Valve with Good Price from Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

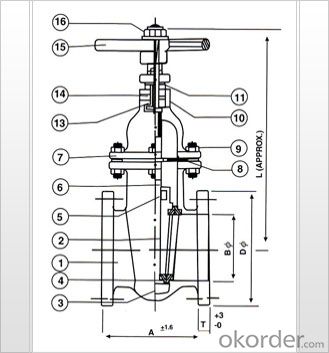

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: Proportional valve why than other small pipeline valves

- 3.8 valveGraphical representation of numbers, names, symbols3.8.1 angle valve at room temperature3.8.2 cold angle valve for low temperature use3.8.3 stop valve at room temperature3.8.4 ball valve often 9 temperature3.8.5 valve at room temperature3.8.6 butterfly valve at room temperature3.8.7 check valve flow from blank triangle to non empty triangle3.8.8 pressure reducing valve, small triangle for high voltage end3.8.9 throttling valve is needle valve3.8.10 three-way valve for normal temperature use3.8.11 four way valve used at normal temperature3.8.12 safety valve spring type safety valve3.8.13 trap actual drawing, you do not have to draw arrows3.8.14 inflator, cold box, little gas huff and puff, safe useValve for normal temperature of regeneration valve of 3.8.15 reverse stop valve3.8.16 reverse loading cold angle valve

- Q: What are the valves at home?

- Valve used in the family is commonly used, the following are several:On the water pipe are: total table of the ball valve (32mm), in charge of the (25mm), as well as for the toilet, washbasin, water heater angle valve (20mm).Other commonly used gas pipelines, valves, pressure reducing valves and the like.

- Q: I would like to ask how the valve entry, for a new pair, really difficult, what cutaway view, there are other, just contact the valve less than a week, and sometimes it is really difficult to understand. Forget the experienced teacher can be generous with your criticism to later, indebted forever, learn the valve Comrades some help.In a company CAD to relatives as soon as possible to a company, and then slowly improve, I do not know what is the request of the novice, and how to start as soon as possible, I am learning routine is: give me a set of valve design drawings, and then I paint it on, do not understand the structure and workshop look. I wonder if you have any good learning methods that can be referred to and supplemented by younger brother

- Valve range can be very wide, each company to do valve products are not the same;According to the company's production capacity and technology,Valve parameters to:1, valve spool material,2, connection mode (thread, welding, flange, clamp, socket welding, fast loading, etc.),3 caliber,4, medium (water, steam, oil, gas, liquid, etc.),5, temperature (medium temperature, environmental temperature),6, pressure (MPa, LB, K, etc.),7, configuration (executor and its accessories);A lot of valve requirements and this almost. Can also be selected according to the ideal valve function of customers.Switching type:Ball valve, butterfly valve, globe valve, gate valve, needle valve, etc.Regulatory type:Pneumatic valve, electric valve (adjustable type can be divided into: regulating temperature, regulating pressure, regulating flow), and so on

- Q: What does "1/2" mean on the valve?

- Indicates that the ends of the valve are 1/2 inches in diameter. 1 inches is converted to metric system of 25.4 millimeters.

- Q: Is there any problem with connecting the geothermal valves with other geothermal pipes?

- Material is the same, the fuse will not cause shrinkage when you can use

- Q: 1) the valve plate, valve gate valve, the difference (my personal understanding is that if it is on the ball, called the valve, if the valve is called the gate, is actually a meaning in different valve called, please help me understand it right?)2) valve clack. What's the spool?3) the valve seat is welded inside the valve, or is it directly installed inside without welding?4) when opening the valve, if the valve seat is not welded, then, under the pressure of the medium, why not open the seat?.5) excuse me, pressure self sealing (my personal understanding is that when the valve is closed, the valve plate and valve seat depend on the pressure of the media, and they fit together to seal the effect

- 1. can be understood that way2, check valves, stop valves, and throttle valves are called valves3., welding, thread, and there is a cylindrical indentation, as well as plastic deformation press in4, without opening, there is a sphere or other block, open the moment, the pressure will come down, the media through the channel, attack or blocked by the ball, huh, huh5, the pressure self tight refers to the middle flange, where the greater the pressure, the more reliable sealing, within a certain rangeWhen the cut-off valve diameter is less than 150, the medium is low, the inlet is higher and the outlet diameter is greater than 200Some of them are self locking by thread, and some of the globe valves are equipped with locking devices

- Q: Is the valve galvanized?

- If you need it, you can order it. Any valve will do

- Q: What does 1/2 mean in valve specification?

- 1/2 is American Standard, said 1/2. Equivalent to GB DN15, nominal diameter 15mm, indicating that the diameter of the pipe is 15mm. In the plumbing industry, it's called 4 points.Valve specifications in common use:Say: American Standard - GB4 points - 1/2 - DN156 points - 3/4 - DN201 inches - 1 - DN251 inches 2 - 1 and 1/4 - DN321 and a half - 1 and 1/2 - DN402 inches - 2 - DN50

- Q: How big valves are used in the DN90 pipeline?

- If you use a 97 tube, the inner diameter of 89- phi 90., nominal pressure is low, then try to use DN80, DN80 valve diameter of 80, you can try butt welding

- Q: Which valves are installed in a directional manner?

- Depends on the specific valve is one-way seal or two-way seal?

Send your message to us

Valve with Good Price from Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches