Valve with Competitive Price from Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

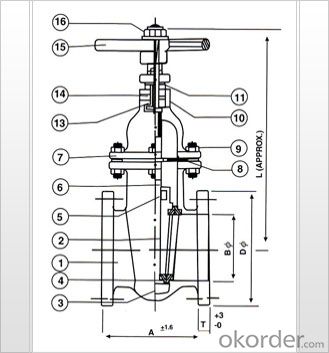

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: I would like to ask how the valve entry, for a new pair, really difficult, what cutaway view, there are other, just contact the valve less than a week, and sometimes it is really difficult to understand. Forget the experienced teacher can be generous with your criticism to later, indebted forever, learn the valve Comrades some help.In a company CAD to relatives as soon as possible to a company, and then slowly improve, I do not know what is the request of the novice, and how to start as soon as possible, I am learning routine is: give me a set of valve design drawings, and then I paint it on, do not understand the structure and workshop look. I wonder if you have any good learning methods that can be referred to and supplemented by younger brother

- I was about 08 years of contact valve, indeed many, but a company, all products will not have, are designed to do certain types of valves, such as for HVAC, or petrochemical, some other valves used in engineering, will do the purchase, so you only according to the company's products study on the line, need to learn what, what, high efficiency.If you do the design, you have to learn a lot of things: "mechanical design manual" and "valve design manual" is essential, often used;Of course, functional things are the basis, that is, the structure, the work principle must be obtained first, in order to do relevant design and improvement;First of all, the structure design, CAD must learn, three-dimensional software also have to learn one, Solidworks, Peo/E, UG, Catia can be;Second, strength analysis is necessary, so in mathematics, mechanics, mechanical design things to learn solid; can make strength analysis with finite element analysis software, need to learn, software Comosworks, Ansys;Third, the valve design will have fluid aspects, flow design, flow capacity, flow characteristics of the study, to study fluid mechanics, heat transfer, etc., CFD software has Fluent, Ansys, CFX, Star-CD;In addition, materials and technical aspects should be learned.Slowly, I also step by step by side with coming.Hope to be of help to you.

- Q: What is the choice of pneumatic valve or electric valve for ultrafiltration inlet control valve?

- Pneumatic valve compared to the electric valve, the valve can be the same, rubber lined butterfly valve or other valves, pneumatic valve opening speed (Basic 1 second can be fully open), the price is lower than the electric valve. But there must be process air (4-6bar compressed air). According to my experience, if the scene has compressed air, it is recommended to use pneumatic valve, if there is no compressed air, it is recommended to use electric (electric valve expensive, open valve slow).

- Q: What does the 4 point valve mean?

- The caliber is DN15's valve. What valves do you need?

- Q: Hydrant valve leaks, how do you close other valves? Specific steps?

- Hello my name is Baidu know the long days of high water leakIn the vicinity of a common fire hydrant, there is a valve, which is convenient for fire hydrant maintenance, because fire hydrant repairs need to close the water source. Look around, it should be easy to find the valve. Switch valve is very simple, and the direction of the twist screw is the same, clockwise turn off, counterclockwise is open. Closed valve, fire hydrant will not leak, you can feel relieved to repair. I guess your fire hydrant is sealed rubber pad, aging causes leakage, it is a common disease of fire hydrants.

- Q: What's the name of the valve?

- This is the discharge valve, the lower part of the handle protruding part of the valve is the sealing device. The overall material should be brass, which is typically made by equipment manufacturers.

- Q: What are the major brands of valves abroad?

- I say a few familiar: Tyco (the world's largest manufacturer of valves, the valve can provide almost all of it) Fuchs (a bit like, with the whole series of Tyco products)Blake (mainly butterfly valve, ball valve, chemical and water treatment applications up)Gaemi (diaphragm valve is doing very well) KSB (mainly in the power industry valve, globe valve, etc.)

- Q: What is the purpose of the valve?

- 3. Change the direction of the medium flow in the pipeline. Such as the distribution of valves, three way cock, three or four ball valve etc..4, stop the medium back flow in the pipeline. A variety of different structures such as check valve, valve etc..5, separation medium. Such as different structures of steam traps, air traps and so on.

- Q: Which valves are installed in a directional manner?

- Very simple answer to your valve, in addition to gate valve and butterfly valve (single line up, first closed), such valves are not directional, and other have

- Q: What is the difference between a stop valve (a power station valve) and other valves?

- Power station cutoff valve advantages editor1., the fluid resistance is small, and the coefficient of resistance is the same length as the pipe section.2., simple structure, small size, light weight.3., reliable and reliable, the current gate valve sealing surface materials widely used plastic, good sealing, vacuum system has also been widely used.4 easy operation, open and close rapidly, from fully open to fully closed as long as 90 degree rotation, facilitate remote control.5., easy maintenance, simple valve structure, sealing ring is generally active, disassembly and replacement are more convenient.6. in full open or full closed, the ball and valve seat sealing surface and dielectric isolation, the media through, it will not cause erosion of the valve sealing surface.7., a wide range of applications, from small diameter to a few millimeters, large to several meters, from high vacuum, high pressure can be applied.

- Q: What's the material of j41h-16p's valve?

- Stop valve characteristics:(1) the structure is simpler than the gate valve, and the manufacture and maintenance are more convenient.(2) the sealing surface is not easy to wear and scrape, good sealing, when opening and closing, there is no relative sliding between the valve and the sealing surface of the valve body, so the abrasion and abrasion are not serious, the sealing performance is good, and the service life is long.(3) when opening and closing, the valve stroke is small, so the cut-off valve height is smaller than the gate valve, but the structure length is longer than the gate valve.(4) the opening and closing moment is big and the opening and closing are more strenuous.(5) large fluid resistance, due to the valve in the medium channel is tortuous, large fluid resistance, power consumption.(6) the flow direction of medium nominal pressure PN is less than or equal to 16MPa, commonly used downstream, medium from the valve under the direction of flow; nominal pressure PN = 20MPa, using reflux, medium from the valve on the downstream direction to increase the seal. When used, the cut-off valve medium can only flow in one direction, can not change the direction of flow.(7) when fully open, the disc is always subject to erosion.

Send your message to us

Valve with Competitive Price from Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords