Butterfly Valve Bilateral Metal Hardware Sealed Electric on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

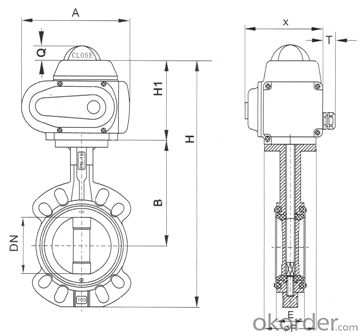

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What's the valve specification DN20?

- Valve specification DN20 is 6.The inches in the valve refer to inches, 1 inches =25.4mm, and 1 inches =7.62 cents.The corresponding relation between inch and DN and mm is:4 is divided into corresponding caliber DN15, that is, diameter 15mm;6 is divided into corresponding caliber DN20, that is, diameter 20mm;1 inches for the corresponding caliber DN25, that is, diameter 25mm;1.2 inches for the corresponding caliber DN32, that is, diameter 32mm;1.5 inches for the corresponding caliber DN40, that is, diameter 40mm;2 inches for the corresponding caliber DN50, that is, diameter 50mm;2.5 inches for the corresponding caliber DN65, that is, diameter 65mm;3 inches for the corresponding caliber DN80, that is, diameter 80mm;4 inches for the corresponding caliber DN100, that is, diameter 100mm;5 inches for the corresponding caliber DN125, that is, diameter 125mm;6 inches for the corresponding caliber DN150, that is, diameter 150mm;8 inches for the corresponding caliber DN200, that is, diameter 200mm;10 inches for the corresponding caliber DN250, that is, diameter 250mm.

- Q: For example, the knife gate valve, PZ73X-10C, DN50 torque is 5, torque is what role? What units?

- Unit: Newton M. torque is the minimum torque used to turn on the valve. It is the force that opens the valve!The valve that indicates the opening of the PZ73X-10C DN50 requires 5 meters of force.

- Q: What is the main function of the valve?

- Valve is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure. Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow.

- Q: What are the advantages and disadvantages of this method? Are there any other ways to adjust the flow rate?

- With the advantages of the pump outlet valve adjustment, 1, you can control the pump outlet pressure, 2, you can control the motor current is not more than the process conditions, 3, control motor power, to ensure the normal operation of the pump.

- Q: What should be checked before using the valve?

- The valve must be visually checked before installation1, valve opening and closing position should meet the following requirementsThe valve, the cut-off valve, throttle valve, regulating valve, butterfly valve, foot valve, the valve is in full closed positionPlug valves and ball valves should be in full open position? diaphragm valve should be in the closed position, and can not be too tight to prevent damage to the diaphragmCheck valves shall be closed and secured2, the valve shall not be damaged, missing parts, corrosion, nameplate shedding and other phenomena, and the valve body shall not be dirty3, both ends of the valve should be protected. Handle or handwheel should be flexible and light, and must not be stuck4, valve body casting, the surface should be smooth, no cracks, blisters, lock, pores, burrs and other defects; outside valve forging, the surface should be free of cracks, interlayer, double skin, scar defect

- Q: The total valve of my natural gas was closed by the attitude I tried. Now I can't open it. I need to use gas. Who knows how to drive it? What skills do I have? I'm talking about the main valve.

- General domestic weather is more ball valve, counterclockwise turn 90 degrees can.

- Q: What do letters represent in the QF-2 and PX-32 valve models?

- You check it on the national standard! One is accurate!

- Q: What is the KVS in the valve parameter?

- KVS meaning in valve parameters:Kvs is the coefficient of flow (also called circulation capacity).Kvs refers to both ends of the valve pressure difference of 0.1MPa, water density of 1g/cm^3, when the valve fully open flow. It is an important parameter of the control valve, reflecting the capacity of the control valve.Flow coefficient is a unit of time, in the test conditions, the pipeline to maintain a constant pressure, pipe flow through the valve mass flow, or mass flow. That is, the maximum flow capacity of the valve. The greater the value of the flow system, the smaller the pressure loss when the fluid passes through the valve. The CV value of the valve shall be determined by test and calculation.

- Q: How do you calculate the flow of the valve?

- Valve flow calculation value is very vague, pipe pressure, back pressure, medium viscosity, medium temperature, valve structure, and so on, will affect the calculated value.

- Q: Can the angle valve of York central air conditioner be replaced by other valves?

- Definitely. But I want you to tell me what you're doing, or give me a picture. I can give you some advice

Send your message to us

Butterfly Valve Bilateral Metal Hardware Sealed Electric on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords