepare the surface by cleaning it thoroughly then using a concrete adhesive before setting your tile with white thinset mortar. after grouting , be sure to use a sealer to prevent moisture getting under the tiles. the sunlight will expand the water and cause vaporlock that will pop your tiles. then maintain by resealing at least once ayear.

- Q: How to convert tiles how much money a square meter?

- The price of a piece of tiles divided by its side length is a square meter of the price, such as 80 * 80 brick 100 yuan is 100 divided by 0.8 divided by 0.8 = 156.25 a square meter

- Q: Does floor tile give a lot of heat? I want to get a tile substrate for my leopard gecko, but I don‘t know if it will get warm enough for him. I have an under tank heater, so if I put the tile in will the heat from the under tank heater block or go through the tile?

- I put a little layer of sand under my tiles to fill up any air spaces under the tiles (as they're textured to hold grout). Tiles heat up and hold heat a LOT better than pretty much any other substrate. If you want some really neat tiles, try slate. They are really natural, come in awesome colors naturally and hold heat just as well as other tiles. But there are some really nice ceramics, too. Just don't get anything overly glazed.

Send your message to us

Polished Glazed Tile Black Stone CMAX 23301

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1325 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches