Plastic Tubes PPR Fitting Elbow with Unequal Diameter Food Hygiene Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9100 pc

- Supply Capability:

- 520000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

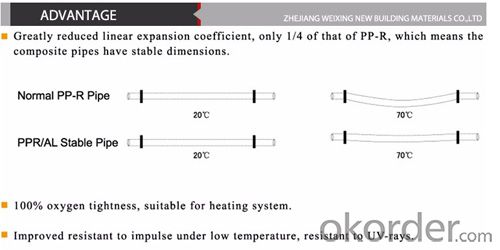

Advantages of PPR pipe

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

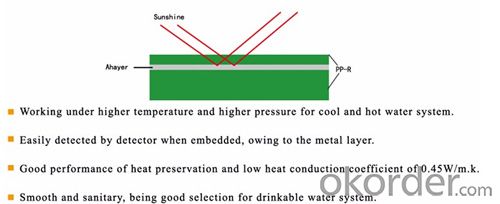

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

FAQ

Features of PPR Pipes

PP-R pipe as a new pipe, has the following characteristics:

1. The production of energy saving PP-R pipe is only 20% of the steel pipe, and its low thermal conductivity [0.2W / (mK)], is only 1/200 of steel pipe, used in hot water systems will be greatly reduced heat loss.

2. Corrosion-resistant, non-scaling, hygiene, wall using non-toxic PP-R pipe can be removed from the use of galvanized steel pipe caused by fouling, rust and water quality caused by the "secondary pollution." Since PP-R component simple, basic component of carbon and hydrogen, in line with food hygiene regulations, non-toxic, more suitable for transporting drinking water.

3. Heat, pressure, long life and long-term use temperature of PP-R pipe up to 95 ℃, short-term use temperature up to 120 ℃. The temperature is 70 ℃, working pressure of 1.2MPa conditions, the long-term continuous use, life expectancy up to 50 years.

4. Lightweight, high strength, fluid resistance PP-R pipe density of only 1/8 of metal pipes, pressure resistance strength test up 5MPa, and good toughness, impact resistance. The smooth wall has no rust, no scaling, fluid resistance. The main technical indicators PP-R pipe is as follows: the density of 0.9g / cm3 modulus of elasticity (20 ℃) 800MPa thermal expansion coefficient of 1.8 × 10-4 / K thermal conductivity of 0.2W / (mK) longitudinal shrinkage rate of 2% impact ≤10% hydraulic test short-term trials breakage rate 1h, ring stress 16MPa no leakage long 95 ℃, 1000h, hoop stress 3.5MPa no leakage table 1 performance comparison of several pipe material.

PP-R pipe in addition to general plastic pipe has a light weight, corrosion-resistant, non-scaling, long life and other characteristics, but also has the following main features:

1. Non-toxic, health. Molecular material PP-R only carbon and hydrogen elements, no harmful toxic elements are present, reliable health, not only for hot and cold plastic water pipe, can be used to clean drinking water systems.

2. Thermal insulation. PP-R pipe thermal conductivity coefficient of 0.21w / mk, steel is only 1/200.

3. Good heat resistance. Vicat softening point of PP-R pipe 131.5 ℃. Maximum operating temperature of up to 95 ℃, plastic water pipe can meet the water supply and drainage requirements specification hot water system.

4. Long service life. PP-R pipe in working temperature 70 ℃, working pressure (P.N) 1.OMPa conditions, the service life of up to 50 years; at room temperature (20 ℃) the service life of up to 100 years.

5. Easy PPR installation, reliable connection. PP-R has good welding properties, pipe, pipe fittings can be used hot-melt and fused connections, easy PPR installation, the joint firm, which is greater than the strength of the connection portion of the strength of the pipe itself.

6. Recyclable materials. After cleaning, after crushing PP-R waste can recycle in pipe, tube production. If recycled material amount does not exceed 10% of the total, does not affect pp-r pipes and fittings product quality.

- Q: 1995 Honda Civic1.6L V-TECH Motor v4This is a good car there is only one problem the engine overheated and melted the plug wires. I replaced the Part but needs to have plug tubes cleaned out due to melted plastic. I need help from a mechanic expert about this as i do not have the tools to do the job but i could get them tools.

- unless the melted plastic interferes with the new tubes or spark plugs, there is no reason to try to clean the plastic out. if you can get the plugs out and put new ones in and put the wires on with no problem then just leave the residue in there...it won't hurt anything. you are talking about a major undertaking if you want to remove the tubes to clean them. The valve cover has to come off to get to the tubes and the tubes are usually pressed into the base of the head so the head may have to come off as well. you might want to just pull the wires and try to use a rat-tail file down into the tube to scrape away the excess plastic on the inside of the tube (leave the spark plugs in place if you try this so the filings don't get into the engine). Then use a vacuum cleaner to suck the filings out of the tube before you put the wires back on. I'd recommend that as the best thing to do if the burnt plastic is a concern. Otherwise, I'd leave it alone. hope that helps

- Q: What are the common wall thicknesses for plastic tubes?

- The common wall thicknesses for plastic tubes vary depending on their intended use and the specific industry. However, some typical ranges for plastic tube wall thicknesses include 0.5mm to 3mm for general-purpose applications, while thicker tubes ranging from 3mm to 6mm or more are often used for structural or heavy-duty applications.

- Q: I've usually see em in the movies and stuff like that. Little long tubes like hand held flares which upon breaking or twisting emits faint green light sort of like the radium stickers and stuff like that and are these available in military surplus stores?

- Here in NZ I think they're called cyanolume sticks. They're widely available in shops and they're useful in civil emergency kits, along with candles and a torch. They're useful as a replacement for a torch where there's flammable vapour and you don't want sparks. They get their name from the colour of the light they emit; cyan, or blue-green.

- Q: Im making moonshine but not for drinking for fuel. I know that its a bad idea to distill with plastic if your gonna drink it but will it be ok for fuel?

- I wouldn't Plastic is made of hydrocarbons, and alcohol is a hydrocarbon - under the chemical principle of like dissolves like I would think the alcohol could leach chemicals in the plastic or dissolve it. If you leach extra chemicals it ruins yer shine!

- Q: What are the advantages and disadvantages of PPR plastic pipes compared with steel pipes?

- Power cost;4, corrosion resistance: with good acid, alkali, chemical resistance, electrical resistance, good corrosion resistance, the use of pitting will not occur;5 、 easy to install: flexible connection, rubber ring seal, easy installation, good sealing;6, long life: under normal working conditions, the service life of up to 50 years;7, non-toxic hygiene: in line with drinking water standards, the transmission of water from the two pollution;8, low cost: transportation and installation costs low, material costs cheaper, the total cost of the project than the cast iron pipeline savings of 30%.

- Q: he said something about the pressure. That being the reason he had to get new tubing.

- First okorder and type in your car and it will and you can do a search for a fuel pump and it will show you a picture and print it out and take it with you then you will know if he is trying to take your money or not I have done a few and I have never had a problem like you describe

- Q: Are plastic tubes FDA-approved for food contact?

- Yes, plastic tubes can be FDA-approved for food contact. However, it is important to note that not all plastic tubes are FDA-approved, as specific requirements and regulations must be met to ensure their safety for food contact.

- Q: now don't tell me to go to he** or mind my own business.....I know there are alot of horse people on here......but I was just wondering if there are any on here who would question the human-ness of working these horses until they are panting and snorting and jumping.....and some missing the jumps and smashing their hooves into hard plastic tubes? Just curious.........Just want honest opinions............I really don't think, in my opinion (and everyone is entitled to their own) that many of these horses even want to be there.......(at the shows).........thanks for answering

- Not being mean or anything... But would you please gets your facts straight before you judge something. The pastic tubes aren't attatched to the poles. they are on cups so that when they are bumped they give and fall down. Leg protection is used almost all the time... to PROTECT the horse. If the horses didn't want to do it... they wouldn't! They can be very stubborn creatures at times.. you can't make them do something they REALLY don't want to do. And you make it sound like these horses are soo abused?? Most of these horses are very expensive and are pampered BEYOND BELIEF!!! And about the panting, snorting, jumping... Don't you start breathing harder and sweating after a work out!!! It works the same for horses.... That's my opinion. I am not a jumper, I am a barrel racer!!!!! Jumped horses before but i prefer the something faster! It is not inhumane at all! Most (i know there are exceptions... some people who are in it for the money... the championships... the wins and dont' care about the horse but its not common) They are very pampered, very well cared for PETS!!! They are expensive!!! I wonder if you are a horse owner of have ever been to a show jumper competion. What makes you think it is soo bad?? (and about the falling... dont even the best human athletes have falls or spills? As for the horses having control over the situation.. they have none. Those are the risks you take... i guarantee they are well looked after to make sure they are ok!) Good Day! **Edit** Sasha... are you freakin NUTS!!! You don't like seeing ASSISTANT dogs because they always look sad? What do you think that theyre abused because they are giving back freedom and life to the people they help?... Give me a freakin break!!! ... what has this world come to!!!! DELTA_DAWN I GIVE YOU MAD PROPS!!!!!! VERY WELL SAID!!!! I'd give you more than one thumbs up if i could!

- Q: What industries commonly use plastic tubes?

- Plastic tubes are commonly used in a wide range of industries, including pharmaceuticals, food and beverage, cosmetics, medical, plumbing, construction, and automotive.

- Q: The ones I'm talking about are the ones with loose caps

- What they mean by sterile is that when they were produced they were either put under a UV light or place in a high temperature vat. So by the time they are place in the packaging they are sterile. When you open the package it is up to you to keep the environment that you are working in sterile. When the caps are tight, it should be an air tight seal lowering the change of contamination.

Send your message to us

Plastic Tubes PPR Fitting Elbow with Unequal Diameter Food Hygiene Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 9100 pc

- Supply Capability:

- 520000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords