Plastic Tubes - PPR Pipes and Fittings for Agricultural Application from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

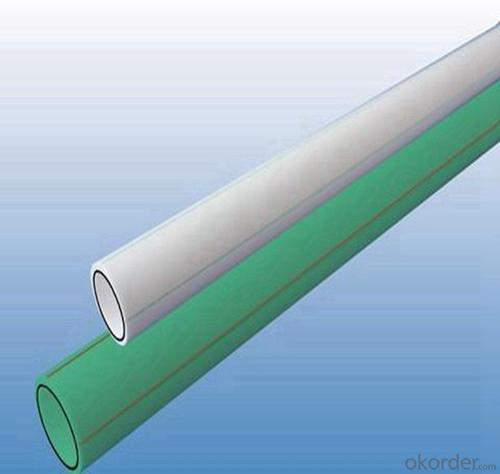

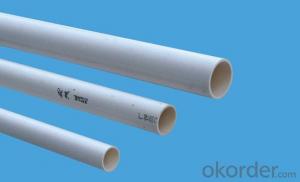

Material: Plastic

Technics: injection

Place of Origin: China (Mainland)

Connection: Welding

Head Code: round

Color: white

Type: Pipes

Model Number: DSW382-383

Shape: Equal

Product Applications:

1.Potable water for cold and warm water installations

2.For rainwater utilization systems

3.For compressed air plants

4.For solar plants

5.For agriculture and horticulture

6.Heating pipes for residential housing

7.For industry

Advantages:

1.We named this kind of fittings as PPR reducing sleeve. ppr reducing coupling

2.A whole part of this PPR reducing sleeve is made of polypropylene.

3.As you know, all the fitting designed for connecting the pipe or change the piping path. This PPR reducing sleeve is able to connect the different diameter pipeline together. I believe you know how to use it.

4.All of these PPR pipe fitting come in 3 different colors: white, gray, green.

5.Our PPR pipe fitting had been pasted the ISO9001 authentication. And had been got the CE certification.

6.We adopt the newest technology in the piping produce industry.

Why Us?

1.We can make any requirements in design, pattern, color and size.

2.We can make customer's logo on the surface of products.

3.The dimension tolerance of our products is controlled within 0.03mm.

4.Our products are child safety, pet safety and environment-friendly.

Product Show:

- Q: What are the environmental implications of using plastic tubes?

- The environmental implications of using plastic tubes are significant. Plastic tubes are typically made from non-biodegradable materials like polyethylene or polypropylene, which means they can persist in the environment for hundreds of years. Improper disposal of plastic tubes, such as littering or landfilling, can lead to pollution of land and water bodies. They can also contribute to the growing problem of plastic waste in oceans, harming marine life through ingestion and entanglement. Manufacturing plastic tubes requires the extraction of fossil fuels and the emission of greenhouse gases, contributing to climate change. Additionally, the production process involves the use of chemicals and energy, further depleting natural resources and increasing carbon footprints. Considering these environmental impacts, it is crucial to explore alternative materials or recycling options to mitigate the harmful effects of plastic tubes.

- Q: What are the advantages of using plastic tubes over other materials?

- There are several advantages of using plastic tubes over other materials. Firstly, plastic tubes are lightweight, making them easy to handle and transport. Secondly, plastic is a durable material that can withstand various environmental conditions, such as moisture and temperature changes. Additionally, plastic tubes are resistant to corrosion, which makes them ideal for use in industries like plumbing and agriculture. Furthermore, plastic tubes are cost-effective, as they are often cheaper than other materials like metal or glass. Lastly, plastic tubes can be easily molded into different shapes and sizes, offering versatility in design and application.

- Q: Are plastic tubes suitable for use in food and beverage industries?

- Yes, plastic tubes are suitable for use in food and beverage industries. They are commonly used for packaging, transportation, and storage of various food and beverage products. Plastic tubes are lightweight, durable, and resistant to chemicals, making them a hygienic and cost-effective choice for the industry. Additionally, they can be customized to meet specific requirements such as size, shape, and material composition, ensuring the safety and quality of the products.

- Q: What are the advantages of using plastic tubes in the electrical packaging industry?

- There are several advantages of using plastic tubes in the electrical packaging industry. Firstly, plastic tubes are lightweight, making them easy to transport and handle. Secondly, they provide excellent insulation properties, protecting electrical components from damage and ensuring safety. Additionally, plastic tubes are durable and resistant to corrosion and moisture, making them suitable for various environments. They are also cost-effective compared to other materials, allowing for lower production costs. Lastly, plastic tubes can be easily customized in terms of size, shape, and color, providing flexibility in design and meeting specific packaging requirements.

- Q: Can plastic tubes be used for oil and gas industries?

- Yes, plastic tubes can be used for oil and gas industries. They are commonly used in various applications such as transportation of fluids, chemical injection, and well monitoring. Plastic tubes offer advantages such as resistance to corrosion, lightweight, and cost-effectiveness, making them suitable for specific oil and gas industry requirements.

- Q: Are plastic tubes FDA-approved for food contact?

- Yes, plastic tubes can be FDA-approved for food contact, but it depends on the specific type of plastic used and its compliance with FDA regulations for food safety.

- Q: I want to connect some aquarium tubing to a regular plastic bottle, somewhere on the side, low down. It has to be a water and air tight connection and the bottle will contain water that will be drank so if any apoxies are used they have to be safe.How would you do it?

- Go to the hardware store, get a brass reducing bushing, one that your hose will fit into, get some o-rings, and a flare fitting, one that your hose will fit in, and try this. Push your hose up through the plastic bottle put the brass reducing bushing on it then pull it through the hole in the bottle, put the ring inside the bottle between the reducing bushing and the bottle, then screw your flare fitting on the bushing, and it should hold and be water tight.

- Q: Can plastic tubes be customized?

- Yes, plastic tubes can be customized. They can be manufactured in different sizes, shapes, and colors to meet specific requirements. Additionally, various features such as printing, labeling, and embossing can be added to personalize the tubes.

- Q: Can plastic tubes be used for craft projects like DIY lamps?

- Yes, plastic tubes can be used for craft projects like DIY lamps. They can be easily cut, shaped, and manipulated to create unique lamp designs. Additionally, plastic tubes are lightweight, durable, and come in various sizes and colors, making them a versatile material for crafting.

- Q: How are toothpaste tubes made? I know that there's polyethylene coatings on aluminum, but how to they actually made the tubes this way? I know it can't be injection molding or blow molding.

- why can't it be injected extrusion molding of the tubing followed by a bonding process?

Send your message to us

Plastic Tubes - PPR Pipes and Fittings for Agricultural Application from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords