Butterfly Valve with Plastic Handle Made in China on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

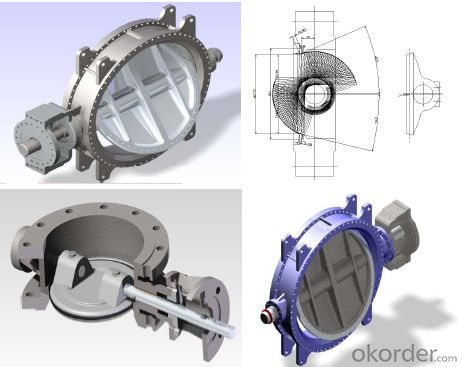

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

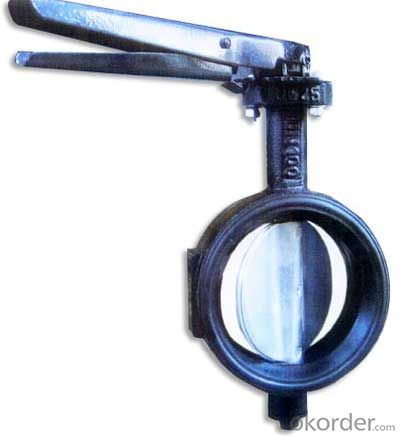

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Z11H/Y forged steel gate valves H/Y what does that mean?SZ45H S what do you mean?Blow 2Z41YGY-40P, what do you think?What does NKZ61H vacuum valve NK mean?What does DS/Z64H water seal valve DS mean?Specific valve number how to see ah, detailed information, thank you!

- The meaning of valve number:Valve type Z, J, L, Q, D, G, X, H, A, Y and S respectively: gate valve, globe valve, throttle valve, ball valve, butterfly valve, diaphragm valve, plug valve, check valve, safety valve, relief valve, drain valve.The connecting codes for valves are 1, 2, 4, 6, 7, respectively: internal thread, 2, outer thread, 4, flange, 6, welding, 7, pair.Valve transmission mode code 9, 6, 3, respectively, said: 9, electric, 6, pneumatic, 3, turbo worm.Body material Z, K, code Q, T, C, P, R and V respectively: grey cast iron, malleable cast iron, ductile iron, copper and alloy, carbon steel, stainless steel, chrome nickel chromium nickel molybdenum stainless steel, chromium molybdenum vanadium steel.Seat sealing or lining R, T, X code, S, N, F, H, Y, J, M, W respectively: austenitic stainless steel, copper alloy, plastic, rubber, nylon plastics, fluorine plastic, Cr stainless steel, hard alloy, rubber lining, Monel alloy, valve body material.

- Q: What is the choice of pneumatic valve or electric valve for ultrafiltration inlet control valve?

- Pneumatic valve compared to the electric valve, the valve can be the same, rubber lined butterfly valve or other valves, pneumatic valve opening speed (Basic 1 second can be fully open), the price is lower than the electric valve. But there must be process air (4-6bar compressed air). According to my experience, if the scene has compressed air, it is recommended to use pneumatic valve, if there is no compressed air, it is recommended to use electric (electric valve expensive, open valve slow).

- Q: If the valve in the pipeline throttle, such as open and open 50%, the valve before and after the pressure of how to calculate, how the flow changes?

- Well, it's not easy. And you do not give the specific structure of the valve, so there is no way to talk about the calculation. The simplest way is to install the pressure gauge and the flow meter on both ends of the valve, and read the data directly.

- Q: Which valves are used in the power station?

- Power gate valve, also known as power station valve, is mainly used in various pipelines of fire power plants, cutting off or connecting pipeline medium.Applicable medium: non corrosive media such as water and steam. Compared with other valve products, the valve is characterized by high temperature and high pressure and unique self sealing design. The higher the pressure, the more reliable the seal is. Because of its performance, technical characteristics and special working conditions, the products can not be replaced by other products.Compared with other valve products, the gate valve of the power station is characterized by high temperature and high pressure. If only the pressure is lower than that of the universal valve, the temperature is lower than that of the general valve. Because of its performance, technical characteristics and special working conditions, the products can not be replaced by other products.

- Q: What valve does the high pressure by-pass valve DN254 * 800 belong to?

- High pressure bypass valve DN254 * 800 belongs to bypass valve.Function of bypass systemThe turbine by-pass device mainly has three functions of starting and overflowing:1 in the cold, warm and hot, the bypass system can realize the optimal unit start-up and shut-down in turbine operating conditions, start and stop curve can meet the requirements, two types of automatic and manual operation, with the establishment of the boiler steam temperature and steam turbine components. To shorten the start-up time.2. when the turbine is tripped, the bypass system can operate at a high speed and reach full open position.3., when the turbine load changes, the by-pass system has the regulating function, and the safety valve action can be avoided and the operation stability of the boiler can be improved when the instantaneous change of the moving state.The function of the bypass control valve:The main function of steam turbine bypass system is high pressure steam adjusting throttling and superheated steam cooling. The bypass valve to perform these functions at the same time and in low noise, small vibration, valve resistance to achieve its goal of temperature and pressure loss under the condition of touch.

- Q: Yongde jiekelong valves and valves of the good faith

- If I choose, I choose Amico...After all, Amico did 20 years of copper valves...Moreover, the valve of this brand, Amico more people know...Jake, Amico has been imitated, even the same type..Of course more than jiekelong imitate slightly, there are other more or less imitation point valve...But I wonder if you use a big valve or a small valve?,If it's a small valve, use Amico..Big valve, these two are expensive outrageous...You can discuss it when you have time...

- Q: What are the most common types of valves?

- Gate valve, ball valve, butterfly valve, stop valve, these are the most common, but also the largest amount

- Q: Why can't the clip type check valve be directly connected with the pipe mouth or other valves?

- The clip type check valve is made up of two discs to prevent backflow.If the clip check valve is connected to the other valve, the disc may touch the valve and cause the check valve not to be fully opened or closed. This is a preliminary analysis of "enter the valve", for reference only!

- Q: What is the diameter of a general pipe valve?

- In fact, the essence of the problem is the corresponding relationship between the nominal diameter and other dimensioning methods. Valves are generally marked with nominal diameter (DN***), such as DN150, DN100 and so on. There are many kinds of marking methods for pipes, such as outer diameter, inch inch, nominal diameter, etc.. Only when the other dimensioning is converted to nominal diameter, the valve and the pipe correspond to each other.

- Q: What's the material of j41h-16p's valve?

- Stop valve characteristics:(1) the structure is simpler than the gate valve, and the manufacture and maintenance are more convenient.(2) the sealing surface is not easy to wear and scrape, good sealing, when opening and closing, there is no relative sliding between the valve and the sealing surface of the valve body, so the abrasion and abrasion are not serious, the sealing performance is good, and the service life is long.(3) when opening and closing, the valve stroke is small, so the cut-off valve height is smaller than the gate valve, but the structure length is longer than the gate valve.(4) the opening and closing moment is big and the opening and closing are more strenuous.(5) large fluid resistance, due to the valve in the medium channel is tortuous, large fluid resistance, power consumption.(6) the flow direction of medium nominal pressure PN is less than or equal to 16MPa, commonly used downstream, medium from the valve under the direction of flow; nominal pressure PN = 20MPa, using reflux, medium from the valve on the downstream direction to increase the seal. When used, the cut-off valve medium can only flow in one direction, can not change the direction of flow.(7) when fully open, the disc is always subject to erosion.

Send your message to us

Butterfly Valve with Plastic Handle Made in China on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches