Plastic Sheets - High Density PVC Foam Sheet / Board for Sign & Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Material Introduction:

PVC is a strong, stiff, low cost plastic material that is easy to fabricate and easy to bond using adhesives or solvents. It is also easy to weld using thermoplastic welding equipment. Guangzhou Engineering Plastics Industries (Group) Company has studied and applied this material in many industries for many years. And we know that PVC Sheet and Rod has an exceptional chemical resistance and has high mechanical and tensile strength combined with a high degree of stability which together makes this easily welded product one of the most versatile general purpose plastics available.

2. Material Introduction:

Good surface brightness ,Anti-crack, Impact-resistant

Excellent strength and toughness performance

Flame retarded

Weather resistant,water proof, acid proof, Resistant to chemicals and corrosion., Abrasive-resistant , Excellent UV resistance

Aging-resistant

3. Application:

Construction materials, industrial engineering, semiconductor processing equipment.

Machining: Cutting, sawing, turning, drilling, planing, milling, grinding & screwing.

Forming; Stretch forming, thermoforming, vacuum forming, blow moulding, bending, folding & punching

Welding;Hot-gas, heated-tool & folding.

Eviroment protection,chemical industry,mentallurgy of rare metals, extraction work of rare earth,

Stationery

Package

4. Main Properties of PVC:

1 | Size | 1000x2000mm, 1220x2440mm, 1500x3000mm, etc. |

2 | Thickness | 0.3mm to 60mm |

3 | Width | max 2000mm |

4 | Length | any length |

5 | Density | 1.45g/cm3 |

6 | Material | Polyvinylchloride (100% Virgin PVC Raw Material) |

7 | Type | Rigid PVC Sheet |

8 | Color | Clear, white, black, dark grey, light grey, green, blue, yellow, etc. |

9 | Surface | Smooth ,clean. |

10 | Type | Sheet and Roll are available |

11 | Certification | ISO9001:2000, RoHS |

12 | Packing | Inner packing: Plastic bag; Outer Packing: Carton |

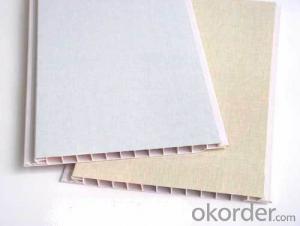

5. Pictures:

- Q: Can plastic sheets be used for greenhouse insulation?

- Yes, plastic sheets can be used for greenhouse insulation. They are often used as a cost-effective option to retain heat and provide insulation in greenhouses.

- Q: Is the extrusion plate the same as the foam board?

- Extruded board: the polystyrene resin and additives by extrusion process manufacturing have continuous uniform surface and obturator honeycomb structure plate some honeycomb structure is totally void of a plate type structure with obturator insulation materials (150-500Kpa) have the same pressure with low thermal conductivity values (only 0.028W/ M.K) has excellent insulation failure compressive strength compressive properties of 220-500Kpa

- Q: Nascar: true paint or plastic sheet?

- Nascar Vinyl Wrap

- Q: How should the plastic cutting boards be cleaned?

- Sunshine disinfection: the sun's ultraviolet rays kill bacteria, or do not run out of clean cutting boards should be placed in the sun exposure, so that not only can kill bacteria, and can make the block dry, reduce the bacterial reproduction.

- Q: How are plastic sheets manufactured?

- Plastic sheets are manufactured through a process called extrusion. In this process, plastic pellets or granules are melted and then forced through a die, which is a specially shaped opening. The molten plastic is then cooled and solidified to form a continuous sheet. The thickness and width of the sheet can be adjusted by changing the size of the die opening.

- Q: We are using this for a slip and slide at a camp and need some plastic that is sturdy and will withstand many kids going down it. 6 mil is the minimum, but 8 to 10 mil is prefered and it needs to be about 40 ft x 100 ft. We'd prefer no black, as it will be super hot in the sun. I have already called a few local farm stores, Lowes, and Home Depot. Are there any places that I may have forgotten?

- 10 Mil Plastic Sheeting

- Q: PVC floor, plastic flooring, coil flooring, floor leather, floor gel difference?

- Difference:1, plastic floors, floor boards and PVC floors are of the same floor.2, coil flooring, floor leather is the same kind of material.

- Q: Put drops of water on glass or plastic sheet. After evaporation we see white soft dust there. What's that?

- If it was pure water, and there was no dust present in the room there should be no dust. But if it's tap water that is most likely lime deposits or deposits from the minerals in the water. Try the same experiment with distilled water (not bottled drinking water, because minerals are added).

- Q: What are the installation methods for plastic sheets?

- There are several installation methods for plastic sheets, including adhesive bonding, mechanical fastening, and heat welding. Adhesive bonding involves using an appropriate adhesive to secure the plastic sheet to the desired surface. Mechanical fastening involves using screws, rivets, or other fasteners to secure the sheet in place. Heat welding is a method that uses heat to create a strong bond between the plastic sheet and the surface it is being installed on. The choice of installation method depends on factors such as the type of plastic sheet, the intended use, and the specific requirements of the project.

- Q: It's flat, like paper, but with a layer of plastic over top of it that has grooves into it that refracts the image printed on the paper. You used to get them in cereal/crackerjack boxes, or printed on a child's plastic ruler, or sometimes even the cover of a book would have them. Depending on the angle that you hold them, you see different images. You could tip them back and forth to produce a little 5 or 6 frame animation. Or some of them even let you see some basic 3D stereoscopic images. You don't need to wear 3D glasses or anything, it's just a flat thing.What's that technology called? I'm trying to find info about them and I don't know what they're called. Is there a company that will make them for me?

- It's called autostereoscopy. The grooved plastic is either a lenticular lens or parallax barrier

Send your message to us

Plastic Sheets - High Density PVC Foam Sheet / Board for Sign & Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords