Butterfly Valve with Plastic Handle Made in China on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow.

The closing mechanism takes the form of a disk.

Operation is similar to that of a ball valve, which allows for quick shut off.

Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required.

The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve.

Rotating the actuator turns the disc either parallel or perpendicular to the flow.

Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a) Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b) Soft seat. Replaceable. Increase of service life.

c) Double half shaft without pin.

d) Square and short neck.

e) Easy to stick scutcheon and cost saving.

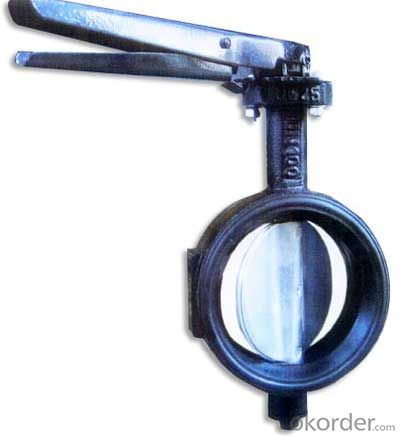

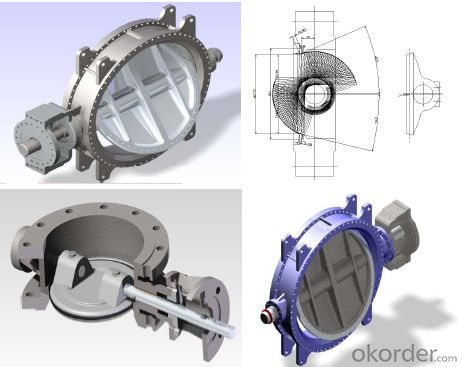

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1) What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2) How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

- Q: What do the Z, J, H and D represent in the valve type?

- :Austenitic stainless steel, copper alloy, plastic, rubber, nylon plastics, fluorine plastic, Cr stainless steel, hard alloy, rubber lining, Monel alloy, valve body material

- Q: What kind of industry does valve belong to?

- Valve is the valve, regardless of other sectors

- Q: What valves are needed on the construction site?

- Order valve flow1, customers have special requirements for products, must provide the following instructions in the contract: a) b) the length of the structure connection form C) nominal diameter, full size, shrinkage, pipe size d) using medium and temperature and pressure range E) test, inspection standards and other requirements.2, the factory can be configured according to customer specific requirements of various driving devices.3. If the customer provides the type and model of the valve to be determined, the customer shall correctly explain the meaning and requirements of the model and sign the contract on the condition that both the supply and demand sides agree.4, futures, order customers, please call the letter in detail to tell you the required valve model, specifications, quantity and delivery time, location, factory information, billing information, delivery address. And in accordance with the total amount of 20% of the predetermined amount or full amount of money, timely import our factory account, and the rest of the payment before shipment, import, in order to arrange delivery in time.

- Q: G what's the meaning of the valve?

- Valve with other function or with other special mechanism, fill in a Chinese language before the valve type code number

- Q: What valve is the FCV?

- It's FCU, Fan, Coil, Unit, fan coil valves

- Q: What courses in the University involve valves?

- Fluid mechanics, "material mechanics", "mechanical design" and other courses on the design of the valve are helpful.

- Q: 1/2, what does 1/4 valve mean? I don't understand. What does this number mean? Have a valve to introduce me, do not copy a pile of online introduction, I want to concise

- 1/2 is 4 points caliber, =15mm 1/4 is 2 points, caliber concise

- Q: 1) the valve plate, valve gate valve, the difference (my personal understanding is that if it is on the ball, called the valve, if the valve is called the gate, is actually a meaning in different valve called, please help me understand it right?)2) valve clack. What's the spool?3) the valve seat is welded inside the valve, or is it directly installed inside without welding?4) when opening the valve, if the valve seat is not welded, then, under the pressure of the medium, why not open the seat?.5) excuse me, pressure self sealing (my personal understanding is that when the valve is closed, the valve plate and valve seat depend on the pressure of the media, and they fit together to seal the effect

- 1. can be understood that way2, check valves, stop valves, and throttle valves are called valves3., welding, thread, and there is a cylindrical indentation, as well as plastic deformation press in4, without opening, there is a sphere or other block, open the moment, the pressure will come down, the media through the channel, attack or blocked by the ball, huh, huh5, the pressure self tight refers to the middle flange, where the greater the pressure, the more reliable sealing, within a certain rangeWhen the cut-off valve diameter is less than 150, the medium is low, the inlet is higher and the outlet diameter is greater than 200Some of them are self locking by thread, and some of the globe valves are equipped with locking devices

- Q: HH valve company in the United Kingdom, how about the valve?

- Our factory boiler has this brand of valve, used for many years, has been no problem, really good.

- Q: What are the types of valves?

- 1.2.1 sort by pressurex09 (1) vacuum valve operating pressure below standard atmospheric pressure valvex09 (2) low pressure valve nominal pressure PN is less than or equal to 1.6 MPa valve.x09 (3) medium pressure valve nominal pressure PN, 2.5, 4, 6.4 MPa valvex09 (4) high pressure valve nominal pressure PN 10.0~80.0 MPa valvex09 (5) high pressure valve nominal pressure PN = 100 MPa valve.1.2.2 classification by dielectric temperaturex09 (1) high temperature valve for medium working temperature T > 450 degrees of the valvex09 (2) medium temperature valve for medium temperature 120 degrees valvex09 (3) at room temperature valve for medium temperature -40 = t = 120 DEG C of the valve.x09 (4) low temperature valve for medium temperature -100 = t = -40 C of the valve.x09 (5) ultra low temperature valve for medium working temperature T < -100 DEG C valve

Send your message to us

Butterfly Valve with Plastic Handle Made in China on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches