plastic masoneilan control valves 1/8'' inch

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Standard or Nonstandard: | Standard | Structure: | Control | Pressure: | Medium Pressure |

| Power: | Solenoid | Material: | Plastic | Temperature of Media: | Normal Temperature |

| Media: | Water | Port Size: | 1/8" | Place of Origin: | Zhejiang China (Mainland) |

| Model Number: | DSF-1/8-FF-A | Brand Name: | masoneilan control valves | Color: | Customised Pantone Color |

| Holding Power VA: | 5.5VA | Certification available: | Yes | Sample Time: | 3-5days if you want to customize your logo |

| MOQ: | 200pcs | Logo: | Any printing we can make for you just send the design to us! | OEM: | Professional OEM manufactory |

| Holding current: | 0.18A/24VAC | Voltage: | 12/24VAC, 12/24VDC, 6-40VDC,110VAC and 220VAC with solenoid |

Packaging & Delivery

| Packaging Detail: | 20PCS/CTN |

| Delivery Detail: | 35 days (according to the order quantity) |

Specifications

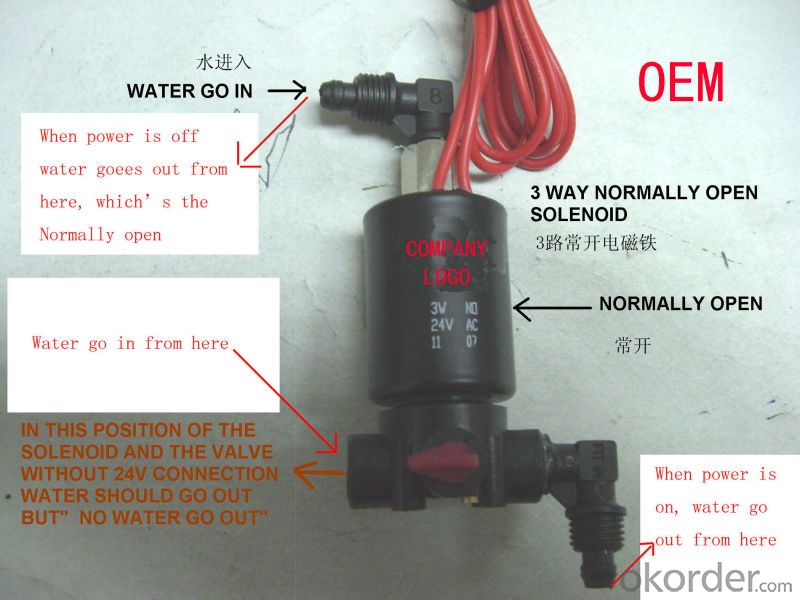

masoneilan control valves DSF-1/8-FF-A in 1/8" inch size

Control by the irrgation solenoid to on-off the valve

OE

masoneilan control valves : DSF-1/8-FF-A

Economical irrigation valve designed primarily for the residential and light commercial use, and it features solid construction, convenient operation and reliable performance. This solenoid valve series have 3 options: without Manual, or with Manual, or with flow control, for each type, they can be matched our irrigation solenoids (S391 series plastic encapsulated & S392 series metal shell) produced by our company at the voltage of 6-40VDC latch, 12/24VAC, 12/24VDC, 110VAC etc.

PS. The solenoids assembled with the valves are optional, for the specific solenoids specifications refer to the irrigation solenoids section of this catalogue. Option of 12/24VAC, 12/24VDC.6-40VDC Latch, 110VAC ,220VAC etc

The superiority to purchase the whole valve with solenoid in our company:

1)Regarding to the price, overall buy must buy cheaper than separate.And also the cost of shipment will be cheaper if you have to let us send the solenodis to the other valves factory to assemble.

2)Regarding to the delivery time. If we produce the overall we can send them together and will be faster than the sending them separate by different factory with different delivery time and production scheduling..

3)Regarding to the quality assurance, it is most important because we can test them overall and it will be easier to find the problem and repair them fast..If have the problem we can solve them much easier and more convenience..Or as you know if you have the different solenoids and valves supplier, if you have problem found in your company it will be much more inconvenience and also will cost a lot of time and money to change from two different suppliers..That will be a big problem..Anyway some problem if we produce the overall we can found them more easier such like the wrong dimensions,wrong performance..Because some problem may not be tested by separate testing.

4)For us more experience both in producing the soelnoids and valves will be a big quality assurance for all the customers and also easier to find the problem and research and development the new products..

Features:

1) Option of without manual, with manual or flow control

2) Valve body made of Aging-proof Corrosion-Resistant Reinforced Nylon for the long life duration.

3) Rugged synthetic rubber diaphragm provide the lead-proof seal

4) Special valve configuration with the self-cleaning function, debris-tolerant.

5) Self-aligning bonnet permits fast and easy maintenance

6) High-flow, low-friction-loss design.

Specifications:

Calibre inch | Max Pressure | Flow Rate | Rated Voltage | Initial Power | Holding Power |

1/8 | 0.069 ~ 1.05 | 12 ~ 120 | 24VAC / 50Hz | 10.5VA | 5.5VA |

Pressure Loss

Flow Control | Pressure Loss |

12 | 32 |

20 | 34 |

40 | 31 |

60 | 23 |

80 | 25 |

100 | 38 |

120 | 55 |

- Q: How about the valve?

- In 1998 began the formal production of valves. As the company expanded in size, in September 2003, changed its name to the British HV VALVES LIMITED (HUDDERSFIELD), referred to as the United kingdom. The design and production of various types of valves, widely used in power, oil, chemical, offshore platforms and other fields, with its excellent quality and service to win the praise of the vast numbers of users.

- Q: Where is the Shanghai valve? What brand is good?

- Shanghai Dapu Valve Co. Ltd.Amico jiekelong shield, doing a good job

- Q: How to suppress the valve?

- How does the valve press the pressure test pump?. How much pressure do you need to use the pressure pump for the corresponding specifications?. There is a specially suppressed machine pressure test pump. How much pressure do you need to use the pressure pump for the corresponding specifications?

- Q: 1/2, what does 1/4 valve mean? I don't understand. What does this number mean? Have a valve to introduce me, do not copy a pile of online introduction, I want to concise

- 1/2, 1/4 valve is our usual popular name. "1/2" and "1/4" refer to the size of the valve bore, in inches. And there are 3/4, 3/8 to 24, 30, and 36 inches. Relative to our country on the valve bore that is "DN."". There are about 1 inches =25.4MM conversion, so in general we are 1 inches of the valve is DN25 valve.

- Q: Is the heat jacketed valve fitted with flanged flanges?

- Insulation valve is the standard valve, just in order to ensure the link bolt flange to super space, usually a large ball than normal level, such as the use of the path is DN80 flange, flange is DN100, so is the standard, but the size of flange connecting with other valves are not the same.

- Q: What are the valve types H, F, and Y? What are the meanings of these 3 letters?

- Please refer to "JB/T308-2004 valve model preparation method"Sealing surface material codeH Cr13 stainless steelF fluoroplasticY cemented carbide

- Q: The general signal valve installation, or other valve installation is not installed with the groove flange clamp hoop Yucca or direct way? What's the convenient way to install the following diagram? I don't understand. Neither groove, flange nor hoop. Thank you, sir!

- The installation of the signal valve is in accordance with GB50261-2005The 5.4.6 signal valve shall be installed on the pipe in front of the flow indicator, and shall not be less than 300mm from the flow indicator.The other valve control valve installation, specification, type and location of installation shall comply with the design requirements, the installation direction should be correct, control valve should be clean, no blockage, no leakage; the main control valve should be added headstock logo, the control valve cover shall be provided to indicate position of the mark in the position.1. The installation of the exhaust valve shall be carried out after the pressure test and the flushing of the system pipe. The exhaust valve shall be installed at the top of the water distribution dry pipe and the end of the distribution pipe, and no leakage shall be ensured.2, the valve flow direction should be consistent with the direction of flow in the water supply pipe, water inlet side of the filter is installed, and should be installed in the control valve; the adjustable valve should be installed horizontally, the valve cover should be upward; the proportional valve should be installed vertically: when the level of installation, the valve orifice hole single breath we should double down, breathing valve whose orifice should be in a horizontal position.3 other control valve should be installed to keep a certain distance, to facilitate maintenance and management, installation of multifunctional pump control valve itself with pressure gauge, pressure gauge should be installed in the adjacent parts; import should be prevented in the back before the installation or use of the filter with filter backflow preventer, backflow preventer at both ends the valve should be installed separately, and at least one end of the flexible joint should be installed;

- Q: What is a heavy body valve?

- You should be asking what a heavy-duty valve is.This is only in the ordinary gate valve and cut-off valve on the distinction. Nowadays, ordinary gate valves and cut-off valves are divided into heavy-duty ones. Medium and light three kinds ~!

- Q: What are the general types of valves?

- Valve is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Function and use(1) cut off categories: such as gate valve, globe valve, plug valve, ball valve, butterfly valve, needle valve, diaphragm valve and so on. Cut off valve, also known as closed-circuit valve, stop valve, whose role is to connect or cut off the pipeline medium.Check valves, also known as check valves or non-return valves, check valves belong to an automatic valve, its role is to prevent the pipeline medium backflow, to prevent the pump and drive motor reversal, as well as the leakage of container media. Pump water off the bottom valve check valve also belongs to class.The function of the relief valve is to prevent the medium pressure in the pipeline or device from exceeding the required value so as to achieve the purpose of safety protection.Control valve, throttle valve and pressure reducing valve, its role is to regulate the media pressure, flow and other parameters.(2) vacuum type: such as vacuum ball valve, vacuum flapper valve, vacuum air charging valve, pneumatic vacuum valve, etc.. Its function is to change the direction of the air flow in the vacuum system, adjust the air flow rate, cut off or connect the vacuum system of the pipeline, and the component is called the vacuum valve.(3) special uses such as pigging valves, vent valves, drain valves, exhaust valves, filters, etc.. The exhaust valve is an essential auxiliary component in the pipeline system. It is widely used in boilers, air conditioners, petroleum, natural gas, water supply and drainage pipelines. Often installed in the commanding heights or elbows, etc., to exclude excess gas pipeline, pipe road to improve the use of efficiency and reduce energy consumption.

- Q: How can the material be checked by valve approach? What experiments do you need?

- May refer to the valve pressure test principle and the pressure test matters needing attention.(1) in general, the valve shall not be subject to strength test, but the body and bonnet shall be subjected to strength tests after the repair of the valve body and bonnet or corrosion damage. For the relief valve, the constant pressure and seat return pressure and other tests shall be in accordance with the specifications and the relevant regulations.(2) the installation of the valve should be done for strength and tightness test. Low pressure valve sampling 20%, if not qualified should be 100% of the inspection; medium and high pressure valve should be 100% of the inspection.(3) the installation position of the valve shall be in the direction of easy inspection during the test.(4) welding connection valve, not with blind plate pressure test can be used when the cone seal or O ring seal pressure test.(5) when hydraulic test, the valve air will be excluded as much as possible.(6) the pressure should be increased gradually during the test, and the pressure will not be sudden and sudden.(7) strength test and sealed test duration is generally 2~3min, important and special valves should last 5min. Small caliber valve test time can be a little shorter, large caliber valve test time can be longer. During the test, the test time can be extended if in doubt. Strength test, does not allow the body and bonnet sweating or leakage. Sealing test, the general rotor valve only once, the safety valve, high pressure valve and other raw valve to be carried out two times. When testing for the low pressure, large diameter valve is not important and there are provisions to allow leakage of the valve, allowing a small amount of leakage; the common valve, power station valve, marine valves and other valve requirements vary on leakage requirements according to relevant regulations.

Send your message to us

plastic masoneilan control valves 1/8'' inch

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords