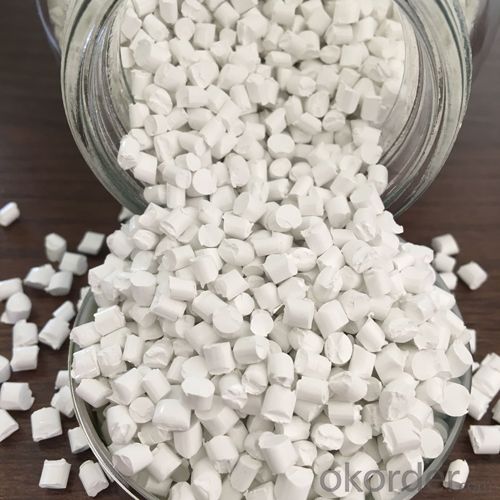

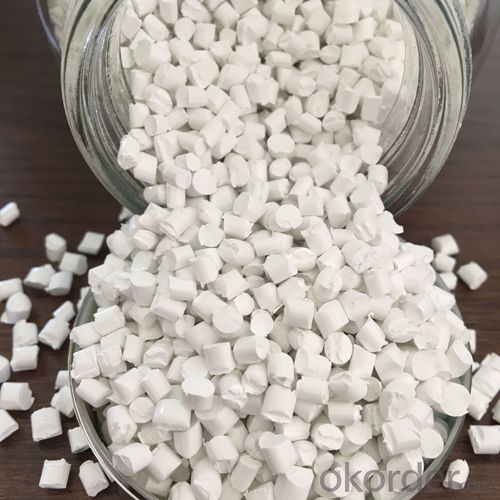

Plastic White Masterbatch Color & Additive Master Batch for Film PPR Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White masterbatch is made of imported Tio2 and virgin pe resin and additives production

Effect:High covering,spread evenly,strong tinting strength

Additive amount:2%-10% amount is recommened.Or adjust the dosage as per your products performance

Application:blowing film,casting film,packing film,PP-R Pipe,ect

Packaging:Paper-plastic compound bags,or PE bags,25kg net weight/bag.

Advantage of White Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of White Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

Product Pictures of White Masterbatch

- Q: Plastic pipe gas temperature 150 degrees, plastic pipe surface problems?

- Plastic pipe is usually plastic resin as raw material, adding stabilizers, lubricants, etc., to "plastic" method in the pipe mill by extrusion processing. Because of its light weight, corrosion resistance, beautiful appearance, no bad smell, easy processing, convenient construction and other characteristics, it has been more and more widely used in building engineering. Mainly used for building construction of the water supply system, piping, drainage, exhaust and sewage sanitary pipe, underground drainage pipe system, storm pipe and wire installation supporting the use of threading tubes, and so on.

- Q: Is the plastic with high melting index good?

- The melt index, the full melt flow index, or the melt flow index, is a numerical value that indicates the fluidity of the plastic material when it is processed.

- Q: What material is the disc made of, metal or plastic?

- The CD disk has a substrate thickness of 1.2mm, a diameter of 120mm, a hole in the middle, and a circular shape. It is the shape of the disc. The reason why the disk can be taken at will depends mainly on the hardness of the substrate.

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- EPS is a foaming agent that is used to make foam, which is the white foam that is packed in the TV and refrigerator.

- Q: What are the raw materials for making plastics?

- Polymer: any of the pure or polymeric materials produced by the polymerization process, whether natural or synthetic resins, are polymers, polymers, or polymers

- Q: What are the plastic raw materials?

- 1, general plastics (polyethylene, polypropylene, polyvinyl chloride, polystyrene, ABS, etc.), thermosetting plastics (phenolic resin, epoxy resin, unsaturated polyester, polyurethane, silicone, amino resin, etc.);2 thermosetting plastics (phenolic resin, epoxy resin, unsaturated polyester, polyurethane, silicone, amino resin, etc.);3, thermoplastic engineering plastics (polyamide, polycarbonate, POM, PET, PBT and other plastics)

- Q: What are the main biodegradable plastic bags made of?

- The degradable plastic bags made of polyethylene and starch, but this can only be degradable plastic plastic degradation into smaller chunks of plastic, plastic compositions did not completely disappear, so its degradation is limited.

- Q: What are the raw materials needed for producing plastic hair dryer shell and flashlight shell?

- Water absorbency. Nylon has high water absorption, and saturated water can reach more than 3%. To a certain extent, the dimensional stability of the parts is affected

- Q: What kind of raw material is plastic hollow board made of?

- Plastic hollow board products widely, can produce hollow board turnover box, hollow board, hollow plate knife clapboard, anti-static hollow board, conductive plastic hollow board products. Multi use in electronic products turnover and handling, warehousing and so on. In addition to the production of flame retardant plastic hollow board, plastic plastic hollow board, back board, magnetic refrigerator with black and white writing board, backplane cloth cabinet inside the closet board and other plastic products.

- Q: Chemical, plastic raw materials, plastic raw materials how sub grade?

- Plastic bucket is usually added to the resin, in the production of lubricants, plasticizers, dispersant, pigment, polyethylene wax, and these materials good variety, price range, and some high melting point, good whiteness, production out of the finished product is good texture, high brightness, good conscience manufacturers add some heat thermoplastic elastomer, feel very well; and a point of the raw materials, the relative performance is low, the production of plastic barrels must be of poor quality.

Send your message to us

Plastic White Masterbatch Color & Additive Master Batch for Film PPR Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords