Butterfly Valve Stainless Steel Threaded Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

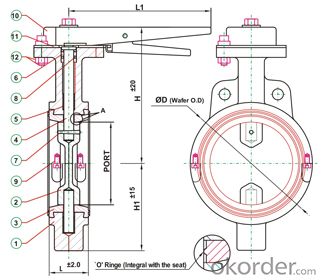

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Where is the hydrant main valve?

- There is a gate valve at the elbow below the hydrant

- Q: How about leaking water pipe valve?

- It depends on where the place is leaking.1, if it is household valveA, the valve and pipe connections at the leakage, in the connection, do not rub tape (the best counter clockwise direction, so that when the valve is connected, the more twisted the more tight) ;B, if the valve itself in the leak, there are ways, it is necessary to open the valve, in which to add sealed or O ring, but it is recommended to replace a more convenient.2, if it is industrial valvesA, industrial valves leaking, if not the valve itself in the leak, then in the valve and pipe connections to join the sealing ring,B, if the valve itself is leaking, it is best to return to the manufacturer for maintenance, if not convenient, then only the manufacturers to come here for maintenance.

- Q: What does the 4 point valve mean?

- Commonly used valves, pipes in the 4 points, 6 points, an inch, is the earliest use of the length of the British unit, metric units are 15, 20, 25 mm, and now people are also used to call 4 points, 6 points, an inch.1 inches =25.4 mm1 feet =12 inches1 inches =8 cents

- Q: What kind of valve is it? How do you see the status of the switch?

- Globe valve, not ball valveClockwise (Bell) needle to reduce the flow to the end of the shutdown, the counter clockwise to open. You can turn the multi circle plate will also lift up and down. The spindle, to the top is open, down to the edge off.The ball valve has a strip handle, the line is connected, and the cross is turned off

- Q: What's the difference between valves and valves without valves?

- The difference between a valve with and without a valve is that it has the advantage of having the valve exhaust. The advantage of the valve is that it can control the amount of exhaust and prevent the discharge of other fluids.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: What items and detailed procedures should be inspected for valve size inspection?

- Valve body structure length and flange size, GB size, the implementation of GB/T12221-2005. American Standard. (the American Society of mechanical engineers ASME B 16.10-2000).

- Q: What valve is the VENT?

- VENT generally use a check valve (resembling a screw, spring preload), also directly using the plugA two-way sealing type ball valve for example, in order to detect the leakage of the pressure after the end, also for pressing the cavity is convenient, usually in the body cavity external to the up position to open a checking leak, which is VENT.

- Q: What do you mean by the 16 bit coding of the valve type?

- Valve model is by the type of valve, valve drive, valve connection, valve structure, sealing material, valve body material code to indicate.1. Valve types are Z- gate valve, P- drain valve, Q- ball valve, D- butterfly valve, J- stop valve, etc.;2, the valve drive mode code by letters said, common 2- electric hydraulic, 9- electric, 6- pneumatic, 5- bevel gear drive, 3- turbo worm; manual do not need to write out3, the valve connection form code with letters to indicate, 1- internal thread, 2- external thread, 4- flange type, 6- welding, 7- pairs clamp type, 9- clamp, 0- card sleeve;4, valve structure code, for example: 0- 1- flexible gate valve, open bar wedge type single gate, 2- rising stem wedge gate, 3- parallel single gate, 4- double disk parallel, 5- dark pole single wedge gate, 6- dark bar wedge gate, dark 7- parallel single gate, 9- dark pole parallel gate;5, sealing materials or lining materials were used R- T- austenitic stainless steel, copper alloy, X- rubber, S- plastic, N- nylon, F- fluorine plastic, H-Cr series stainless steel, hard alloy Y-, J- rubber lining, Monel M-;6, the body material code Z- K- gray cast iron, malleable cast iron, Q- ductile iron, copper and T- alloy, C- steel, P- chromium nickel stainless steel, R- stainless steel chromium nickel molybdenum, chromium molybdenum vanadium steel V-.For example: electric, flanged, rod wedge gate valve, sealing surface material by direct processing, nominal pressure PN0.1MPa of the valve body is made of grey cast iron gate valve: Z942W-1 electric wedge gate valve.

- Q: What does valve 41F-40C mean?

- 4: refers to the flange connection;1: on behalf of the structure of the form, different valves have different meanings;F: the sealing material is fluoroplastic;40: nominal pressure is PN40bar;C: the valve body is made of carbon steel, but the valves above PN25 shall be omitted from CAccording to the incomplete model provided, it is estimated that the ball valve is Q41F-40

- Q: What's the advantage of using three way valves?

- The principle of three way valve:The most obvious three valves and other valves is the difference in appearance, three way valve has three channels, mainly used to change the medium to flow through valve three, which in addition to import A, B, C and reversing port of export, common valve is not capable of changing the flow direction of medium function. The flow direction of the medium can be determined according to requirements.

Send your message to us

Butterfly Valve Stainless Steel Threaded Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords