Butterfly Valve Stainless Steel Threaded Directional Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

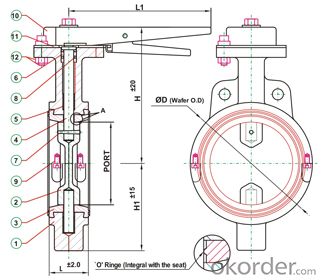

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What's the meaning of the "single valve"?

- Make is commonly known as "living joint". The utility model is a common pipe connecting piece which can be conveniently installed and disassembled.

- Q: What does the "XV" valve mean?

- XV if in front of the valve position, such as XV2211-011, then the XV indicates the switch valve, which is a representation of the Control Valve relative to the regulating valve.

- Q: Where is the filling portion of the valve?

- The valve stem and the body of the valve at the junction of the pressure cap, the pressure cap is filled inside.

- Q: I would like to ask this valve (not too clear, is it possible to call the valve), what is the specific name of the professional? Where can I buy it?

- From the appearance of it is not too good to say, if it is the valve, only one-way valve.The valve usually consists of the stem, spool, seat, body, seal, and so on. This figure feels more like a filter that connects a pressure vessel to an inlet or an inlet.I've seen a lot of filters like this, usually open with -drain filter inside. Play a role in the filter of some large magazines, you can change, more metal, the mother is relatively small (relatively large hole)

- Q: What are the main equipments for valve production?

- Press machine, CNC lathe, instrument lathe, drilling machine, machining center, assembly line, pressure test bench, plane, measuring instruments, etc.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: Can other valves be used instead of 10?

- An elbow, an outer wire, screw down the joint of the hose, the elbow is joined together.

- Q: Can the gas valves be switched off regularly?

- Now gas stoves have valves, do not have to pass the gas valve, valve, he has the life of the use of frequency, although the switch is not good, long time no operation is not good

- Q: What does the "Z45T-16" valve mean?

- Z - gate valve4 - flange connection5 - Dark pole, stem non lifting (gate valve structure)T - copper alloy, valve sealing face code16 - pressure code, 1.6MPaMaterial code for grey cast iron valves of nominal pressure less than or equal to PN16 shall be omitted in model preparation.May refer to JB/T 308 valve model compilation method

- Q: What's the name of the valve?

- This is not a valve, it is a pipe bender.

- Q: Where is it installed, what is the role, what is the material, and are there other alternatives instead of this effect?

- Valve packing in the valve under the gland to prevent leakage, you can use ordinary asbestos rope and butter emergency replacement

Send your message to us

Butterfly Valve Stainless Steel Threaded Directional Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords