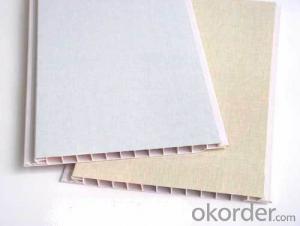

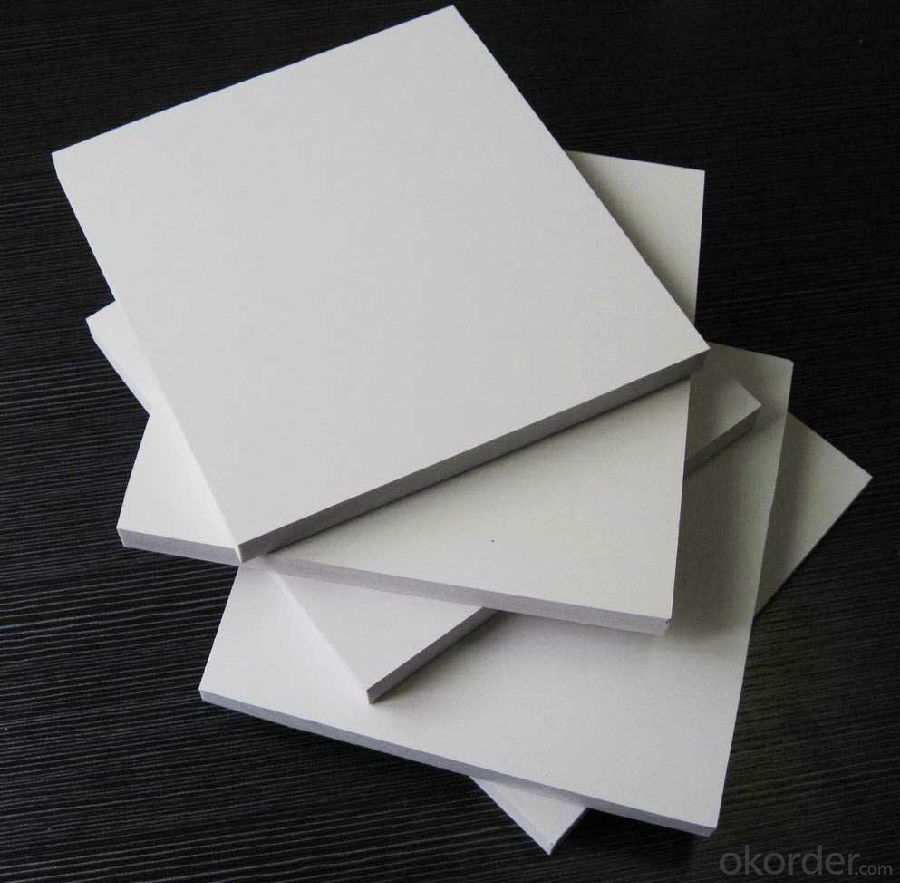

Plastic Sheets - High Density PVC Foam Sheet / PVC Rigid Board / Forex PVC Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

high density PVC foam sheet / PVC rigid board/ forex PVC board

Description:

PVC FOAM SHEET, is a new type of environmental protective plastic material instead of woods and steels.Its main material is PVC, shaped through foaming and pressing with additives. It covers not only the features of wood plast but also itself's other features.

Features:

1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

Usual Dimensions/Size of our PVC foam board :

1220mm*2440mm

1560mm*3050mm

2050mm*3050mm

Standard Width: 1220mm, 1560mm, 2050mm

Length: could be customized or cut according to your request

Usual Thickness of our PVC foam board : 1mm-30mm

Color: White,Black,Green,Red, Yellow, Blue, etc.

| Physical Properties: | ||

| Items | Unit | Value |

| Density | g/cm3 | 0.30-0.90 |

| Compressiove Strength | Mpa | 12-20 |

| Fexural Strength | MPa | 12-18 |

| Fexural Strength | Mpa | 800-900 |

| Impact Strength | KL/m2 | 8-15 |

| Fracture Elongation | % | 15-20 |

| Shao Scale | D type | 45-50 |

| Water Absorbing Rate | % | ≥1.5 |

| Vicat Softening | ℃ | 73-76 |

| Self-extinguishing Level | ≤5 seconds | |

FAQ

Q:Would you please tell me the company have business relations which countries?

A:Our products are exported to North America, South America, Europe, the middle-south Asia, the Middle East, etc., and have good market in these places.

- Q: Are plastic sheets resistant to punctures from sharp tools?

- Yes, plastic sheets are generally resistant to punctures from sharp tools. However, the level of resistance may vary depending on the thickness and type of plastic used.

- Q: Can plastic sheets be used for packaging fragile items?

- Yes, plastic sheets can be used for packaging fragile items. They provide a protective barrier against external forces and help prevent damage during transportation or storage.

- Q: How do plastic sheets compare to polycarbonate sheets?

- Plastic sheets and polycarbonate sheets have some similarities, but there are also significant differences between the two materials. Plastic sheets refer to a broad category of materials such as acrylic, PVC, or HDPE, while polycarbonate sheets are a specific type of plastic sheet. In terms of strength and durability, polycarbonate sheets outperform most traditional plastic sheets. Polycarbonate is known for its exceptional impact resistance, making it virtually unbreakable. On the other hand, regular plastic sheets may be more prone to cracking or breaking under stress. Another significant difference is transparency. Polycarbonate sheets are generally more transparent than most plastic sheets, allowing for clearer visibility. This trait makes them suitable for applications where optical clarity is crucial, such as in windows or protective barriers. However, plastic sheets have their own advantages. They are often more cost-effective compared to polycarbonate sheets, which can be a significant factor in certain projects or applications. Additionally, plastic sheets come in a wider range of colors and finishes, allowing for more design options. Ultimately, the choice between plastic sheets and polycarbonate sheets depends on the specific requirements of the application. If strength, impact resistance, and optical clarity are top priorities, polycarbonate sheets are the preferred choice. However, if cost, color options, or specific material properties are more important, traditional plastic sheets may be a viable alternative.

- Q: im currently decorating one of the bedrooms of the house im living in, and have set my self on having a big stencil design, roughly abut 6 ft x 4 ft but i need a sheet of plastic to be able to make the stencil, any ideas as to where i could find something like this?

- They seem to have the effect of stopping the letters moving around. It's just the way that some dyslexics brain's work.

- Q: Can plastic sheets be used for room divider partitions?

- Yes, plastic sheets can be used for room divider partitions. They are lightweight, easy to install, and offer privacy. Additionally, plastic sheets come in various colors and designs, allowing for customization and aesthetic appeal.

- Q: How much is the hanging plastic buckle?

- Plastic gusset plate ceiling material costs about 20 yuan a square meters, the main brands are different, different thickness, the price is also different. Labor cost is 12 yuan per square meter. It is not recommended to use a plastic gusset plate in the kitchen because it is flammable and easy to age.

- Q: What I mean is like, is there anything else besides white, translusant, black or clear sheets of shrinky dinks/shrinkable plastic.And if so, where can a purchase them?

- Are you talking about Shrink Wrap? If you are, yes they do. I've used green and red at christmas time and I used purple for a bridal shower a few weeks ago. Go to your local craft store and ask them to point you toward the shrink wrap.

- Q: I want to put a layer of pretty pebbles on top of something. I thought plastic sheet, but that will accumulate rainwater. I can't just put the pebbles on bare earth, because weeds will work their way up between the pebbles.

- For smaller rolls of weed block you might get it at the dollar store. For larger rolls try a home renovation store or a big box store. It's fabric in a roll. I suggest 2 layers. Tuck in the edges so that no weeds grow along the edges. As it is a fabric it will let the water seep through.

- Q: Where can i buy big sheets of Coroplast?

- I okorder / ... HTH, Diane B.

- Q: Can plastic sheets be used for protective packaging?

- Yes, plastic sheets can be used for protective packaging. They are commonly used to wrap and protect various items during storage, shipping, or transportation. Plastic sheets provide a barrier against dust, moisture, and other potential damages, ensuring that the contents remain safe and intact. Additionally, plastic sheets can be easily cut and shaped to fit different objects, making them a versatile option for protective packaging.

Send your message to us

Plastic Sheets - High Density PVC Foam Sheet / PVC Rigid Board / Forex PVC Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords